Baffle structure of conveying chain of plate shearing machine and mounting method of baffle structure

A technology of baffle structure and installation method, which is applied to shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve problems such as broken thread teeth on the baffle side of fixing screws, hidden dangers of unsafety, and broken transport chains, etc. To achieve the effect of reducing transport chain breaks, reducing processing failures and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

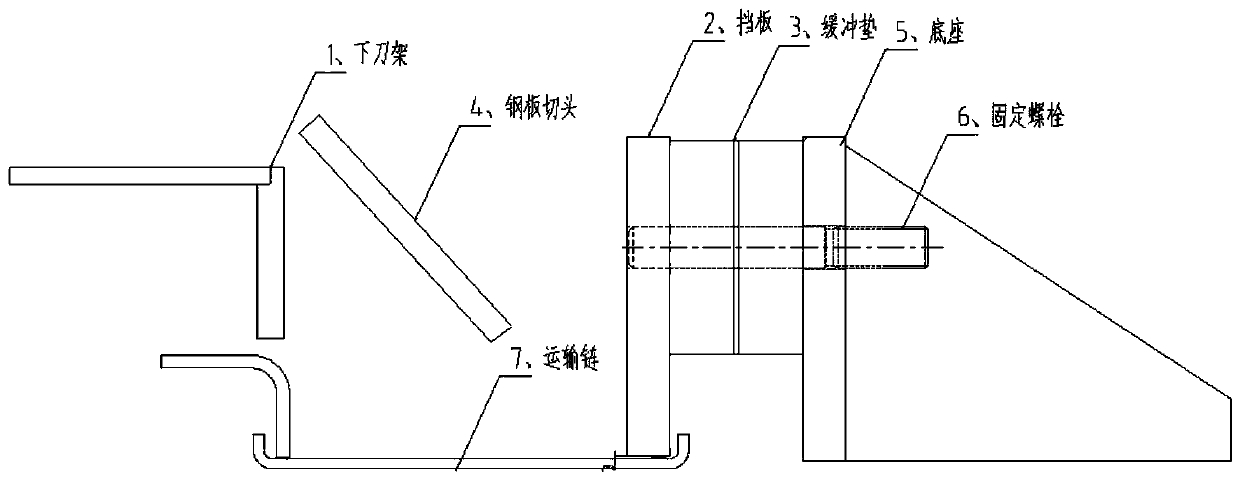

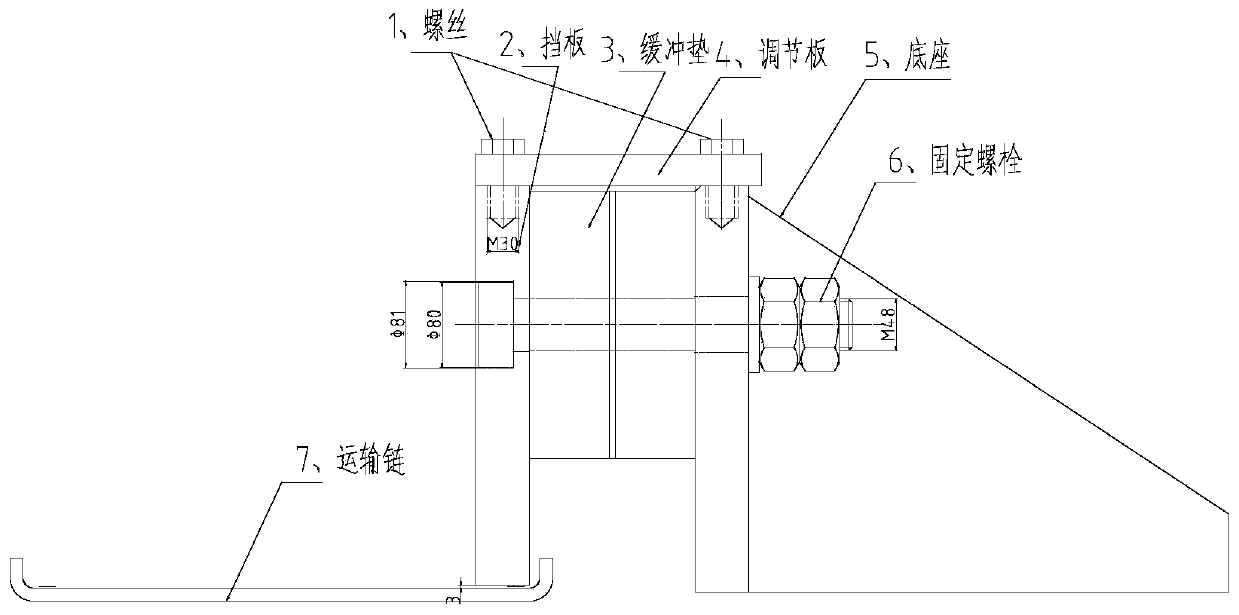

[0014] Such as figure 2 As shown, the baffle structure of the shearing machine transport chain mainly involves the improvement of two aspects:

[0015] 1. Improve the fixing bolt of the baffle: from the original double-headed bolt to a single-headed bolt with a step, this bolt has a circular step of φ80mm and 33mm long at one end, which can ensure that the bolt will not break and will not run towards the nut. , to ensure that the baffle is not loose.

[0016] 2. Add an adjustment plate that can adjust the height of the baffle: Drill holes on the top of the baffle and the base and tap the M30 screw 1, and connect the baffle 2 with the base 5 through the screw 1 and the adjustment plate 4, and pass through the adjustment plate Increase or decrease the spacer at the bottom (it is a hard spacer, aluminum and other metal sheets can be used,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com