Pre-removal system and method for removing impurities before raw cotton processing

A raw cotton and cotton feeding technology, which is applied in the field of pre-impurity removal system, can solve the problems of blurred information, decreased resolution, and reduced detection accuracy of captured pictures by cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

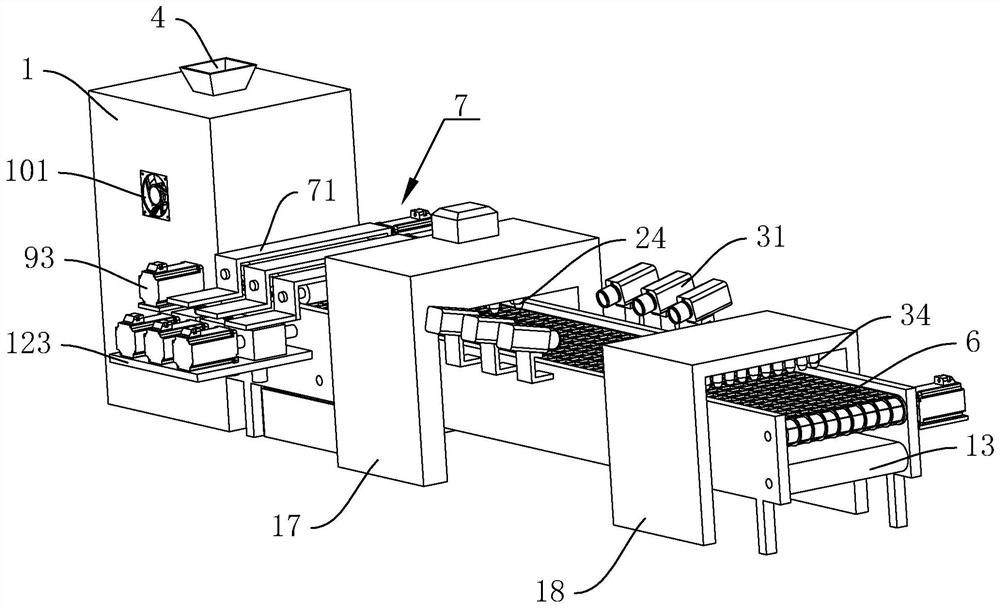

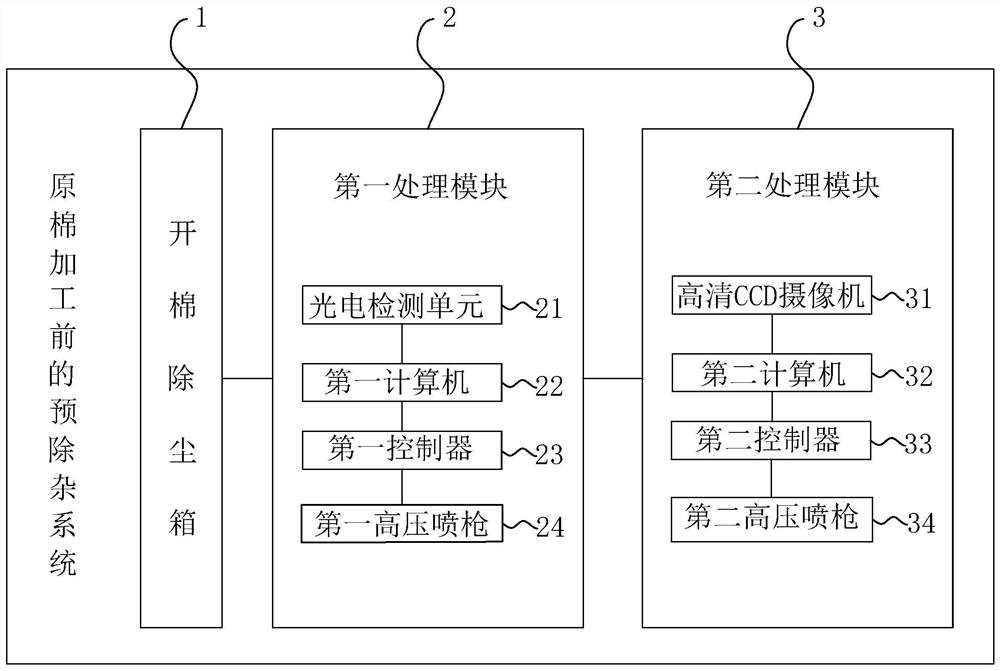

[0052] refer to figure 1 and figure 2 , is a pre-impurity removal system for raw cotton before processing disclosed in the present invention, which includes a cotton opening dust removal box 1, a first processing module 2 and a second processing module 3 arranged in sequence.

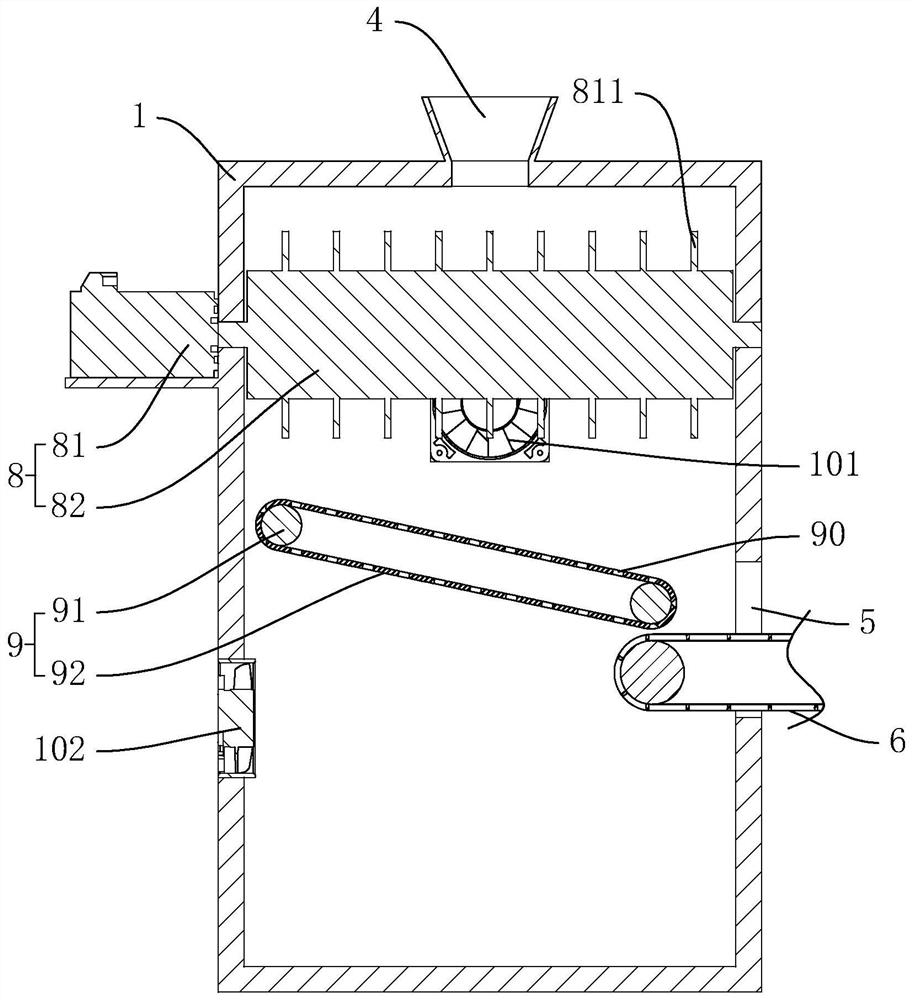

[0053] refer to figure 1 , the cross-section of the cotton-opening dust removal box 1 is rectangular, and the top surface of the cotton-opening dust removal box 1 is provided with a raw cotton inlet 4, combined with image 3 , the side of the cotton opening dust removal box 1 is provided with a rectangular pure cotton outlet 5, and the pure cotton outlet 5 is provided with a cotton feeding conveyor belt 6, and the cotton feeding conveyor belt 6 is set in a grid shape, and the cotton feeding conveyor belt 6 is close to the cotton opening and dust removal One end of case 1 stretches in the cotton opening dust removal case 1.

[0054] refer to image 3 The cotton opening and dust removal box 1 is prov...

Embodiment 2

[0067] refer to Figure 7 , a method for pre-removing impurities before raw cotton processing based on embodiment one, comprising the following steps:

[0068] S100. The raw cotton passes through the cotton opening dust removal box 1 to remove dust and other small impurities in the raw cotton; specifically, the raw cotton enters the cotton opening dust removal box 1 through the raw cotton inlet 4, and the cotton opening motor 82 is started to drive the cotton opening roller 81 to rotate to disperse the raw cotton After opening, the raw cotton air supply assembly 101 supplies air to the cotton opening dust removal box 1, and the dust and impurities in the raw cotton are exposed, and the air exhaust assembly 102 performs air suction to give suction to the dust floating above the cotton conveyor belt 92. Impurities are absorbed from the dust hole 90, and the raw cotton is transported to the pure cotton outlet 5 through the cotton conveyor belt 92 and falls on the cotton conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com