Method of testing contact resistivity of passivated contact structure

A technology of contact resistivity and contact structure, applied in the field of solar cells, can solve the problems of complex photolithography mask process and RIE process, difficult to manufacture in large quantities, difficult to use, etc., and achieves improved fitting determination coefficient and good accuracy. , the effect of the same path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with example the present invention is described in detail.

[0047] The specific embodiment is only an explanation of the present invention, not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this description, but as long as they are within the scope of the claims of the present invention inside are protected.

[0048] A kind of method for testing the contact resistivity of passivation contact structure of the present invention, its technical scheme is: comprise the following steps:

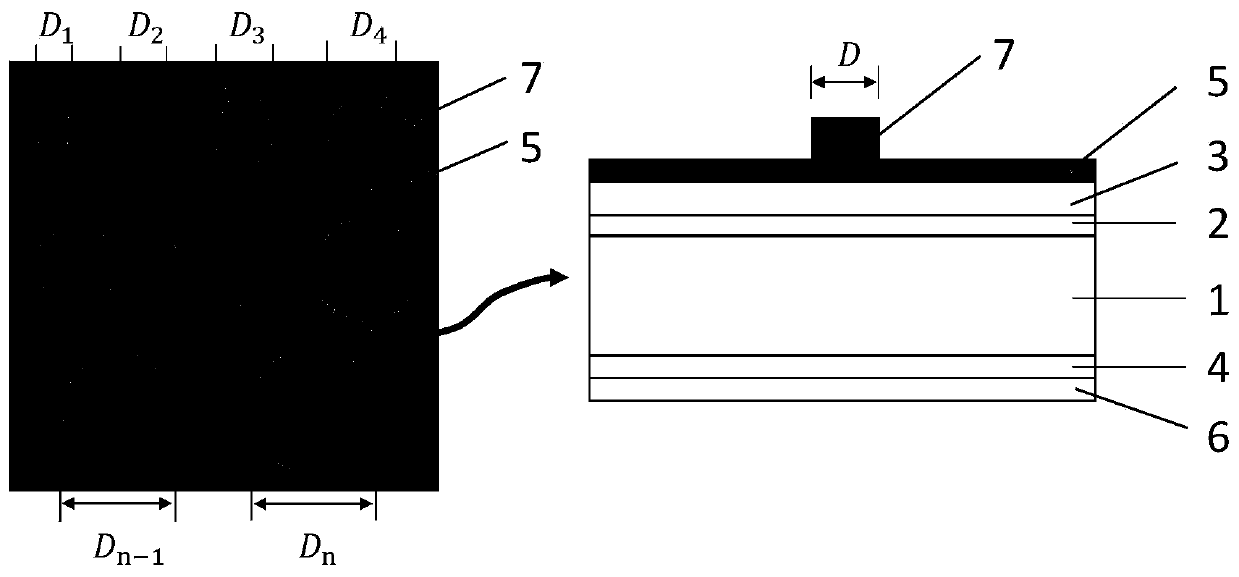

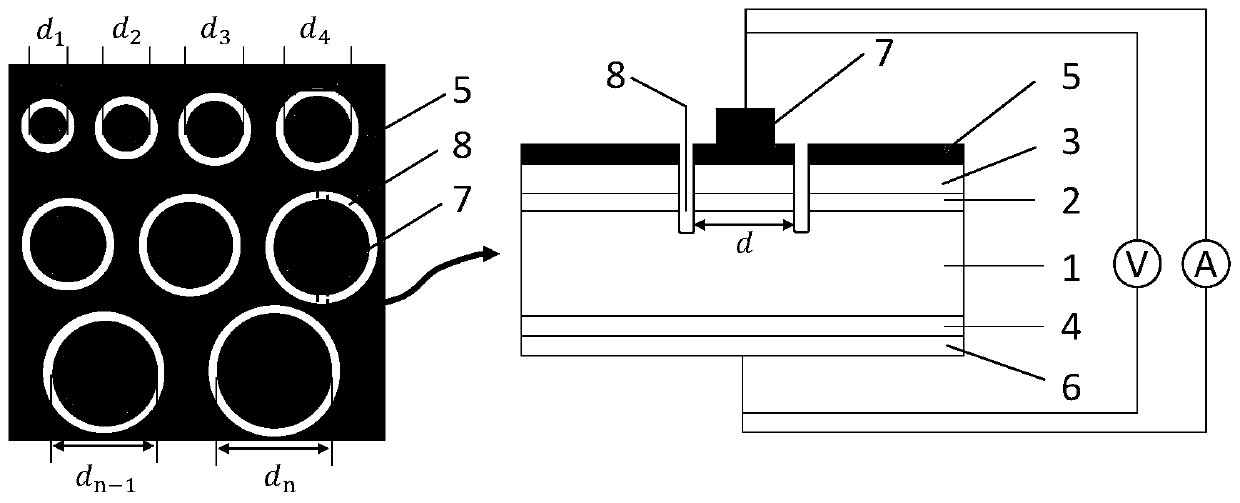

[0049] (1) Grooving is performed around circular point electrodes with different diameters on the battery sheet to form circular groove structures with different inner diameters; wherein, the circular groove structures extend longitudinally to the inside of the silicon substrate;

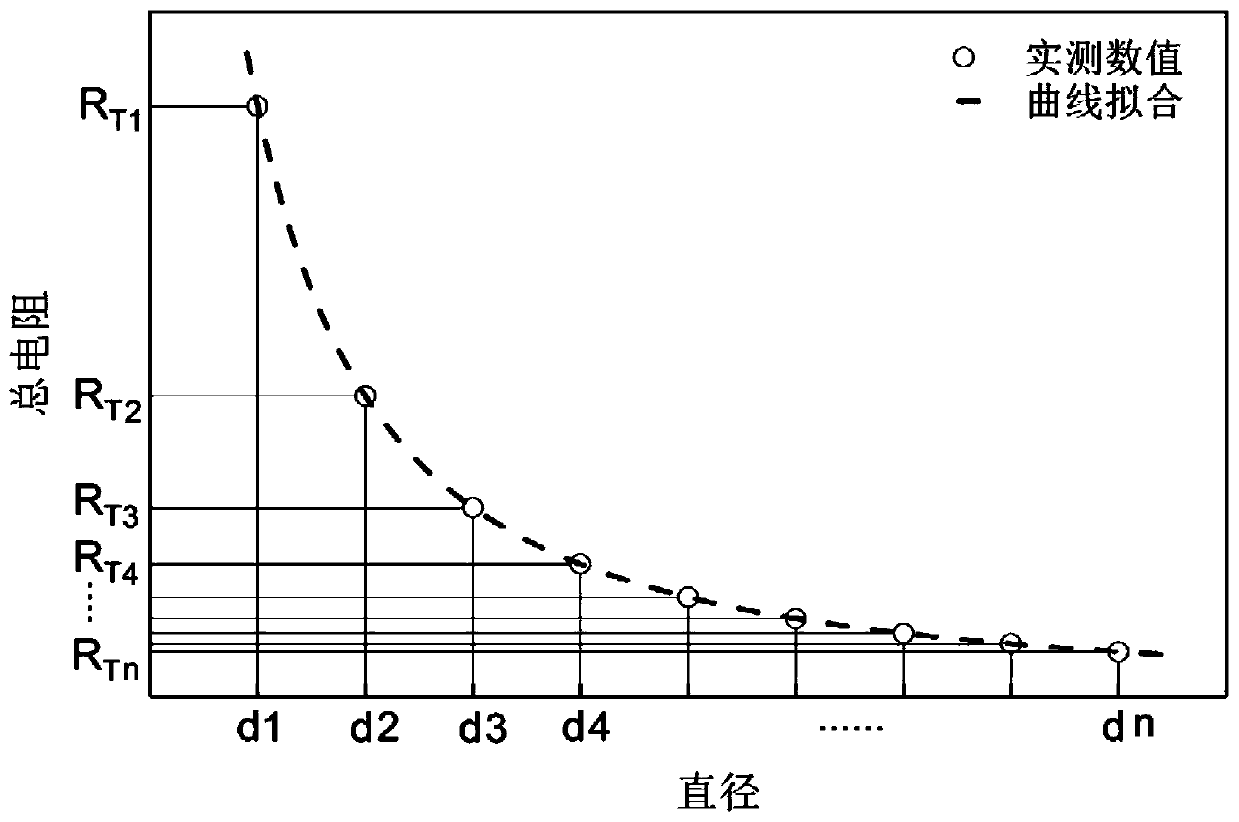

[0050] (2), test the inner diameters corresponding to the circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com