Preparation method of polypeptide-chitosan composite nanoparticles loaded with coenzyme Q10

A technology of composite nanoparticles and chitosan, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of singleness, easy aggregation, poor stability, etc., and avoid aggregation phenomenon, good biocompatibility and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

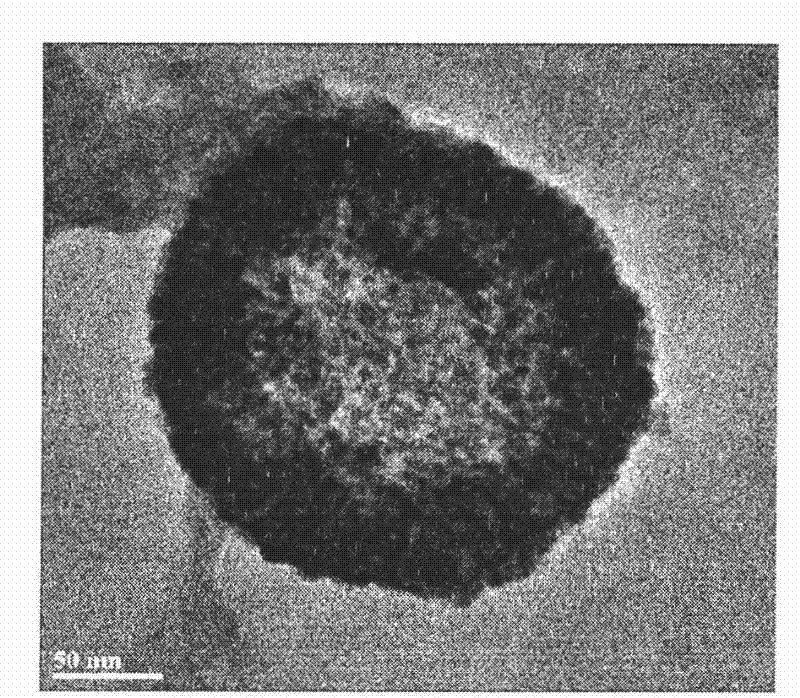

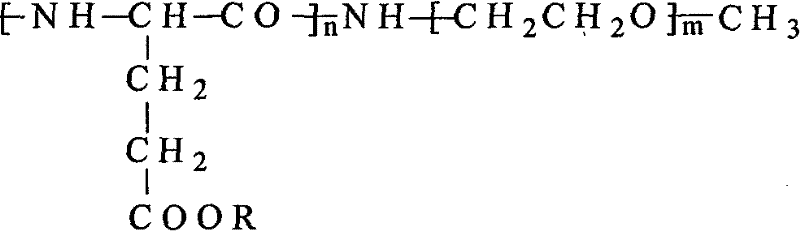

[0032] Dissolve 2.5 mg of PBLG-b-PEG block copolymer and 3 mg of coenzyme Q10 mixture in 25 mL of dimethylformamide (DMF) / tetrahydrofuran (THF) mixed solvent at room temperature, put it into a dialysis bag after completely dissolving, and Dialyze in deionized water for 72 hours, and replace with fresh deionized water every 3 hours to remove organic solvents. After dialysis in deionized water, the unembedded drug was removed by centrifugation, and the supernatant was filtered with a filter membrane with a diameter of 0.45 μm to obtain a drug-loaded micellar solution.

[0033] Measure 20mL of the coenzyme Q10-polypeptide self-assembly nano solution that has been prepared, add acetic acid to make the concentration of acetic acid 1.5mg / mL, and dissolve 15mg of chitosan in 10mL of acetic acid solution of the same concentration, and wait for chitosan After the sugar is completely dissolved, mix and stir the acetic acid solution of coenzyme Q10-polypeptide and chitosan, and add 30 mL...

Embodiment 2

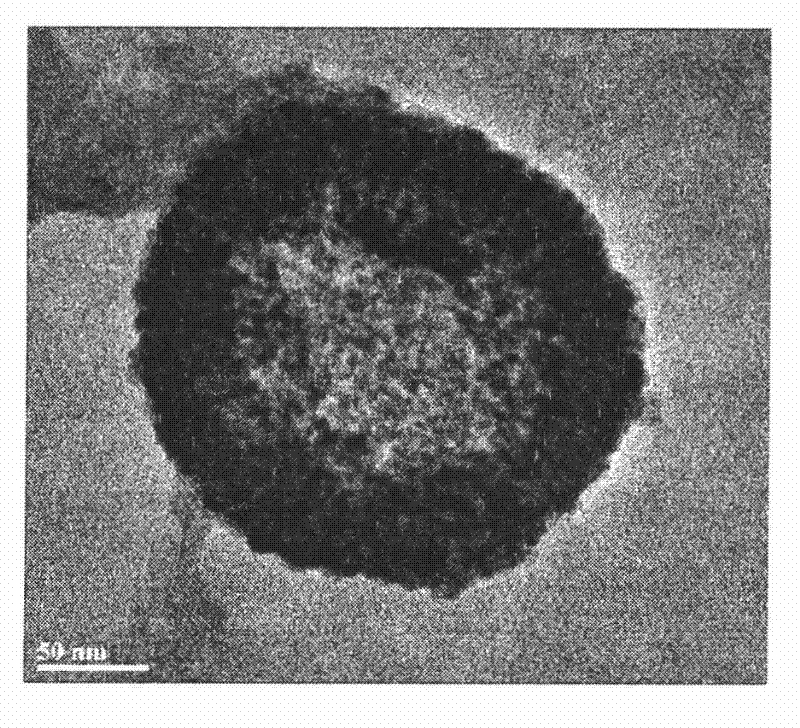

[0035] Dissolve 2.5 mg of PBLG-b-PEG block copolymer and 8 mg of coenzyme Q10 mixture in 25 mL of dimethylformamide (DMF) / tetrahydrofuran (THF) mixed solvent at room temperature. Dialyze in deionized water for 72 hours, and replace with fresh deionized water every 3 hours to remove organic solvents. After dialysis in deionized water, the unembedded drug was removed by centrifugation, and the supernatant was filtered with a filter membrane with a diameter of 0.45 μm to obtain a drug-loaded micellar solution.

[0036]Measure 20mL of the coenzyme Q10-polypeptide self-assembled nano solution that has been prepared, add acetic acid to make the concentration of acetic acid 1.5mg / mL, and dissolve 30mg of chitosan in 10mL of acetic acid solution of the same concentration. After the sugar is completely dissolved, mix and stir the acetic acid solution of coenzyme Q10-polypeptide and chitosan, and add 30 mL of sodium tripolyphosphate (TPP) solution with a concentration of 1.5 mg / mL dropw...

Embodiment 3

[0038] Dissolve 2.5 mg of PBLG-b-PEG block copolymer and 2.5 mg of coenzyme Q10 mixture in 25 mL of dimethylformamide (DMF) / tetrahydrofuran (THF) mixed solvent at room temperature, put it into a dialysis bag after completely dissolving, Dialyze in deionized water for 72 hours, and replace with fresh deionized water every 3 hours to remove organic solvents. After dialysis in deionized water, the unembedded drug was removed by centrifugation, and the supernatant was filtered with a filter membrane with a diameter of 0.45 μm to obtain a drug-loaded micellar solution.

[0039] Measure 20mL of the coenzyme Q10-polypeptide self-assembled nano solution that has been prepared, add acetic acid to make the concentration of acetic acid 1.5mg / mL, and dissolve 30mg of chitosan in 10mL of acetic acid solution of the same concentration. After the sugar is completely dissolved, mix and stir the acetic acid solution of coenzyme Q10-polypeptide and chitosan, and add 30 mL of sodium tripolyphosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com