Microwave dielectric ceramic powder and preparation method thereof, microwave dielectric ceramic and microwave component

A technology for microwave dielectric ceramics and components is applied in the field of ceramic powder, which can solve the problems of inability to meet the use requirements and low ceramic quality factor values, and achieve the effects of poor comprehensive performance and high physical and electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

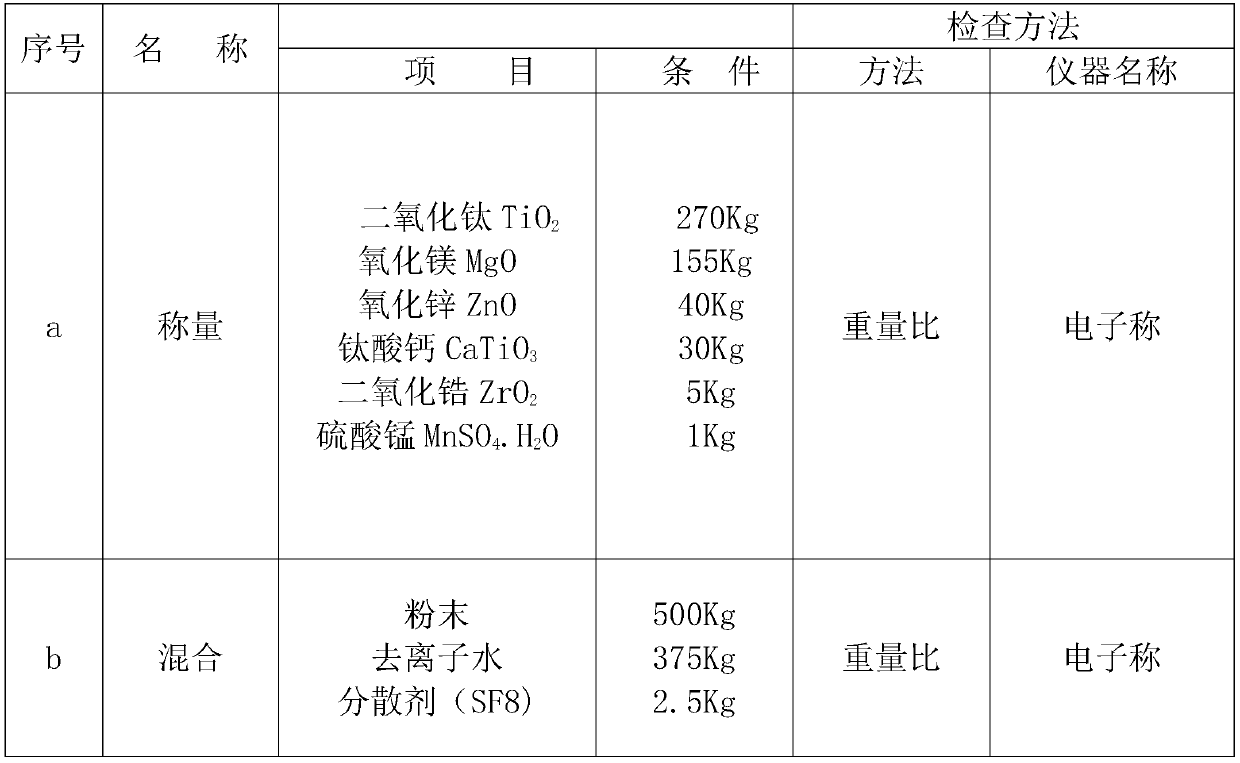

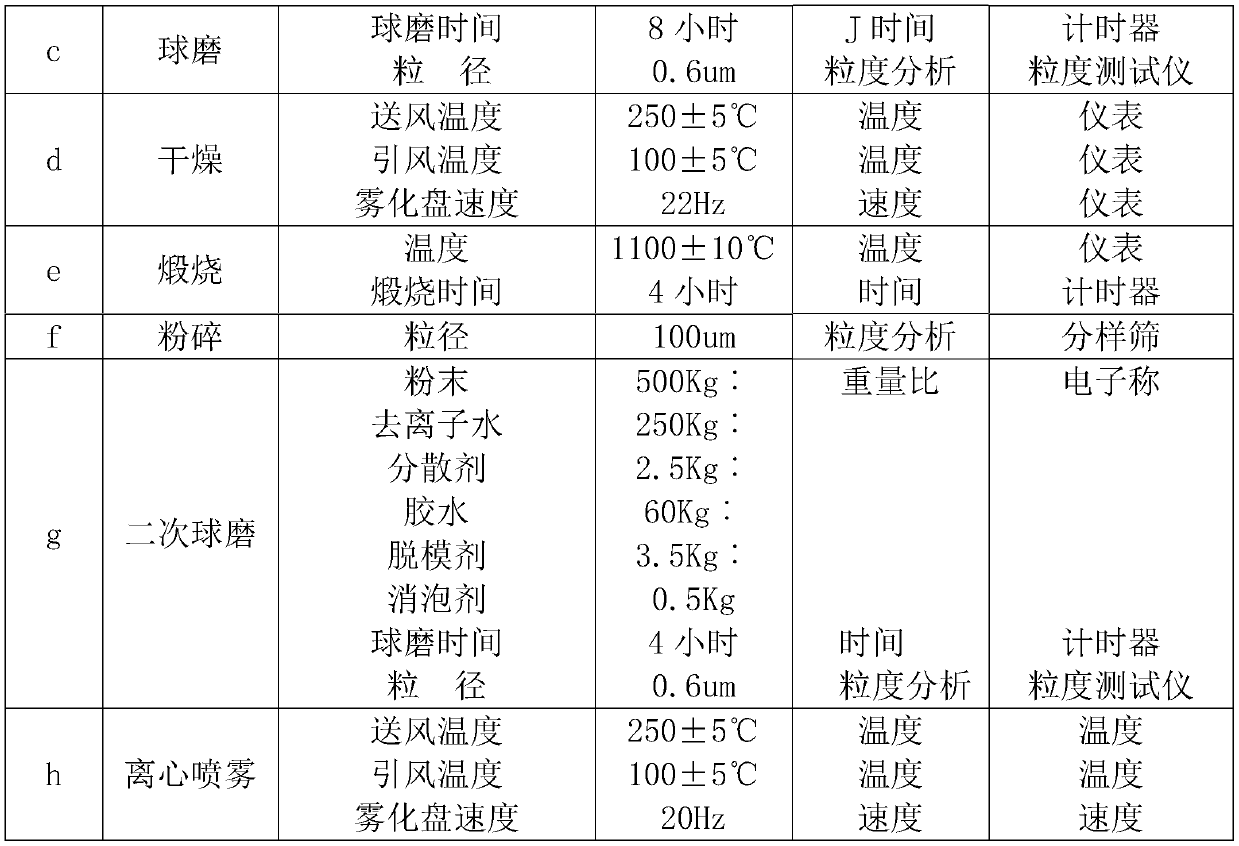

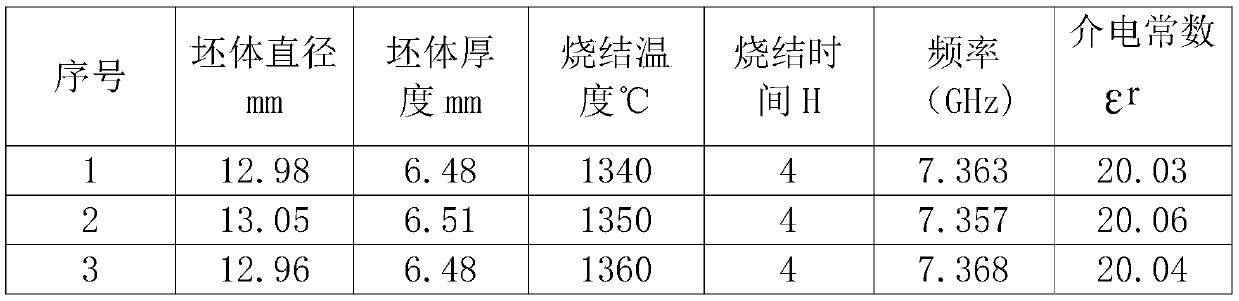

[0026] The invention discloses a microwave dielectric ceramic powder, which is a microwave dielectric ceramic powder with a dielectric constant of 20 and a ceramic quality factor value of more than 80,000. The microwave dielectric ceramic powder includes powder, and the powder includes a weight ratio of 270 : 155: 40: 30: 5 titanium dioxide (TiO 2 ), magnesium oxide (MgO), zinc oxide (ZnO), calcium titanate (CaTiO 3 ), zirconium dioxide (ZrO 2 ) and trace additive manganese sulfate MnSO 4 .H 2 O; Wherein, the microwave medium ceramic powder also includes deionized water, dispersant, glue, release agent, defoamer during centrifugal spraying; the powder, deionized water, dispersant, glue, release agent, defoamer The weight ratio of the agent is 500: 375: 2.5: 60: 3.5: 0.5. Of course, the present invention can also appropriately add additives that do not change the performance of each component, such as pigments and the like.

[0027] In this embodiment, the deionized water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap