A stepwise hot stamping forming method for ultra-high-strength steel plates

A hot stamping forming, ultra-high strength technology, applied in the field of hot stamping process, can solve the problems of inability to precisely control the springback of ultra-high strength steel plates, high energy consumption and low production efficiency of the hot stamping process, saving energy consumption, The effect of high water cooling efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

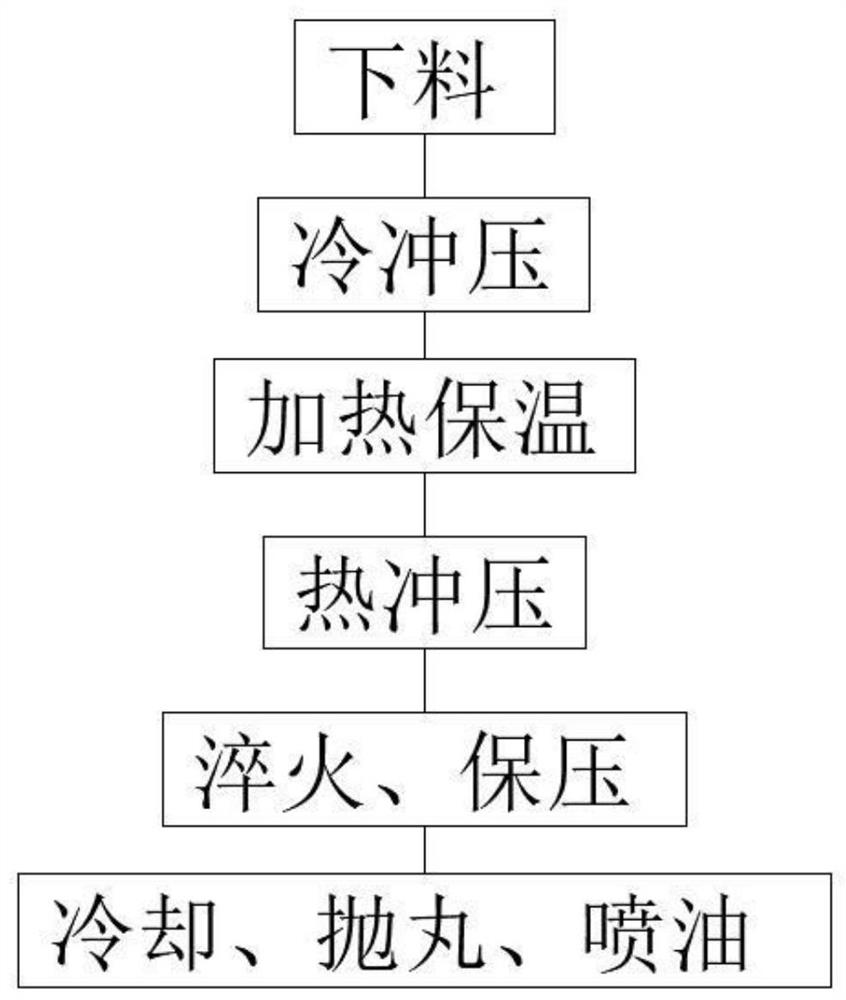

[0032] The cascade hot stamping forming technology is a new material forming process that combines cold stamping and hot stamping, and is one of the most reliable process solutions to achieve lightweight bodywork. Combining cold stamping and hot stamping can complete the full coverage of the body with ultra-high-strength steel. see figure 1 , a stepwise hot stamping method for ultra-high-strength steel plates, comprising the following steps:

[0033] Step 1: Cutting

[0034] The base material is 22MnB5, 27MnCrB5 or 37MnB4, and the size of the ultra-high-strength steel sheet is determined according to the performance requirements and geometric parameters of the formed part. The base material of this embodiment is preferably 22MnB5.

[0035] Step 2: Cold Stamping

[0036] Under normal temperature conditions, the cold stamping forming process of ultra-high-strength steel sheets is completed to obtain preformed parts. Due to the particularity of the cascade hot stamping formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com