Method for preparing phosphorus removal adsorbent based on natural zeolite synthetic molecular sieve waste

A natural zeolite and phosphorus adsorbent technology, applied in the field of environmental engineering, can solve the problems of high preparation cost, complicated process, and low practical application value, and achieve the effect of realizing waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

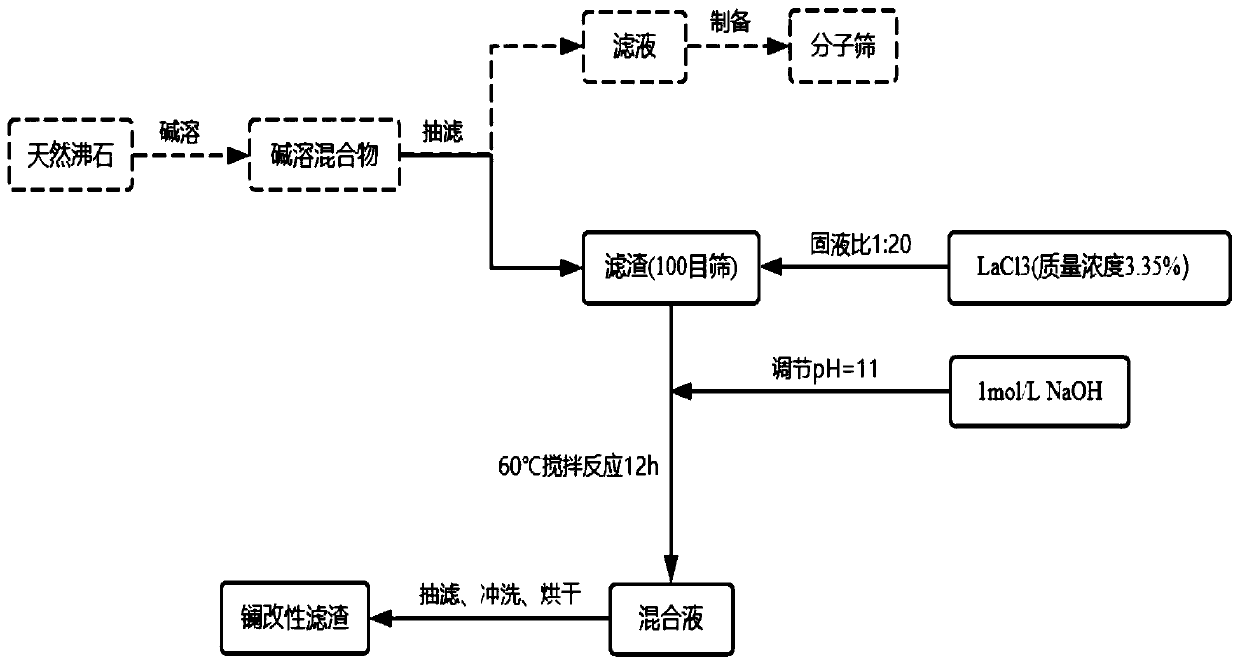

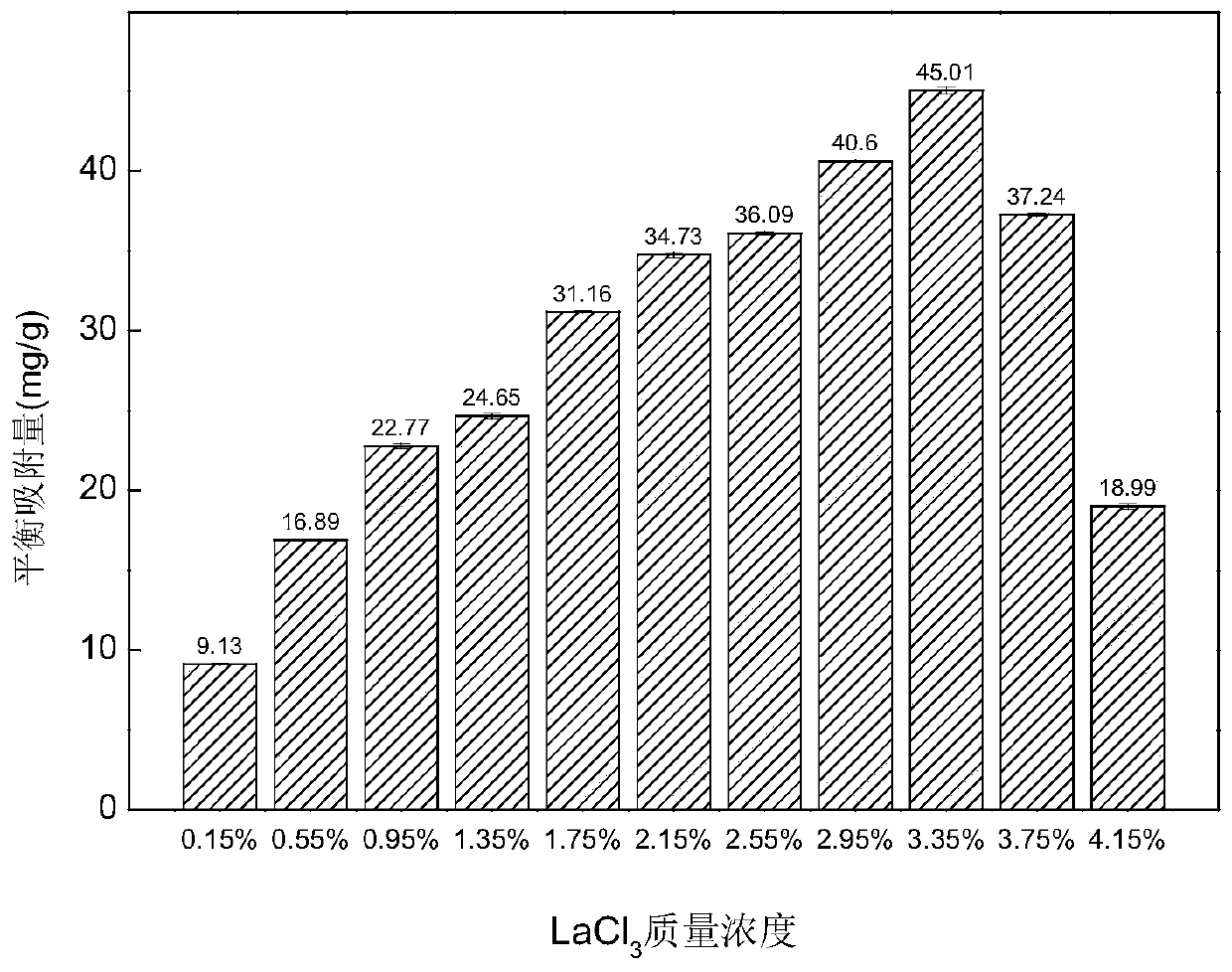

[0025] (1) Concentration of lanthanum solution

[0026] The concentration of the lanthanum solution is set to be 0.15%, 0.55%, 0.95%, 1.35%, 1.75%, 2.15%, 2.55%, 2.95%, 3.35%, 3.75%, 4.15% (mass concentration), and the reaction time is 12h, and A series of lanthanum-modified filter residues were prepared under the same conditions as the previous preparation process.

[0027] Accurately weigh 0.1g of different lanthanum-modified filter residues, put them into 100mL, KH 2 PO 4 Concentration of 50mg / L (in terms of P) in the Erlenmeyer flask. After oscillating at 25°C and 220r / min for 12 hours, the supernatant was taken to measure the concentration of phosphate, and the equilibrium adsorption amount was calculated. (attached image 3 )

[0028] (2) Reaction time

[0029] The reaction time was set to 2, 4, 8, 12, and 16 hours respectively, and a series of lanthanum-modified filter residues were prepared under the conditions of the optimal lanthanum solution concentration and ...

Embodiment

[0033] The preparation of lanthanum-modified filter residue adsorbent: take a certain amount of waste filter residue (grinding, pass 100 mesh sieve) in three-neck flask, add the lanthanum chloride solution that mass percent concentration is 3.35% by solid-liquid mass ratio 1:20, add A certain amount of sodium hydroxide solution is used to adjust the pH value of the mixed solution to 11, and the flask is placed in a magnetic stirrer, and stirred and reacted at 60°C for 12 hours, the mixed solution is suction-filtered, rinsed until the pH is neutral, and then dried to obtain lanthanum Modified filter residue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com