A hand-pressed physical friction type iron plate single-sided polishing robot for metal processing

A metal processing and single-sided polishing technology, applied in the field of polishing robots, which can solve problems such as low efficiency, slow manual polishing speed, and uneven polishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

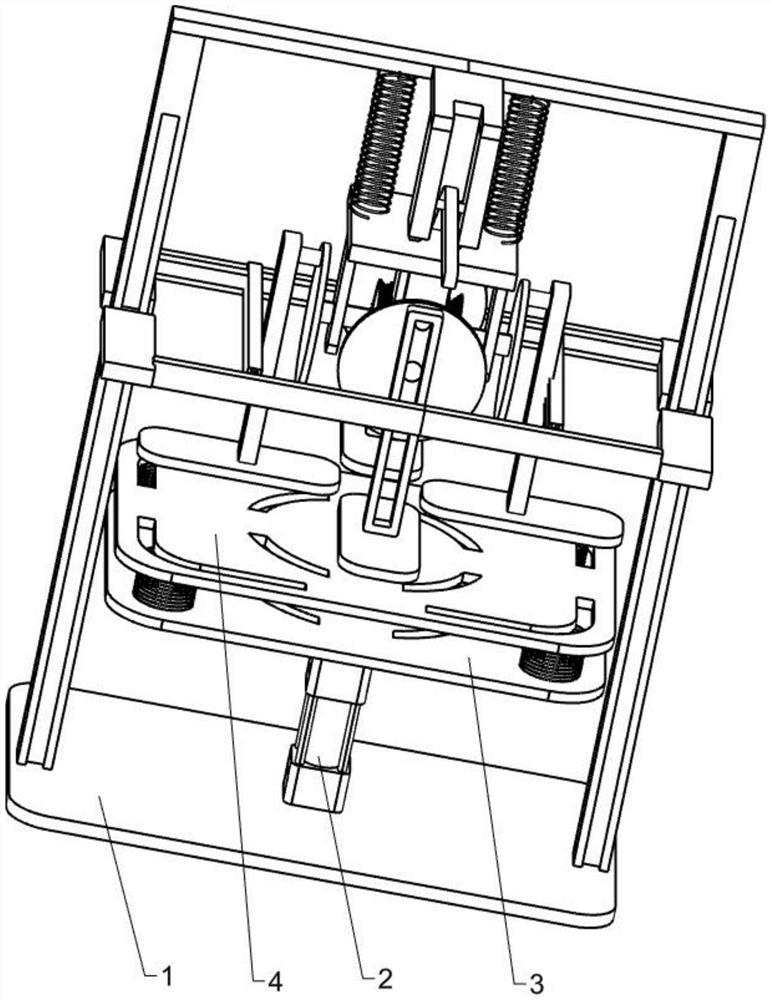

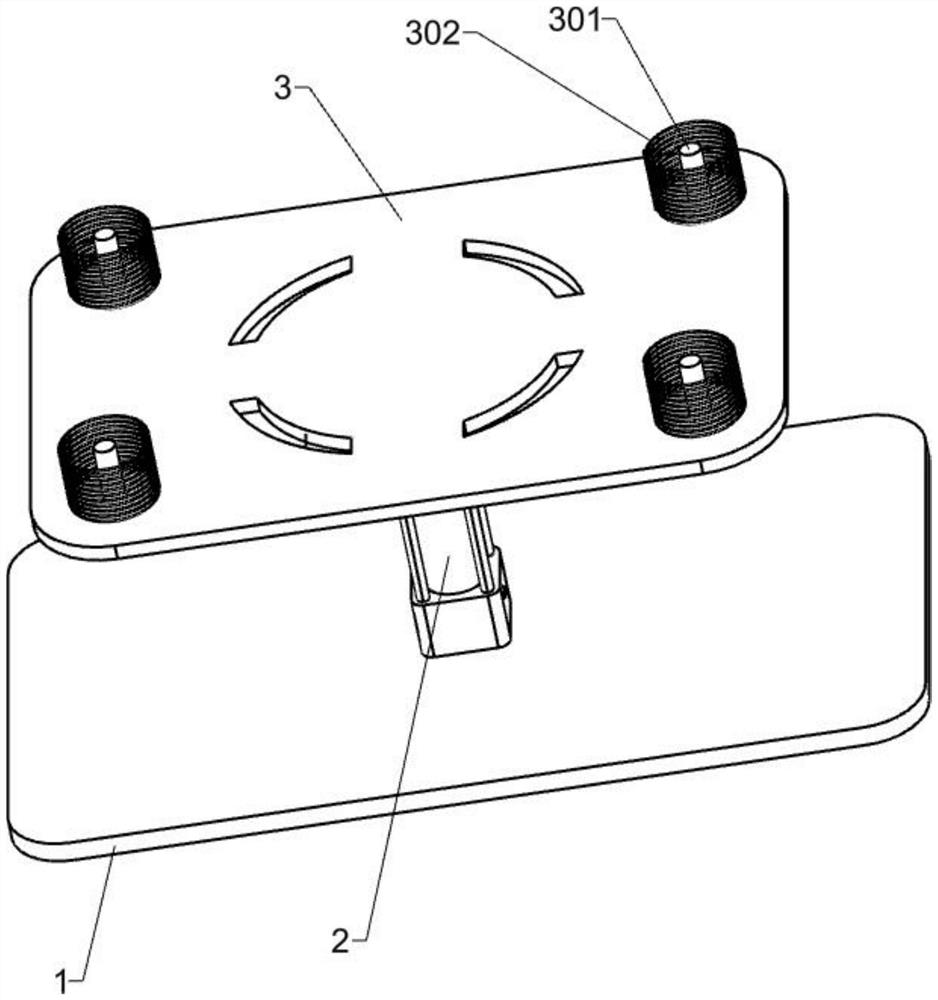

[0050] A hand-pressed physical friction type iron plate single-sided polishing robot for metal processing, such as Figure 1-5 As shown, it includes a base 1, a lifting buffer device, a polishing device and a hand pressing device. The base 1 is long, the lifting buffer device is fixed on the top of the base 1, the polishing device is fixed on the base 1, and the pressing device is fixed on the on the polishing device.

[0051] When working, install the polishing cotton to the polishing device manually, put the iron plate on the lifting buffer device, and then start the lifting buffer device to rise. When it rises to a suitable position, stop rising and then start the polishing device. At the same time, manually Lift the pressure hand device, the pressure hand device moves upwards to drive the polishing device to move down, so that the polishing cotton can polish the iron plate more firmly, when the polishing is completed, manually press the pressure hand device, the pressure h...

Embodiment 2

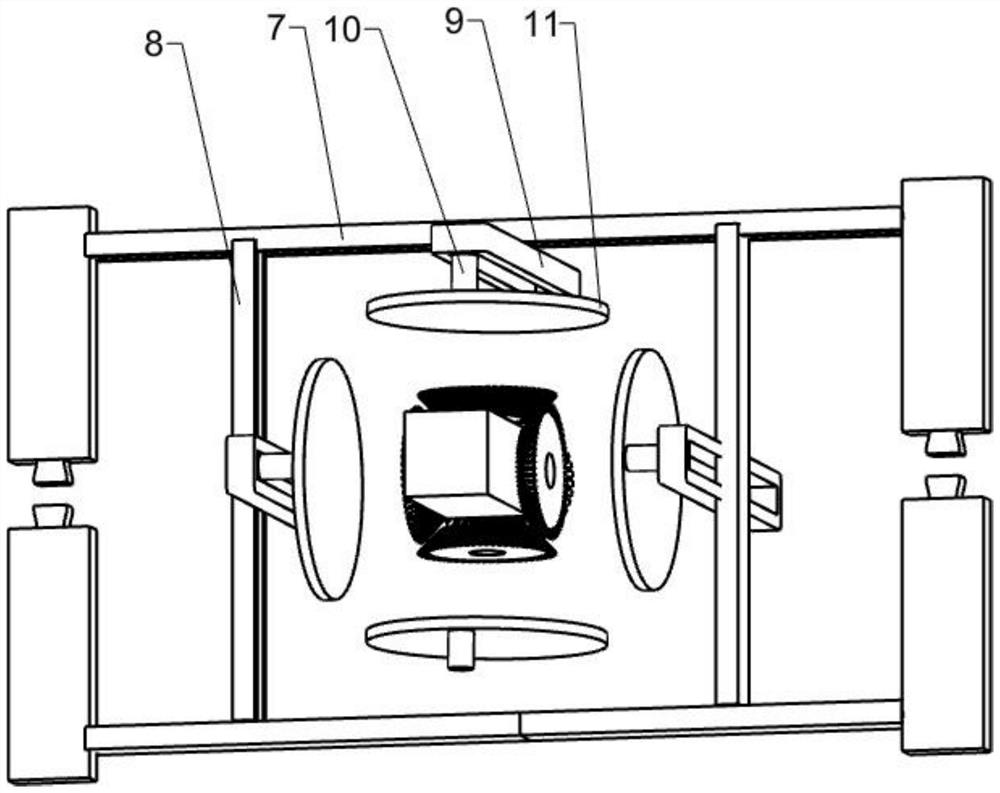

[0057] Based on Embodiment 1, a hand-pressed physical friction type iron plate single-sided polishing robot for metal processing, such as Figure 4-5 As shown, the hand pressing device includes a straight swing seat 18, a hand press bar 19, a curved swing seat 20 and a spring 21, the straight swing seat 18 is fixed on the top of the fixed plate 13, and the hand press bar 19 is hinged on the straight swing seat 18. Curved swing seat 20 is fixedly connected to the two-way slide rail 5 front sides, and the middle part of the pressing lever 19 is hinged to the curved swing seat 20. Two springs 21 are symmetrical, and one end is connected with the two-way slide rail 5, and the other end is connected with the fixed plate 13.

[0058] When polishing is required, manually lift the pressing lever 19 upwards, and the pressing lever 19 moves upwards and drives the polishing device to move downward through the curved swing seat 20 and the straight swing seat 18, so that the polishing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com