A secondary booster pump for oilfield water injection

A technology of secondary pressurization and oil field water injection, which is applied in the direction of pumps, piston pumps, pump components, etc., and can solve problems such as high energy consumption, low system efficiency, and poor synchronization and coordination of solenoid valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

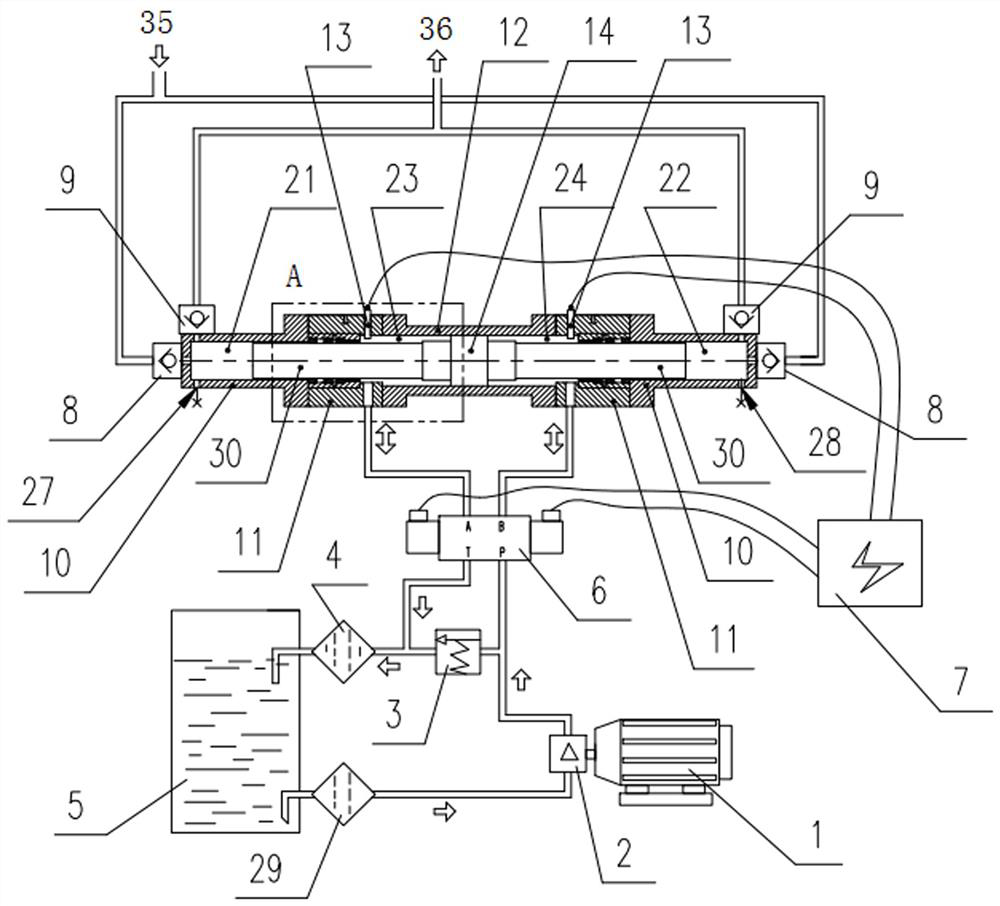

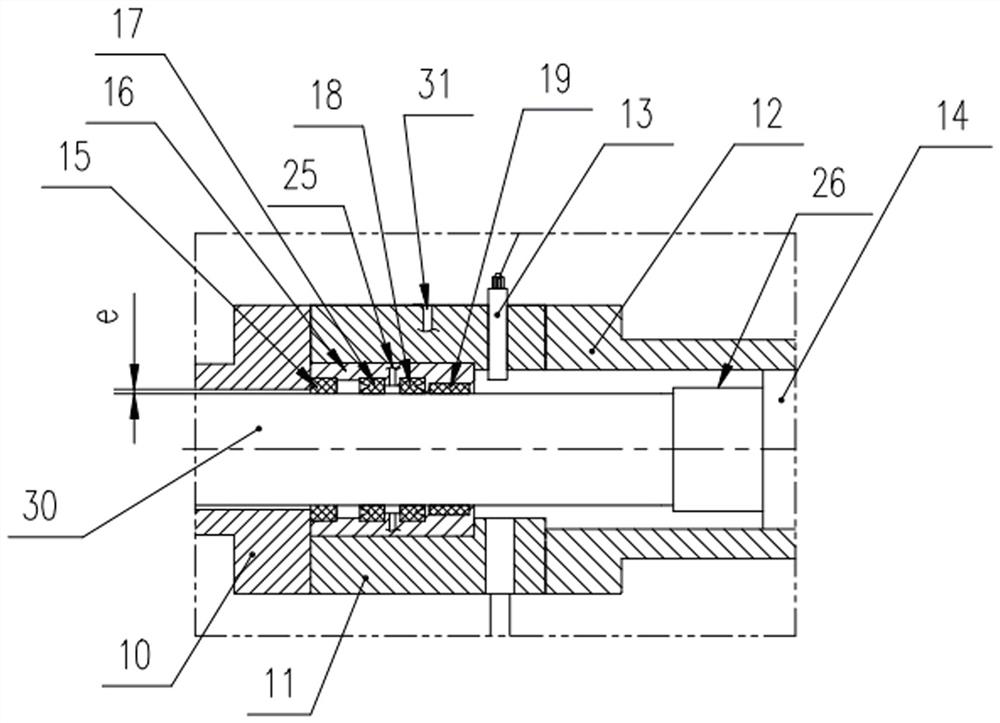

[0037] like figure 1 , figure 2 As mentioned above, the present invention is a secondary booster pump for oil field water injection, and a prime mover 1, a hydraulic pump 2, a safety valve 3, a hydraulic filter 4, a hydraulic oil tank 5, and a hydraulic reversing valve 6 constitute a hydraulic drive system. The output shaft end of the prime mover 1 is connected with the input shaft end of the hydraulic pump 2, the oil inlet of the hydraulic pump 2 is connected with one end of the filter 29, and the other end of the filter 29 is connected with a port of the hydraulic oil tank 5; the hydraulic pump 2 The outlet of the hydraulic reversing valve 6 is divided into two routes, one is connected to the oil inlet port of the hydraulic reversing valve 6, and the other is connected to the inlet of the safety valve 3; One end of the hydraulic filter 4 is connected with one of the ports of the hydraulic oil tank 5 .

[0038] The first working oil port of the hydraulic reversing valve 6 is...

Embodiment 2

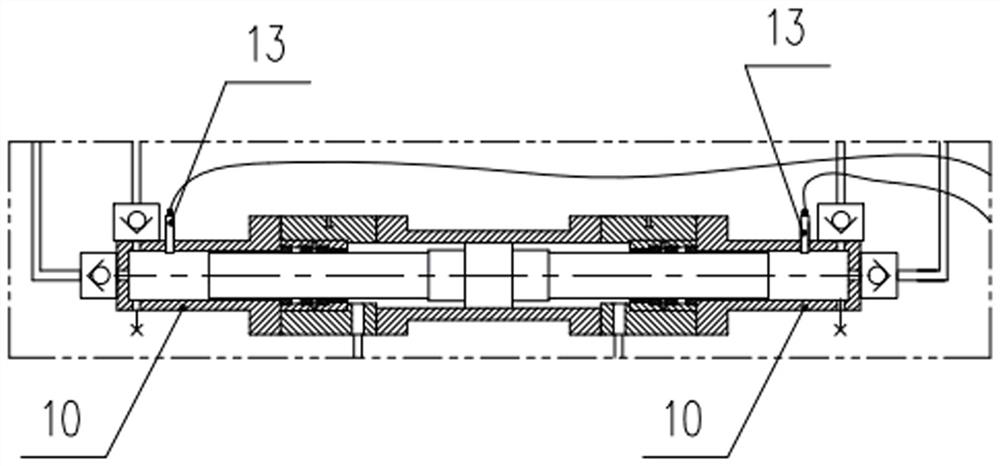

[0071] like image 3 As shown, its connection mode is basically the same as that of Embodiment 1, the difference is that

[0072] The position detection element 13 is installed on the hydraulic cylinder 10 .

Embodiment 3

[0074] like Figure 4 As shown, its connection mode is basically consistent with Embodiment 1, 2, the difference is that, figure 2 The transition connecting body 11 and the guiding process element 16 are combined into an integral connecting body 20 of an integral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com