Biochar for heavy metal adsorption and preparation method thereof

A biochar and heavy metal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problem of adsorption and fixation of heavy metals, and achieve the effect of increasing the adsorption and fixation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

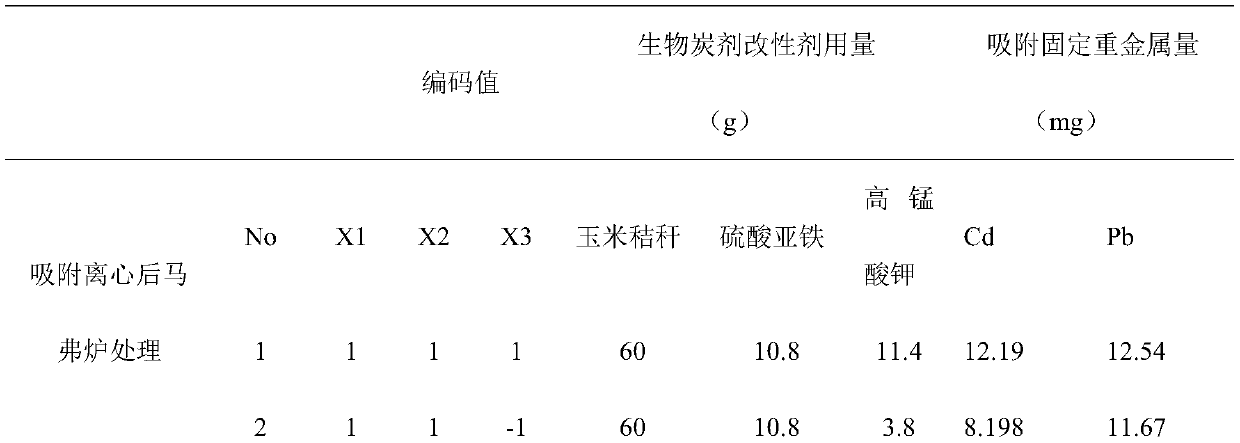

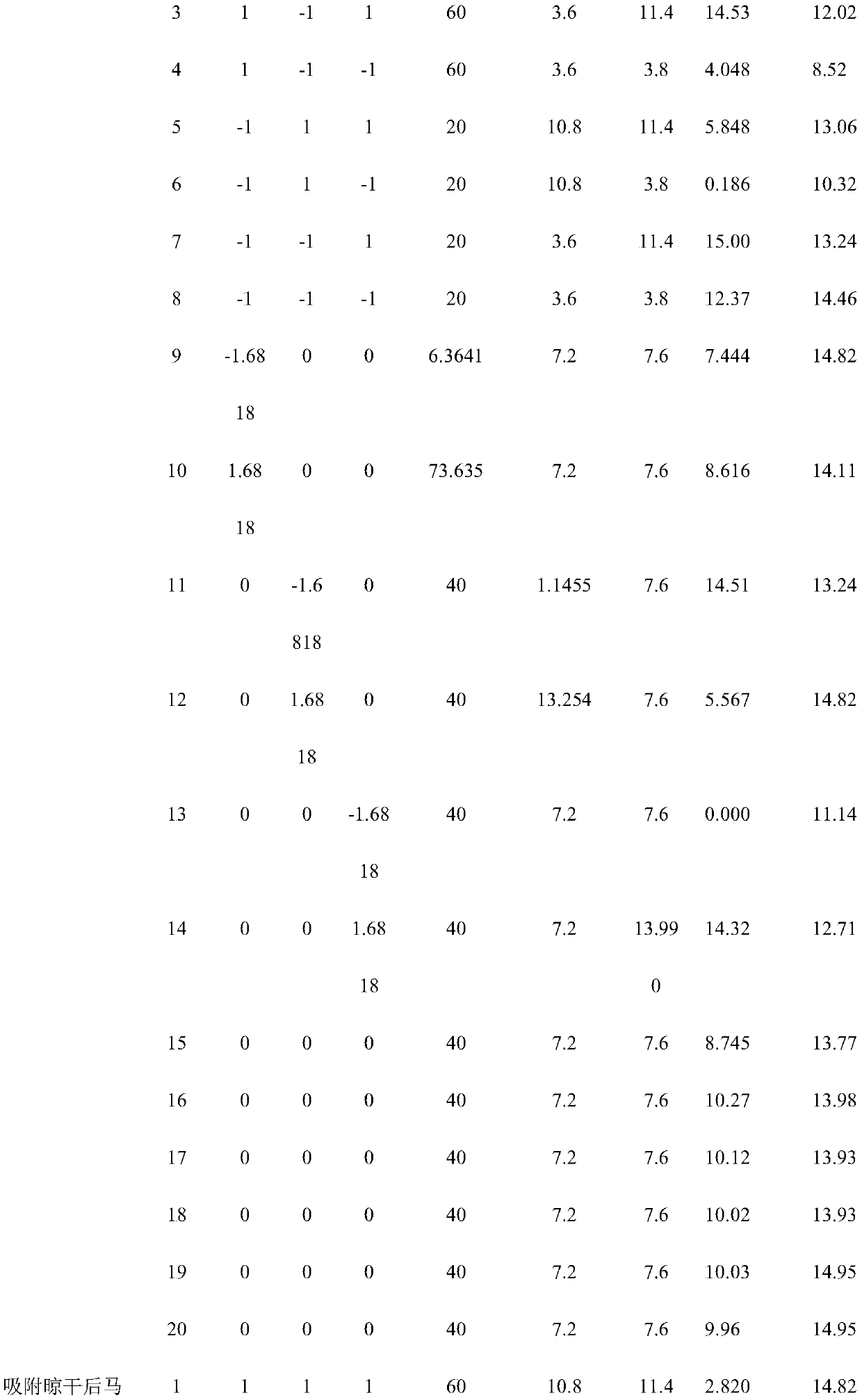

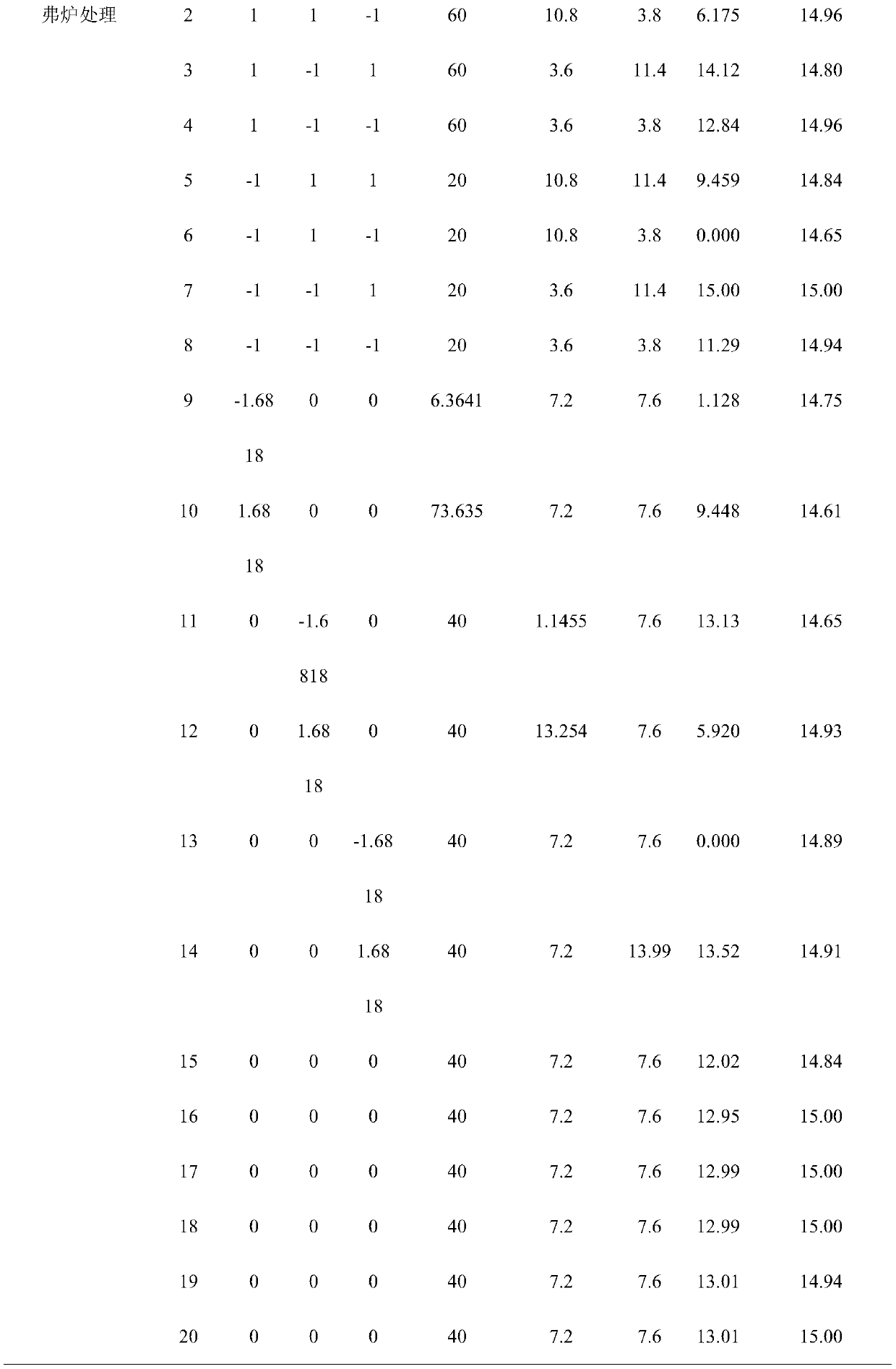

[0015] An embodiment provided by the present invention: a biochar used for heavy metal adsorption, wherein the raw materials for the production of the biochar used for heavy metal adsorption are corn stalks, ferrous sulfate and potassium permanganate.

[0016] The present invention also provides a method for preparing biochar for heavy metal adsorption, comprising the following steps:

[0017] Step 1, weigh ferrous sulfate, potassium permanganate and biochar, put into crucible, add 50ml deionized water, put into sonicator and ultrasonically vibrate, convenient to fully modify;

[0018] Step 2, put the raw materials in step 1 into a centrifuge, separate for 5 minutes under the condition of 4000r / min, and discard the supernatant;

[0019] In step three, the sample in step two is placed in a muffle furnace at 400° C. for 4 hours;

[0020] Step 4: After the pyrolysis is completed and the sample is lowered to room temperature, the solid product is taken out, ground through a 40-me...

Embodiment 2

[0023] A biochar used for heavy metal adsorption, wherein the raw materials for the production of the biochar used for heavy metal adsorption are corn stalks, ferrous sulfate and potassium permanganate.

[0024] A preparation method for biochar for heavy metal adsorption, comprising the following steps:

[0025] Step 1, weigh ferrous sulfate, potassium permanganate and biochar, put them into a crucible, add 50ml of absolute ethanol, put them into an ultrasonicator, and ultrasonically oscillate for 30 minutes at 60°C to facilitate full modification;

[0026] Step 2, place the modified raw material in step 1 on a 100°C electric heating plate to dry;

[0027] Step 3, drying the raw materials in step 2 and putting them into a muffle furnace at 400°C for 4 hours;

[0028] Step 4: After the pyrolysis is completed and the sample is lowered to room temperature, the solid product is taken out, ground through a 40-mesh sieve, and bagged for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com