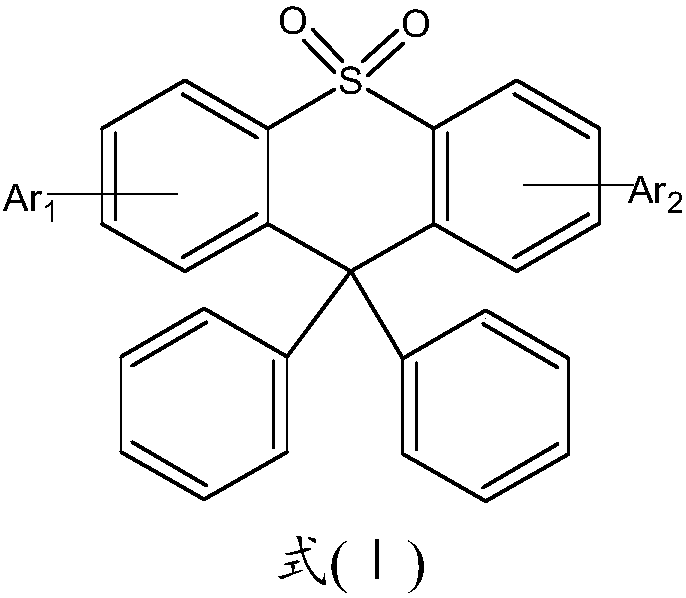

Thiaxanthene dioxide type organic electroluminescence material and preparation method and application thereof

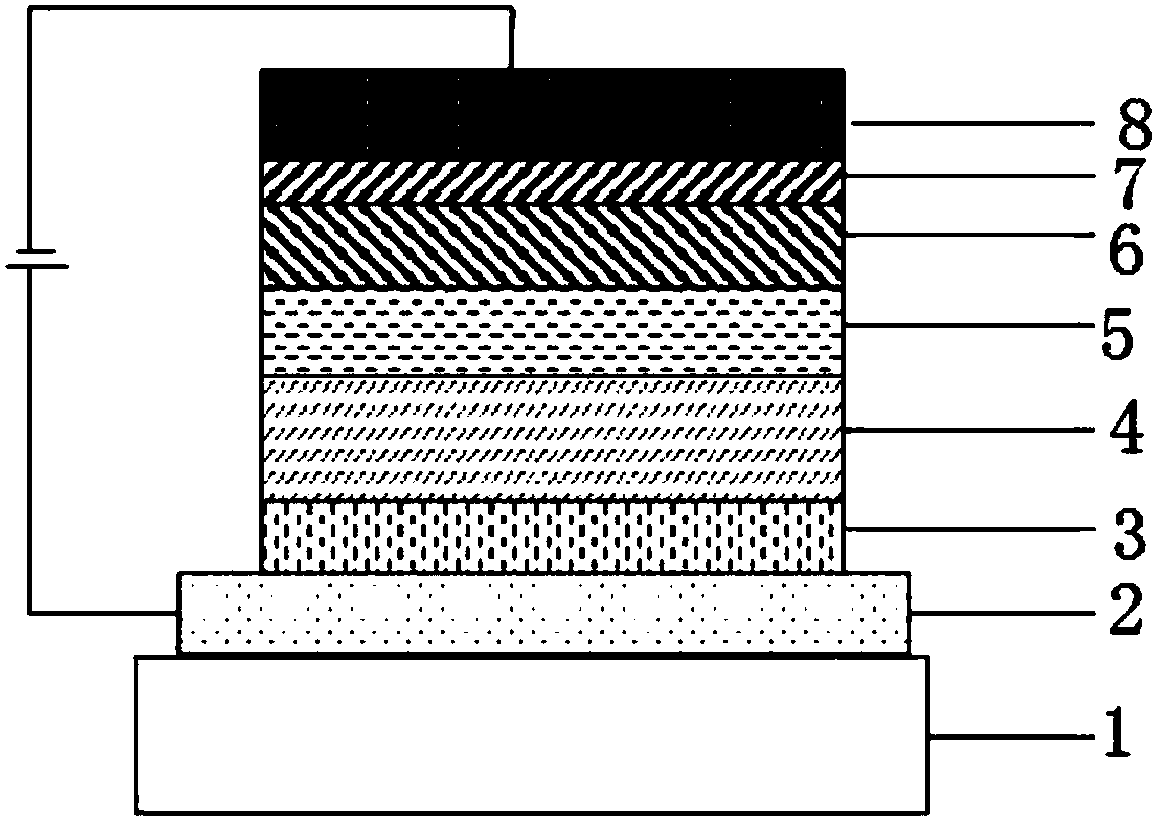

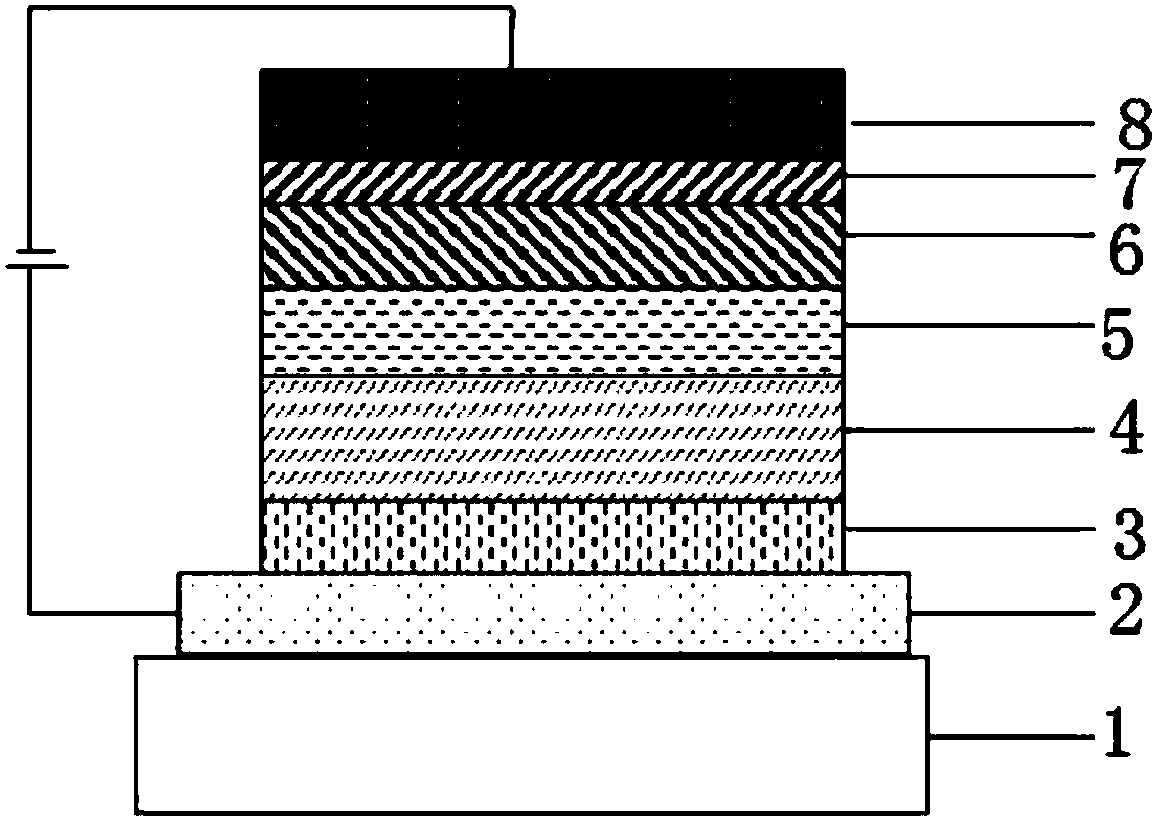

A technology of thiadioxide and luminescence, which is applied in the direction of luminescent materials, chemical instruments and methods, organic chemistry, etc., to achieve the effects of improving efficiency roll-off, reducing efficiency roll-off, and reducing device voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Compound A1

[0048]

[0049] In a 250ml three-neck flask, under a nitrogen atmosphere, add 0.01mol 9,9-diphenyl-3-bromo-10,10-thioxanthene dioxide, 0.011mol compound C1, 0.03mol sodium tert-butoxide, 1× 10-4mol Pd 2 (dba) 3 , 1×10-4mol tri-tert-butylphosphine, 150ml toluene, heated and refluxed for 24 hours, sampled and spotted, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 98.56% and a yield of 54%.

[0050] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 46 h 33 NSO 3 , theoretical value: 679.22, test value: 679.43.

Embodiment 2

[0051] Example 2 Compound A2

[0052]

[0053] In a 250ml three-neck flask, under a nitrogen atmosphere, add 0.01mol 9,9-diphenyl-3-bromo-10,10-thioxanthene dioxide, 0.011mol compound C2, 0.03mol sodium tert-butoxide, 1× 10-4mol Pd 2 (dba) 3 , 1×10-4mol tri-tert-butylphosphine, 150ml toluene, heated and refluxed for 24 hours, sampled and spotted, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 99.70% and a yield of 59%.

[0054] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 46 h 33 NO 3 S, theoretical value: 679.22, test value: 679.58.

Embodiment 3

[0055] Example 3 Compound A3

[0056]

[0057] In a 250ml three-neck flask, under a nitrogen atmosphere, add 0.01mol 9,9-diphenyl-3-bromo-10,10-thioxanthene dioxide, 0.011mol compound C3, 0.03mol sodium tert-butoxide, 1× 10-4mol Pd 2 (dba) 3 , 1×10-4mol tri-tert-butylphosphine, 150ml toluene, heated to reflux for 24 hours, sampled and spot plated, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 99.80% and a yield of 46%.

[0058] High resolution mass spectrometry, ESI source, positive ion mode, molecular formula C 46 h 33 NO 3 S, theoretical value: 679.22, test value: 679.36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com