Unfired fly ash ceramsite concrete pot structure

A technology of fly ash ceramsite and concrete, applied in cultivation, container cultivation, ceramic products, etc., can solve the problems of easy withering of plants, poor air permeability of concrete potted plants, easy rot of potted plants, etc., and achieve the effect of enhancing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

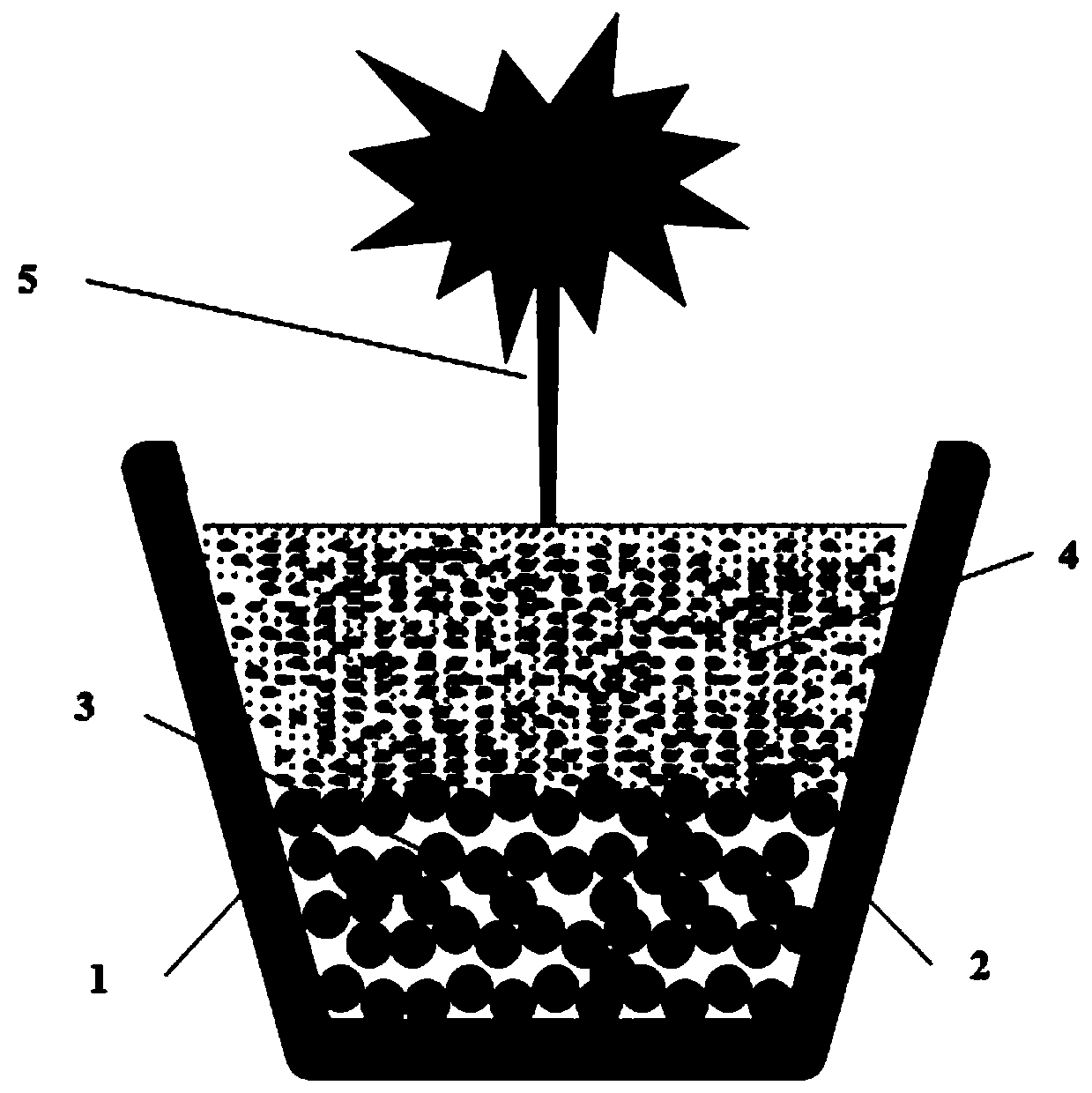

[0076] Combine below figure 1 To illustrate this embodiment, the present invention relates to the field of potted planting, more specifically, a potted plant structure with unburned fly ash ceramsite, including: a prefabricated unburned fly ash ceramsite concrete pot body 1, a silane-impregnated waterproof coating layer 2 , water storage breathable layer 3, cultivation layer 4 and green plant 5.

[0077] The prefabricated non-burning fly ash ceramsite concrete basin body 1 is the outermost layer, the silane impregnated waterproof coating layer 2 is set on the inner side of the prefabricated non-burning fly ash ceramsite concrete basin body 1, and the water storage and ventilation layer 3 is set on the prefabricated non-burning fly ash ceramsite concrete basin body 1. At the bottom of the inner cavity of the burnt fly ash ceramsite concrete basin body 1, the cultivation layer 4 is arranged above the water storage and air-permeable layer 3 in the inner cavity of the prefabricate...

Embodiment 2

[0082] Combine below figure 1 Describe this embodiment. This embodiment will further explain Embodiment 1. The prefabricated unfired fly ash ceramsite concrete basin body 1 is prefabricated by the factory, with a porosity of 5%. After the prefabrication is completed, the surface is continuously sprayed with a sealing spray gun The silane-impregnated waterproof coating is until the substrate is completely penetrated, and the silane-impregnated waterproof coating layer 2 is constructed by curing at 20°C for 36 hours, which can realize the breathability and impermeability of the basin body.

[0083] The cultivation layer 4 is composed of 30 parts of unfired pottery sand with a diameter of 5mm, 50 parts of power plant class II fly ash, and 20 parts of slag. Since the cultivation layer 4 contains more mineral components, and is loose, breathable and water-retaining, it can be used for planting greenery. The growth of plant 55 provided strong support.

[0084] The water-storage and...

Embodiment 3

[0086] Combine below figure 1 Describe this embodiment. This embodiment will further illustrate Embodiment 1. The prefabricated unfired fly ash ceramsite concrete basin 11 is prefabricated in a factory, with a porosity of 15%. After the prefabrication is completed, roll-coat silane on its surface The waterproof coating is until the substrate is thoroughly penetrated, and then cured at 30°C for 30 hours to construct the silane-impregnated waterproof coating layer 2, which can realize the breathability and impermeability of the basin body.

[0087] The cultivation layer 4 is composed of 50 parts of non-fired pottery sand with a diameter of 5mm, 30 parts of power plant class II fly ash, and 20 parts of slag. Since the cultivation layer 4 contains more mineral components, and is loose, breathable and water-retaining, it can be used for planting greenery. Provide strong support for the growth of plant 5.

[0088] The water-storage and air-permeable layer 3 is made of non-burning f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com