BOX-shaped silicon nitride waveguide and preparation method thereof

A technology of forming silicon nitride and silicon nitride, which is applied in the field of BOX-shaped silicon nitride waveguide and its preparation, can solve the problems of insufficiently steep sidewalls, low verticality, and time-consuming, so as to reduce the sidewalls. Scatter loss, reduce process links, improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

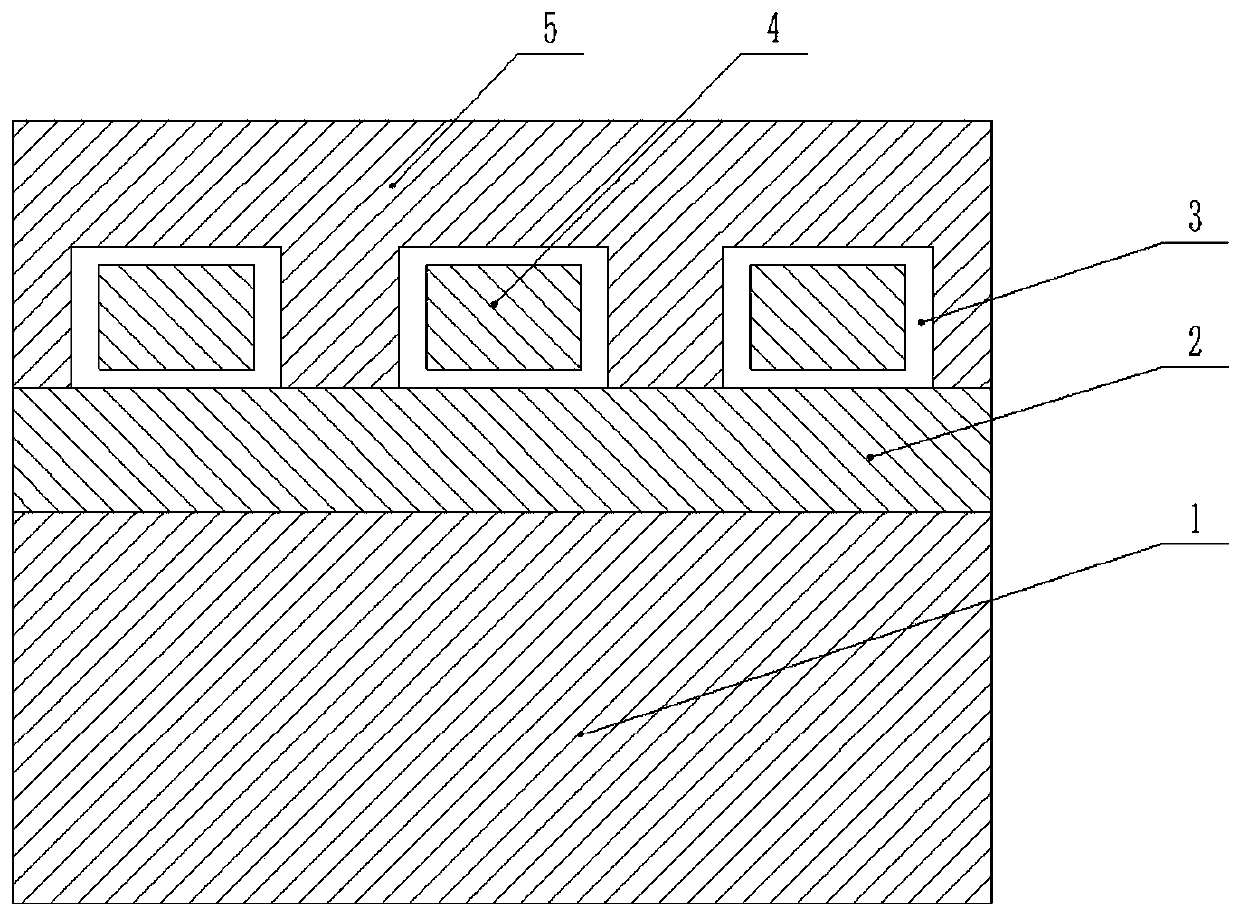

[0053] Such as figure 1 As shown, a BOX-shaped silicon nitride waveguide includes:

[0054] The first cladding layer 2 on the semiconductor substrate 1;

[0055] And the BOX silicon nitride waveguide 3 located on the first cladding layer 2; and the second cladding layer 4 located inside the BOX silicon nitride waveguide 3;

[0056] And a third cladding layer 5 located on the first cladding layer 2 and cladding the BOX silicon nitride waveguide 3;

[0057] The first coating layer 2, the second coating layer 4, and the third coating layer 5 include silicon dioxide;

[0058] The semiconductor substrate 1 is a silicon substrate;

[0059] The thickness of the first coating layer 2 is 3 μm; the thickness of the third coating layer 5 is 7 μm.

[0060] The manufacturing method of the BOX-shaped silicon nitride waveguide of this embodiment includes the following steps:

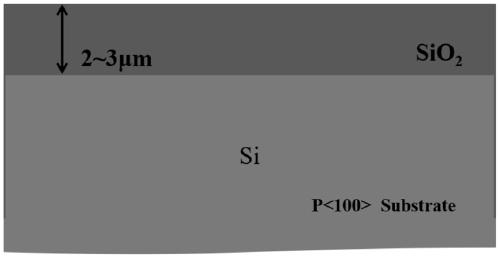

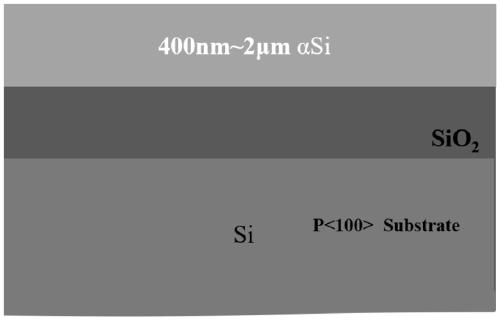

[0061] S1. Such as Figure 2-4 As shown, using thermal oxygen to grow 3μm thick SiO on a silicon substrate 2 Thick film, then in ...

Embodiment 2

[0078] Such as figure 1 As shown, a BOX-shaped silicon nitride waveguide includes:

[0079] The first cladding layer 2 on the semiconductor substrate 1;

[0080] And the BOX silicon nitride waveguide 3 located on the first cladding layer 2; and the second cladding layer 4 located inside the BOX silicon nitride waveguide 3;

[0081] And a third cladding layer 5 located on the first cladding layer 2 and cladding the BOX silicon nitride waveguide 3;

[0082] The first coating layer 2, the second coating layer 4, and the third coating layer 5 include silicon dioxide;

[0083] The semiconductor substrate 1 is a silicon substrate;

[0084] The thickness of the first coating layer 2 is 2 μm; the thickness of the third coating layer 5 is 5 μm.

[0085] The manufacturing method of the BOX-shaped silicon nitride waveguide of this embodiment includes the following steps:

[0086] S1. Such as Figure 2-4 As shown, using thermal oxygen to grow 2μm thick SiO on a silicon substrate 2 Thick film, then in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com