Advance guide pipe driving device for underground excavation trolley

A trolley and leading technology, applied in the direction of supporting devices, shaft equipment, shaft lining, etc., can solve the problems of high labor intensity, leading pipe bending, shallow penetration depth, etc., to facilitate installation and disassembly, and reduce labor Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0037] First of all, let me explain that the direction mentioned in the technical plan is in figure 1 The left side of the middle screen is the rear or rear end of each device, and the right side of the screen is the front or front end of each device, which facilitates a clear description of the technical solution.

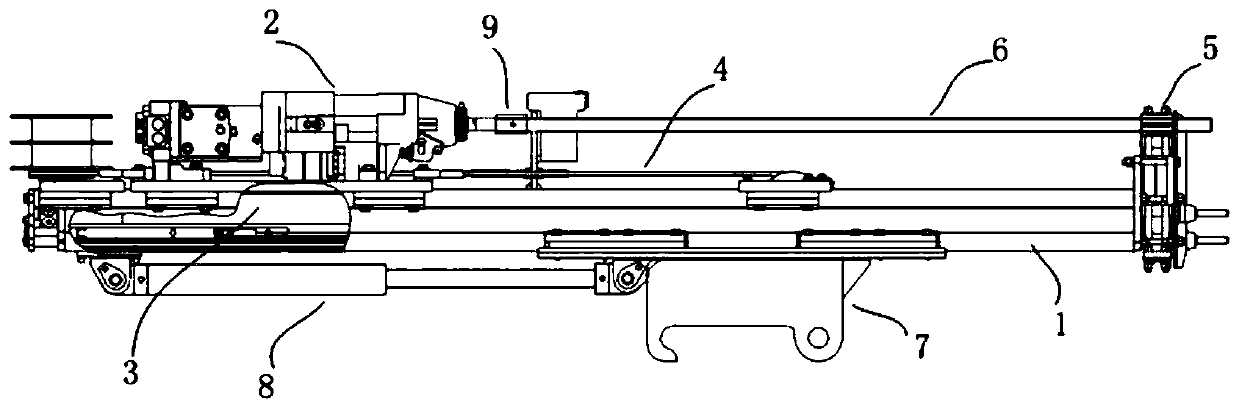

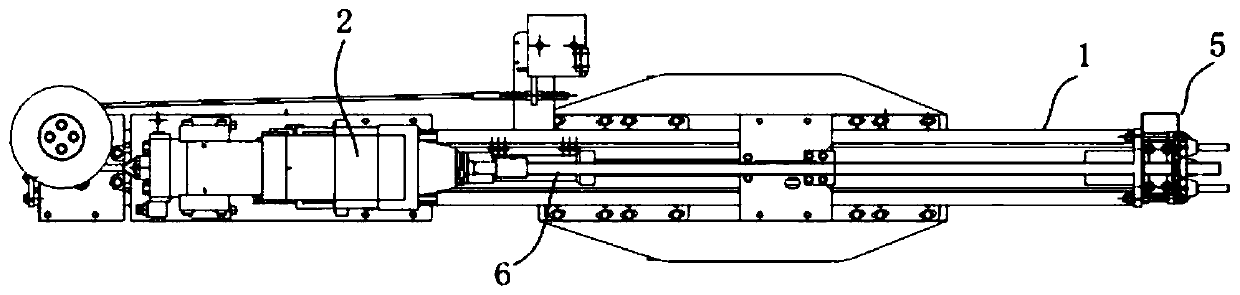

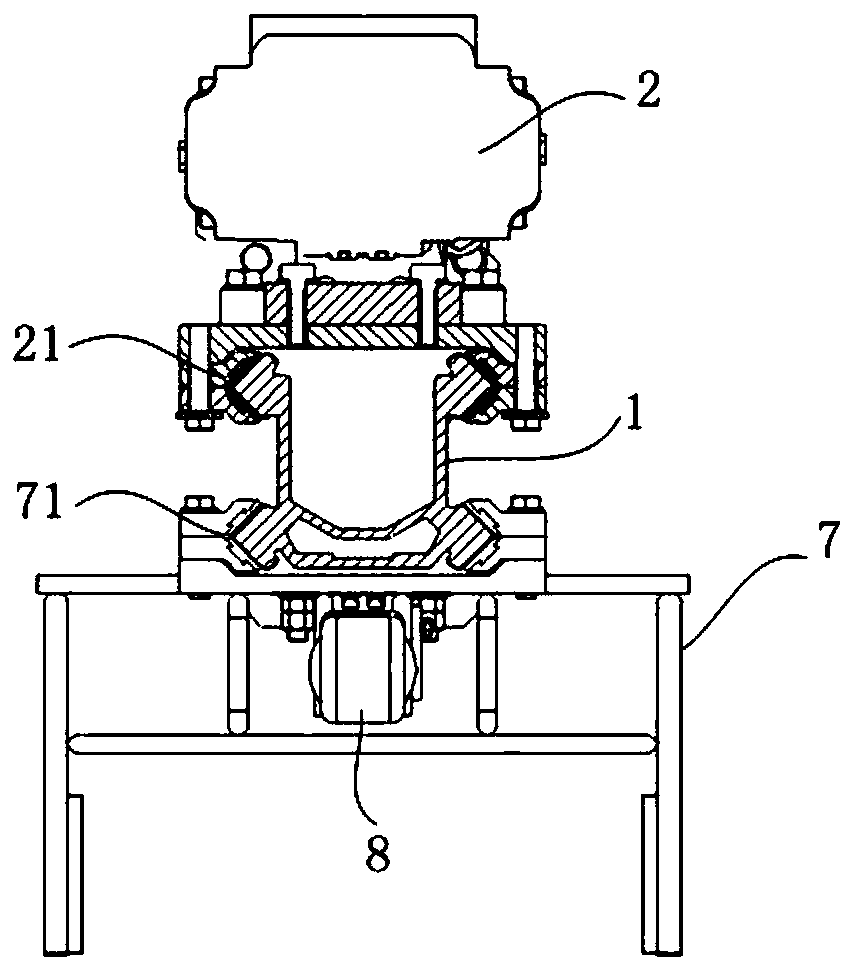

[0038] like Figure 1-13 As shown in the figure, a lead pipe device for drilling a trolley, comprising a beam body 1, a rock drill 2, a drilling oil cylinder 3, a movable pulley block 4, a clamping device 5 and a lead pipe 6, wherein the beam body 1 is as shown in the figure. Figure 4-6 As shown, it is a long strip structure, the right side is the front end, the left side is the rear end, and the material is made of aluminum alloy. The rock drill 2 is seated on the beam body 1 and is slidably connected with the beam body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com