Multi-layer thermal insulation element for batteries

A multi-layer thermal insulation and component technology, applied in the direction of electrical components, battery pack components, battery isolation from its environment, etc., can solve the problems of easy rupture of thermal insulation components, damage to the surrounding environment, loss of thermal insulation function, etc., and achieve complete delay. Destruction or explosion, reducing the risk of explosion, simplifying the effect of thermal isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

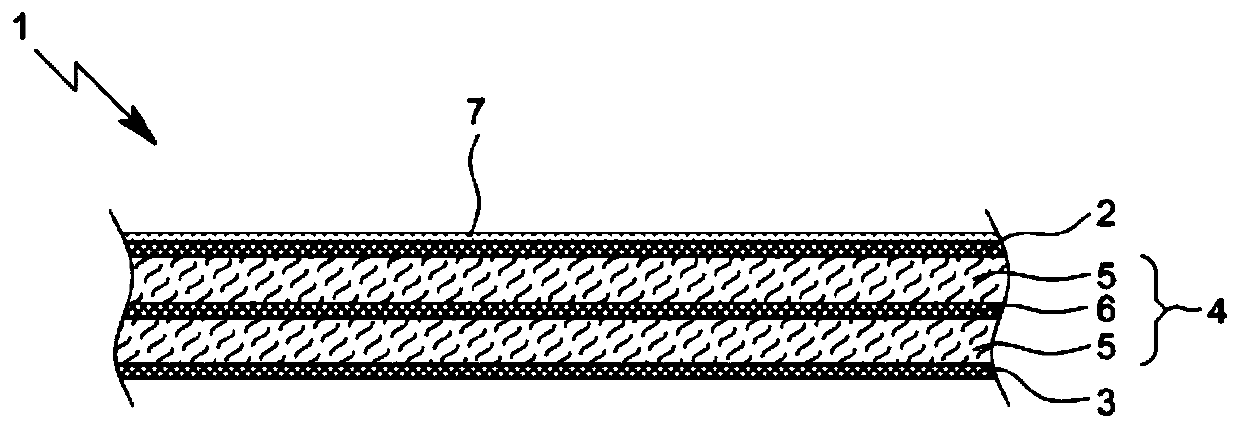

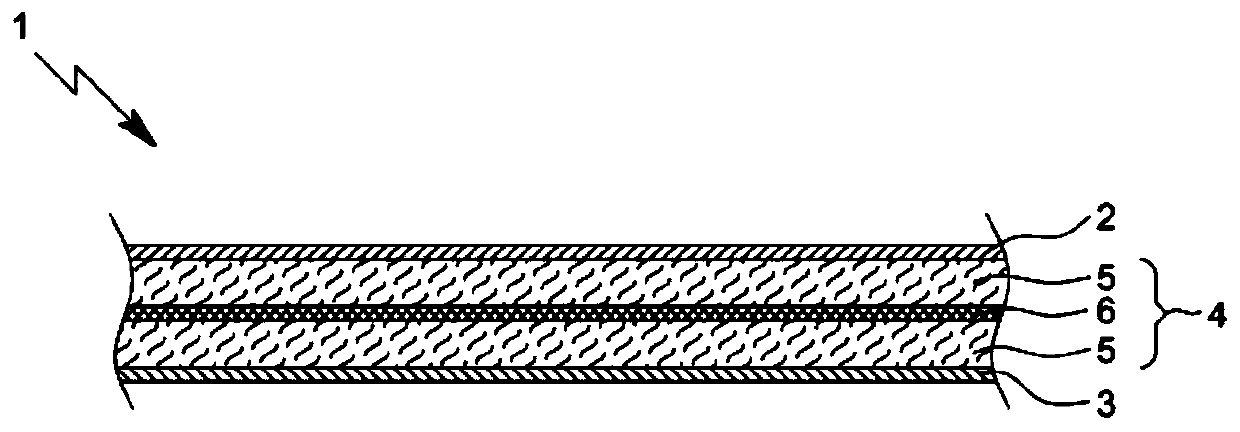

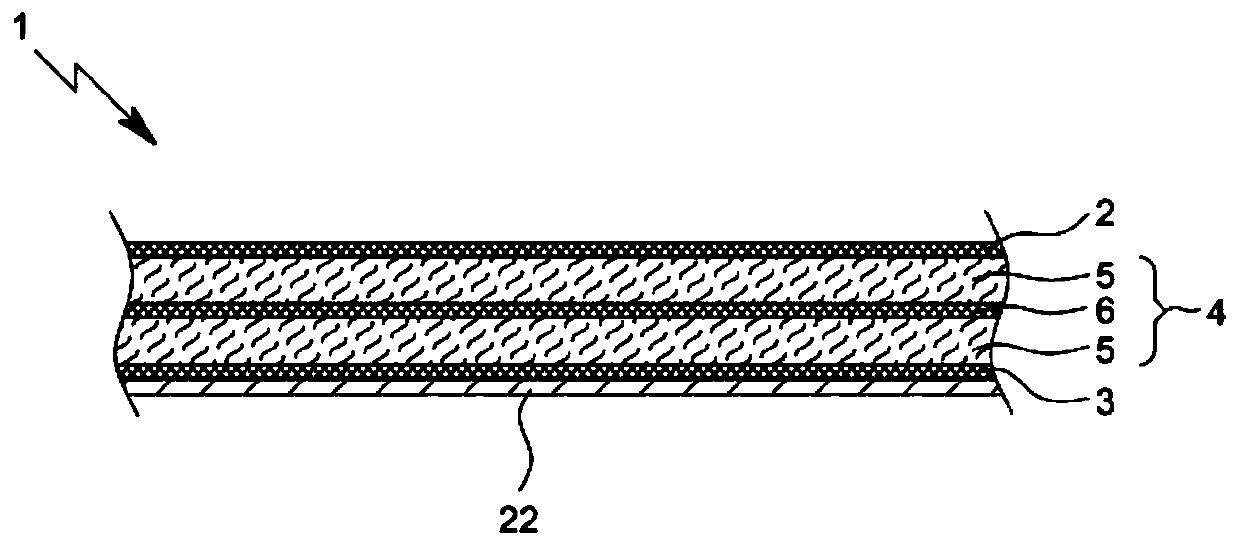

[0064] Figure 1A The proposed multilayer thermal insulation element 1 is shown in a schematic cross-sectional view not to scale. Figure 1B and Figure 1C A further embodiment of the proposed multilayer thermal insulation element 1 is shown in a schematic sectional illustration, also not to scale. The illustrated embodiments are similar to one another and can also be combined with one another as desired. in particular different Figure 1A , Figure 1B and Figure 1C Used only to highlight different preferred aspects.

[0065] The thermal insulation element 1 is especially designed as a flat stack.

[0066] The insulating element 1 is in particular compressible and at the same time bendable.

[0067] The term "bendable" is preferably understood to mean that the bending stiffness of the insulating element 1 is sufficiently low, where bending stiffness is a measure of the force acting against bending deformation of the component or of the insulating element 1 . Bending sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com