Spliced heating house with hard structure

A hard structure, splicing technology, applied in the field of house heat preservation, can solve the problems of large deformation coefficient, poor airtight effect, and influence on indoor temperature, etc., achieve strong waterproof and corrosion resistance, improve heat preservation and air tightness, and enhance heat preservation function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

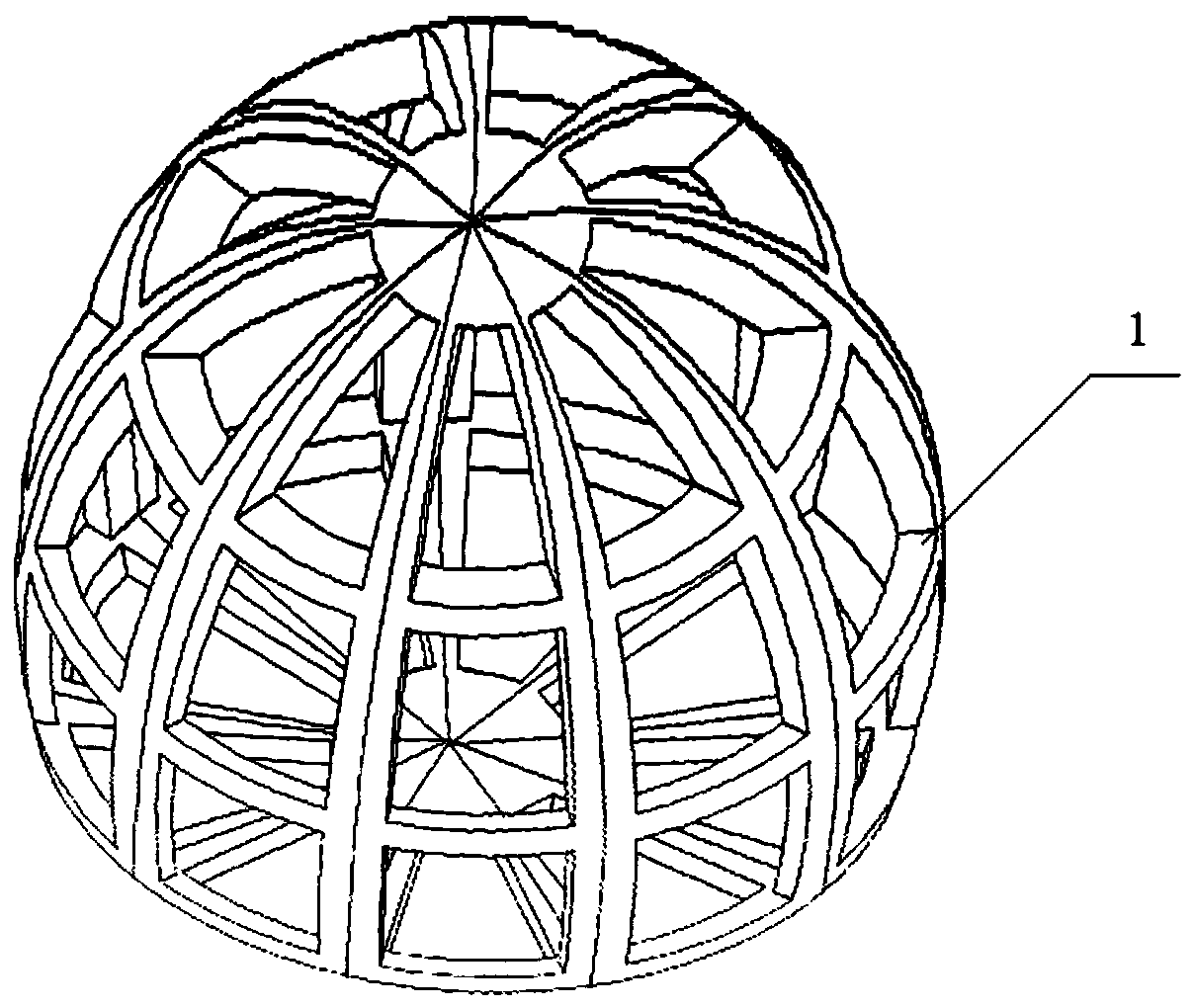

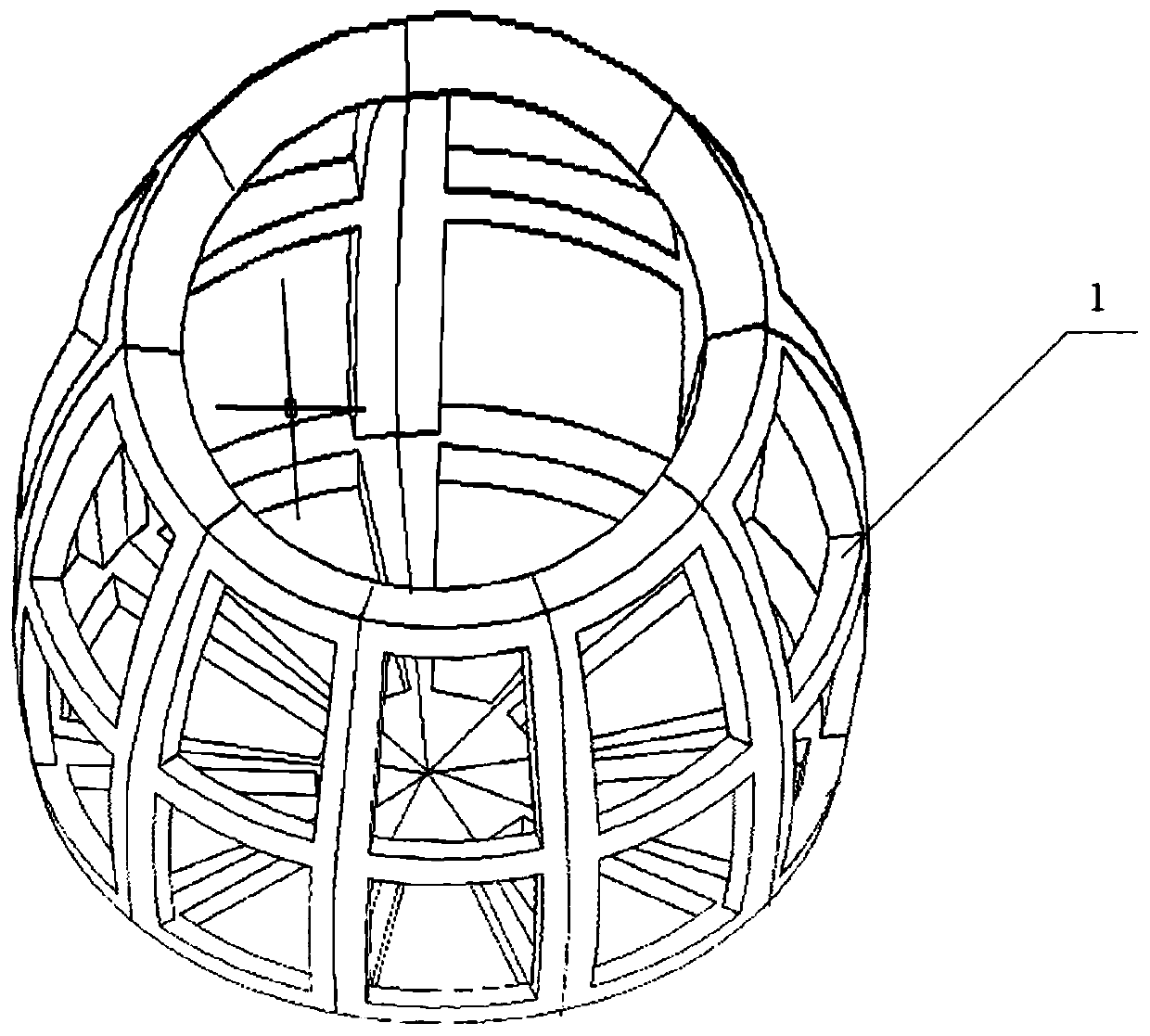

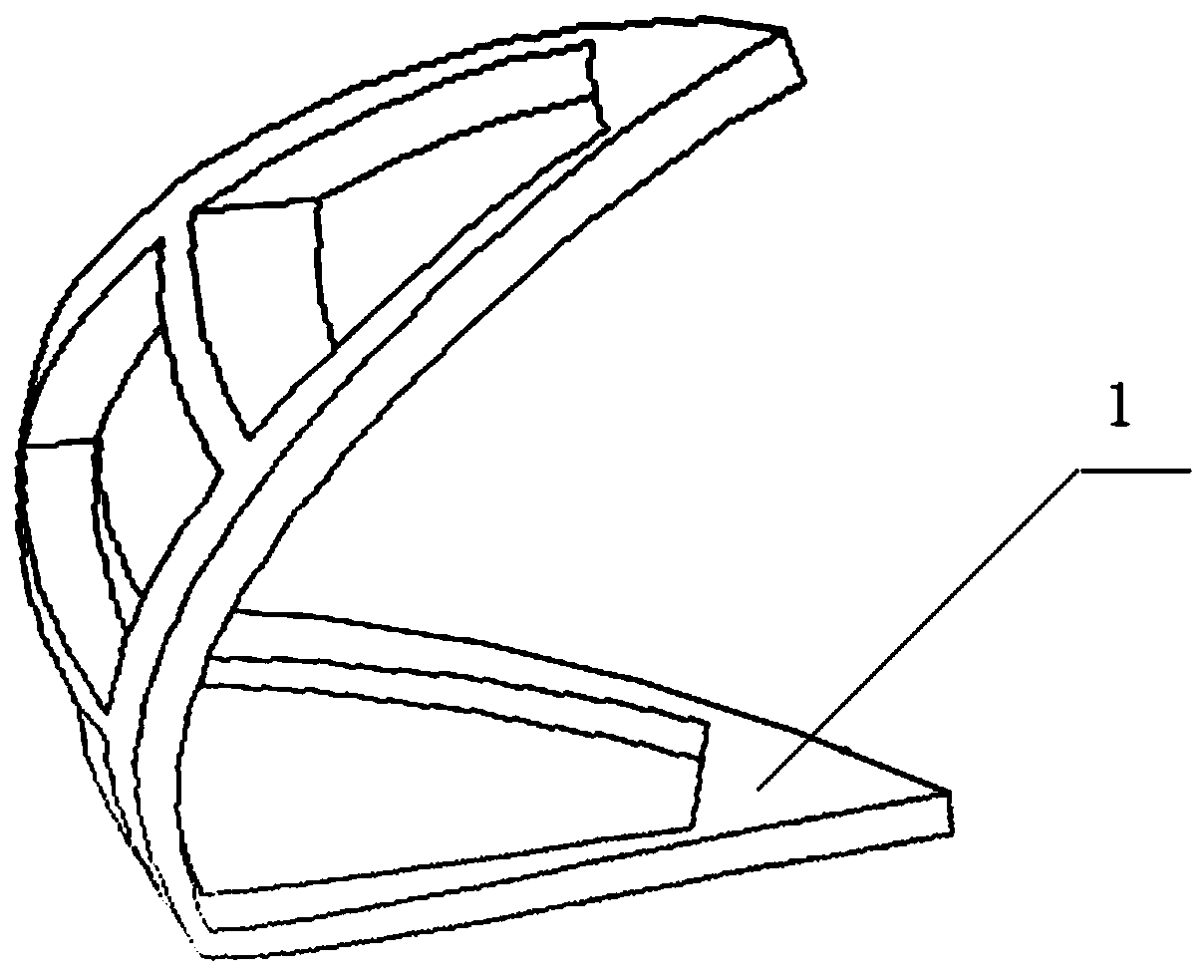

[0041] Specific implementation mode one: combine Figure 1-8 Describe this embodiment, a spliced heating room with a rigid structure, which includes multiple connecting parts 1 and walls 2, the multiple connecting parts 1 are assembled into a whole structure along the circumferential direction, and the setting of the wall 2 covering Outside the whole structure, the connection part 1 includes a bottom and a side part, and the bottom and side parts of every two adjacent connection parts 1 are arranged centripetally.

[0042] The connection part can use fiberglass material.

[0043] The hemispherical shape adopts about two-thirds of the spherical shape.

specific Embodiment approach 2

[0044] Specific implementation mode two: combination Figure 1-8 Describe this embodiment. The first difference between this embodiment and the specific embodiment is that the overall structure is hemispherical, and the top of each connecting part 1 is only connected to the top of two adjacent connecting parts 1, or each connecting part The top of 1 is connected with all connecting parts 1.

[0045] Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Specific implementation mode three: combination Figure 1-8 Describe this embodiment. The difference between this embodiment and the specific embodiment is that when the top end of each connecting part 1 is only connected to the top ends of two adjacent connecting parts 1, a top cover 3 is provided at the top of the entire structure. The cover 3 is connected with a plurality of connecting parts 1, and the top cover 3 is made of light-transmitting material or other lightweight materials.

[0047] Other compositions and connection methods are the same as those in Embodiment 1.

[0048] The top cover can be composed of sunlight board, glass, glass fiber reinforced plastic with high transparency or other transparent light materials. The purpose is to achieve the viewing effect of looking up at the sky and the night sky, and to build a sun cabin and a starry sky cabin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com