High-bending-resistance cement-based material and preparation method thereof

A cement-based material, high flexural resistance technology, applied in the field of concrete, can solve the problems of reducing the compressive strength of cement matrix, reducing the compressive strength of cement-based materials, poor flexural and tensile properties, etc., to avoid polymerization, reduce The effect of slippage and improvement of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

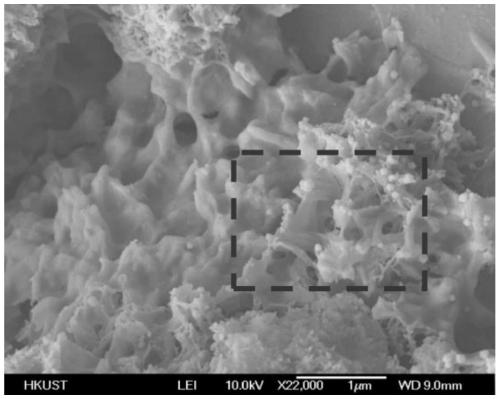

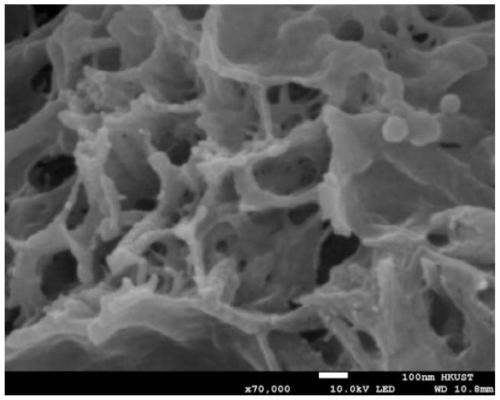

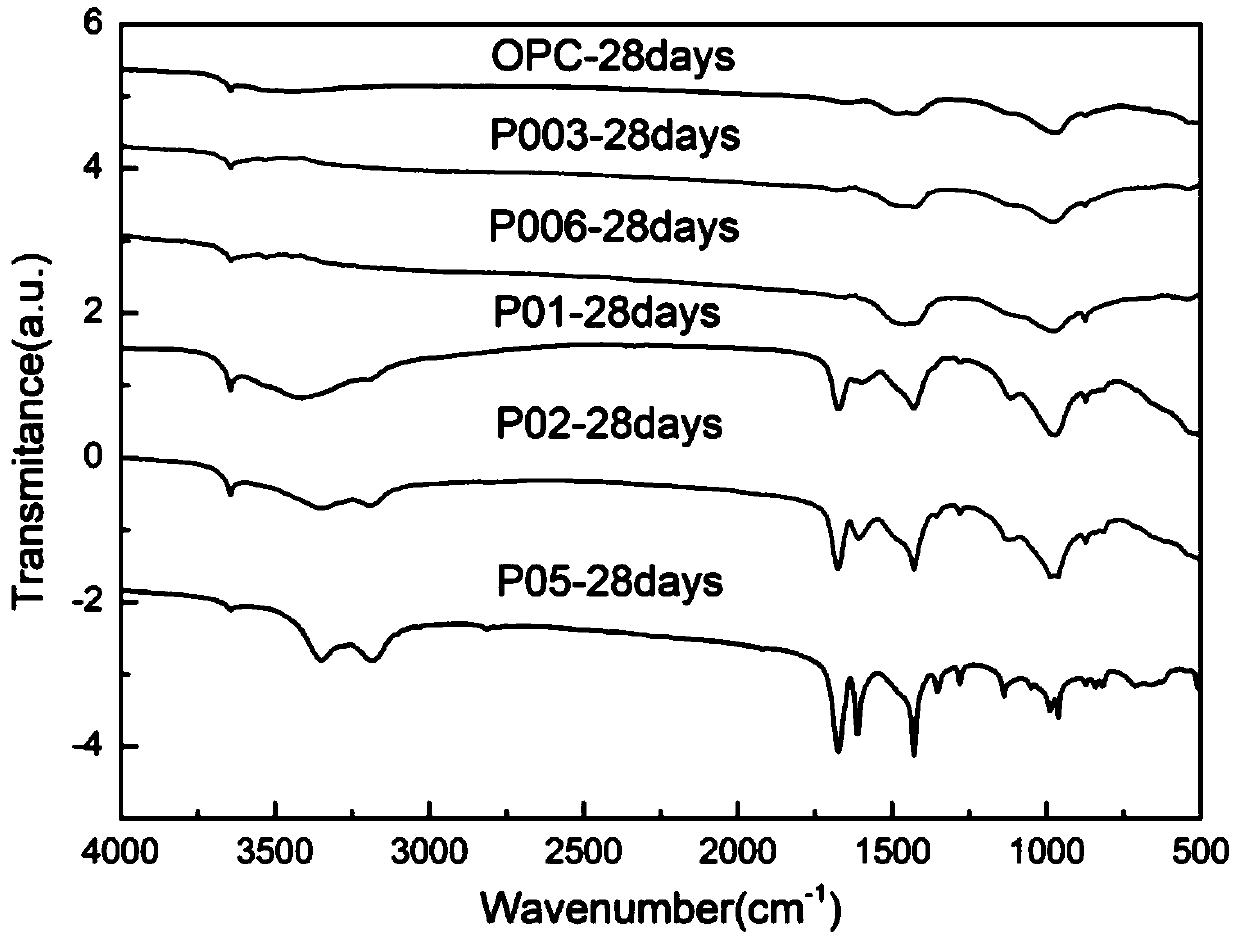

Image

Examples

preparation example Construction

[0028] It should be noted that this preparation method can make the prepared high molecular polymer and cement hydrate chemically bonded, so that the polymer does not exist as a separate polymer phase in the cement hydrate, basically avoiding the The polymerization of polymers, while reducing the slippage between polymer chains, effectively improves the flexural strength of cement-based materials. Specifically include the following steps:

[0029] S1, preparation of reaction solution

[0030] The polymerization monomer, initiator and accelerator are mixed and dissolved in water to obtain a reaction solution, and the reaction chemical raw materials are dissolved and mixed first, so that they can be mixed more uniformly when subsequently mixed with cement.

[0031] Preferably, the mass ratio of polymerized monomer to cement is 0.5-7:100; the mass ratio of initiator to polymerized monomer is 0.3-0.6:100; the mass ratio of accelerator to polymerized monomer is 0.001-0.018:100. T...

Embodiment 1

[0047] This embodiment provides a method for preparing a high-bending cement-based material, comprising the following steps:

[0048]At 20°C, add 0.3g of acrylamide (AM) into water, stir until the acrylamide is completely dissolved, then add 0.0009g of ammonium persulfate and 0.000003g of N,N,N',N'-tetramethyl-ethanedi amine, and stirred at room temperature for 10 minutes to obtain a transparent aqueous solution of acrylamide with a mass fraction of 0.3%.

[0049] Under the condition of 20° C., the prepared acrylamide solution was mixed with 60 g of cement, and stirred for 3 minutes. Then pour the acrylamide-cement slurry that has been stirred into a mold for molding, remove the formwork for 24 hours, and then cure for 7 days and 28 days to obtain a high-bending cement paste (water-cement ratio of 0.4).

Embodiment 2-5

[0051] This example provides a method for preparing a high-bending cement-based material. The specific steps are roughly the same as in Example 1, except that in Examples 2-5, the mass fractions of acrylamide aqueous solution are 0.6%, 1%, 2%, 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com