Novel micro aero-engine combustion chamber

A technology for aero-engines and combustion chambers, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of lack of fixing effect of engine combustion chambers, easily affected flame tube structure design, high requirements for evaporation tubes, etc., and achieve enhanced Oil circuit stability, high strength, and the effect of enhancing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described now in conjunction with accompanying drawing:

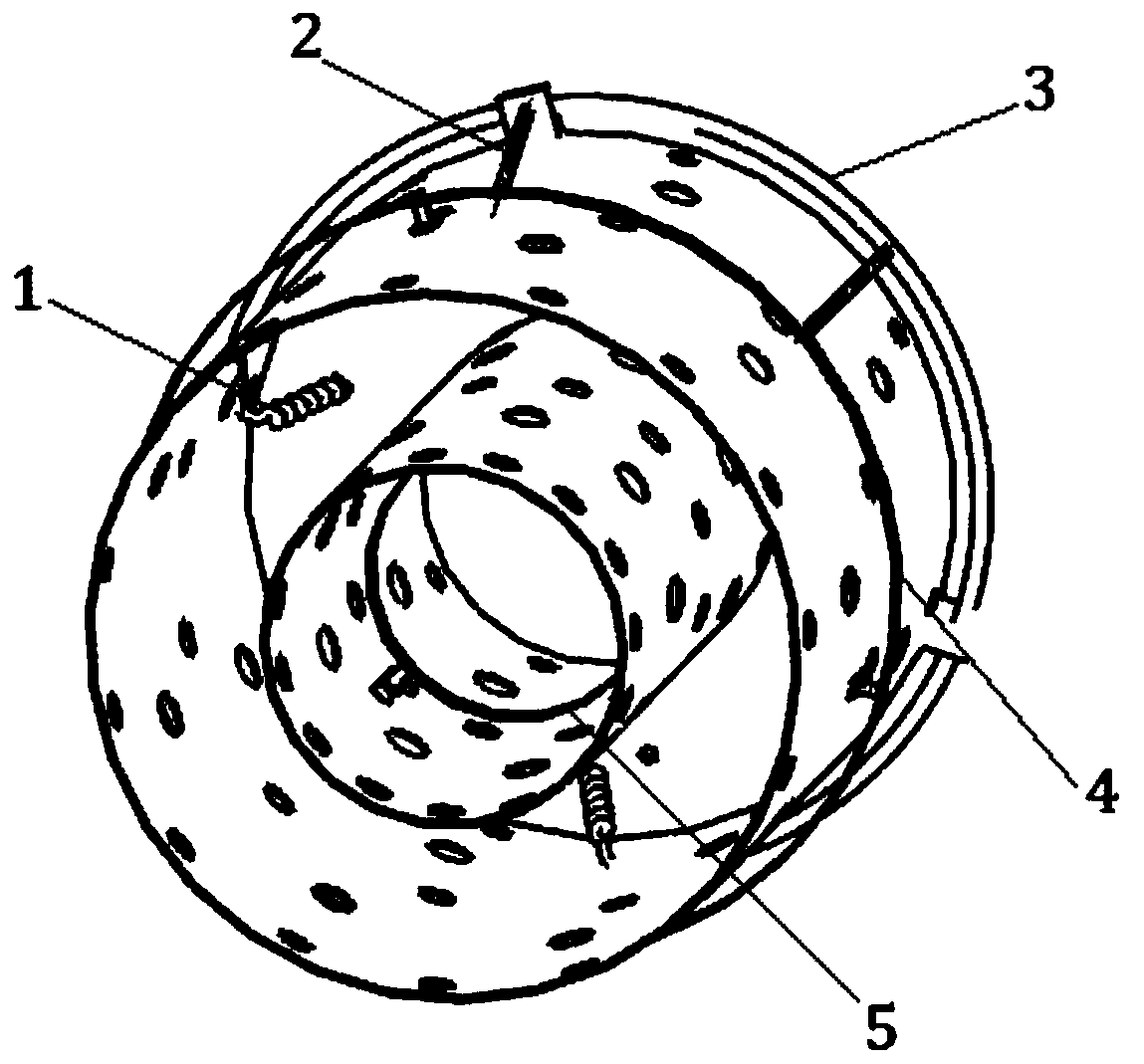

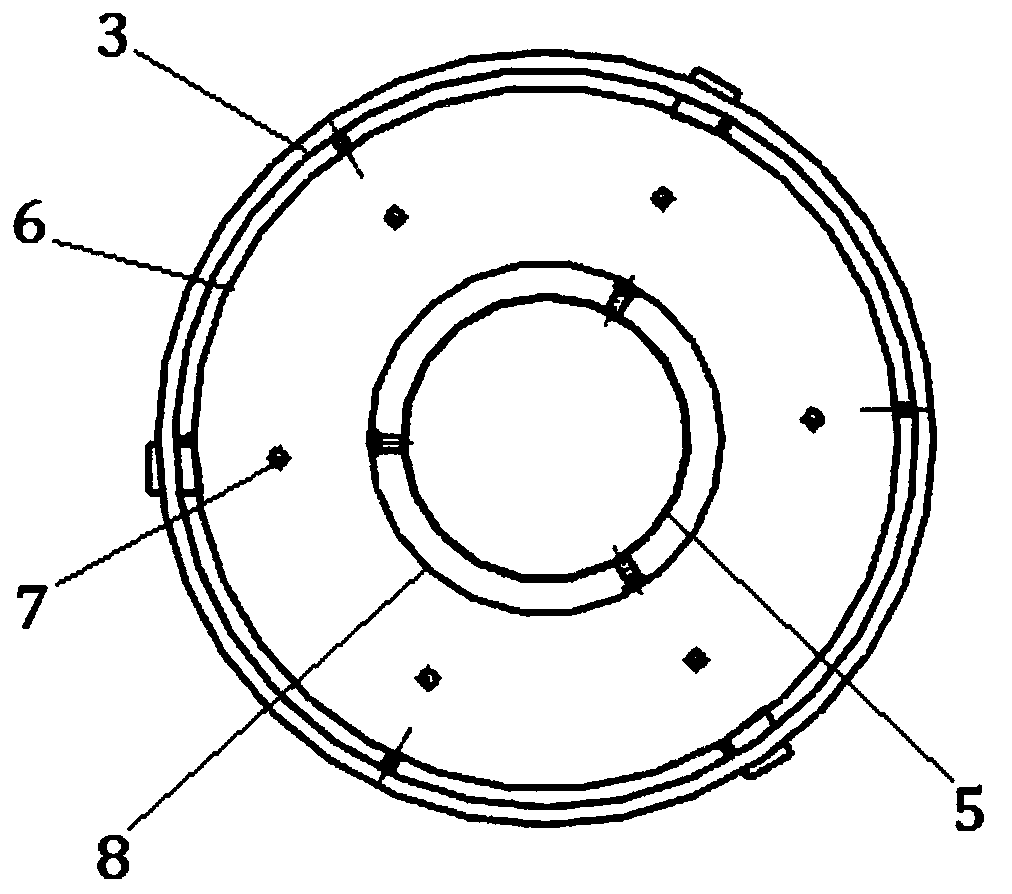

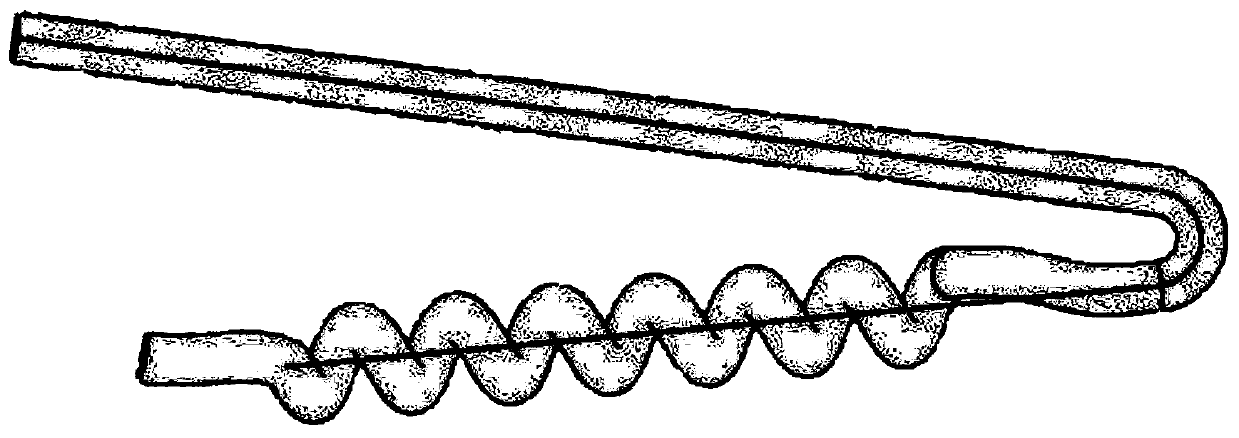

[0025] combine Figure 1-5 , The invention provides a technical scheme of a novel miniature aero-engine combustor. figure 1 It is the overall schematic diagram of the new micro-combustion chamber, figure 2 It is a view of the head structure of the new micro-combustion chamber, image 3 A schematic diagram of a spiral evaporator tube, Figure 4 A detailed drawing of the combustion chamber fixture, Figure 5 An enlarged schematic diagram of the porous medium wall of the flame cylinder.

[0026] To sum up the schematic diagram of the structure, on the one hand, when the combustion chamber is working, the fuel first flows in from the fuel main pipe 3, and flows into the flame tube evenly through the six fuel branch pipes 2. Full preheating is realized in the path, and the spiral structure can improve the stability of the evaporator tube to ensure that it is not deformed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com