Automatic assembly line of panel sockets

An automatic assembly and assembly line technology, applied in the assembly/disassembly of contact pieces, transportation and packaging, circuit/collector components, etc., can solve the problems of low processing efficiency, increased friction, wear of belts and objects, etc., to increase The effect of placing quantity, reducing friction and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

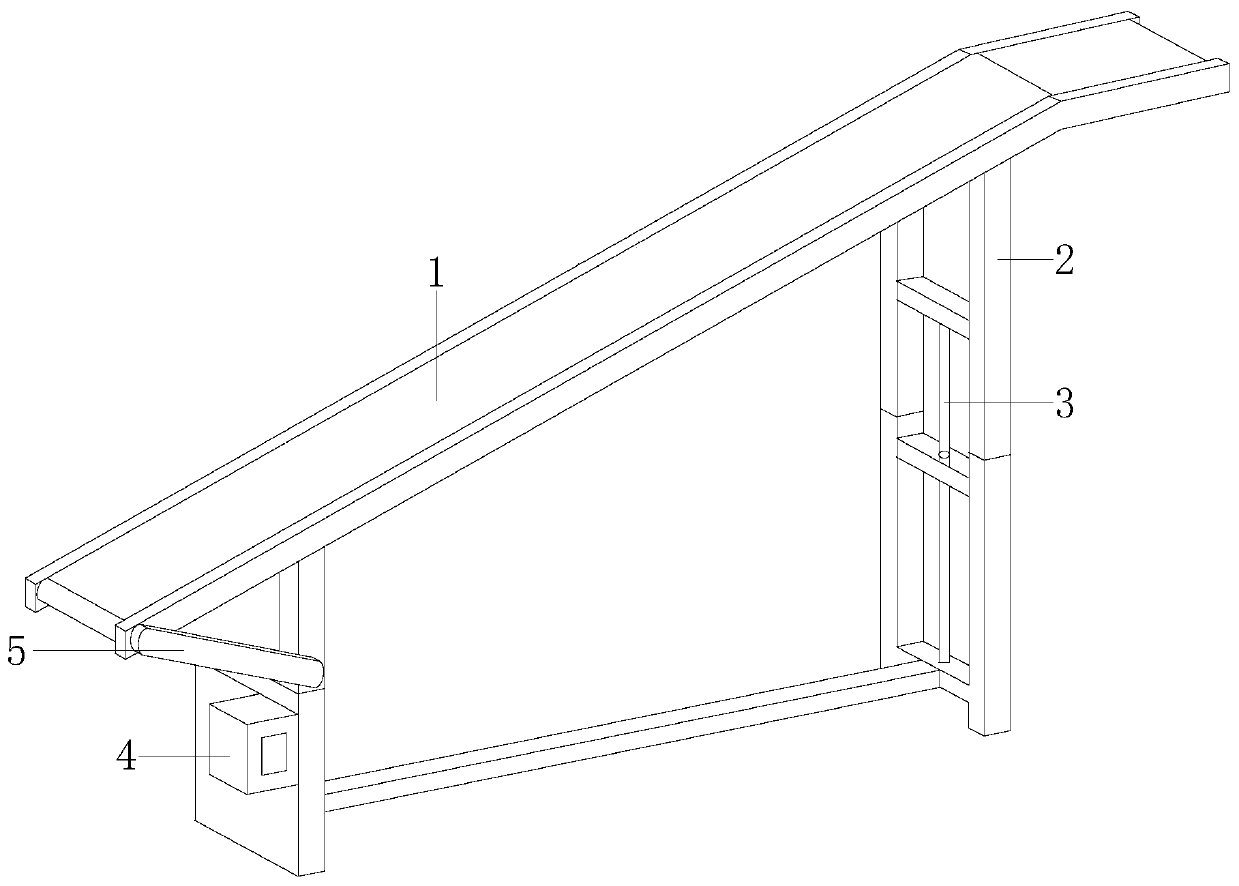

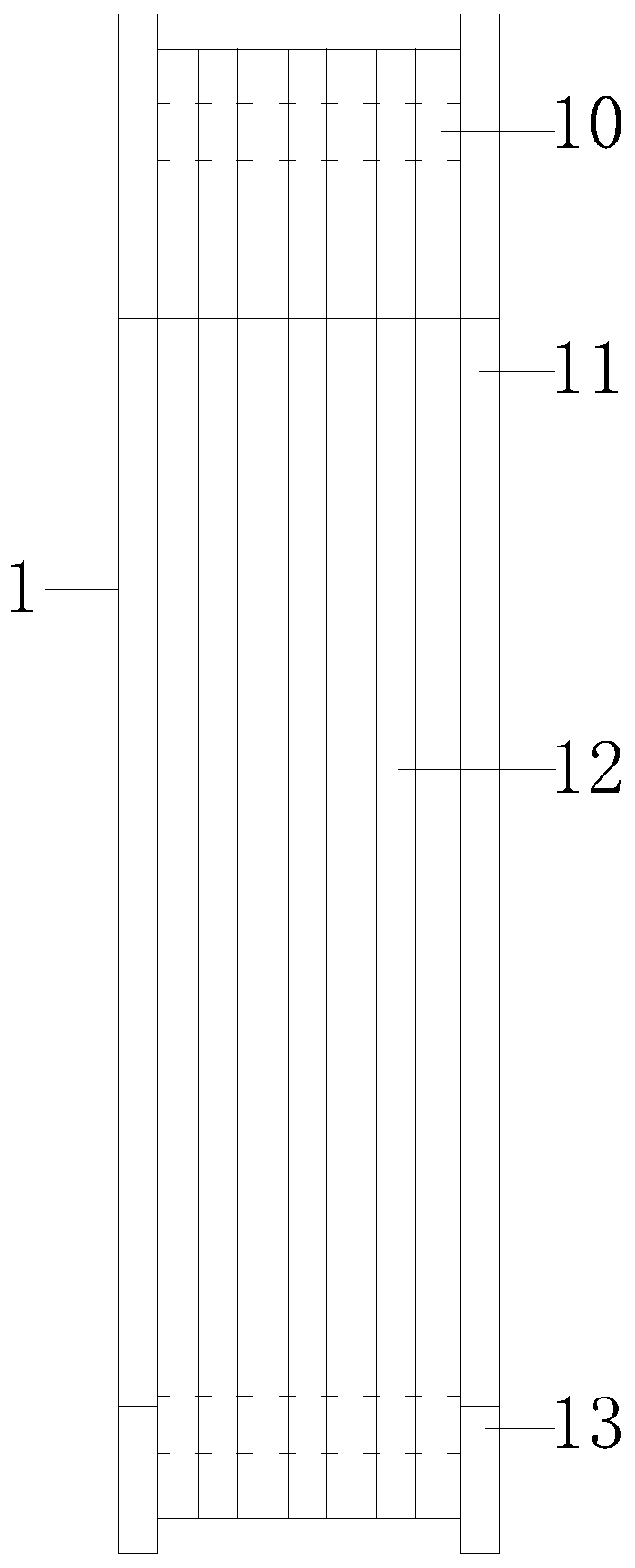

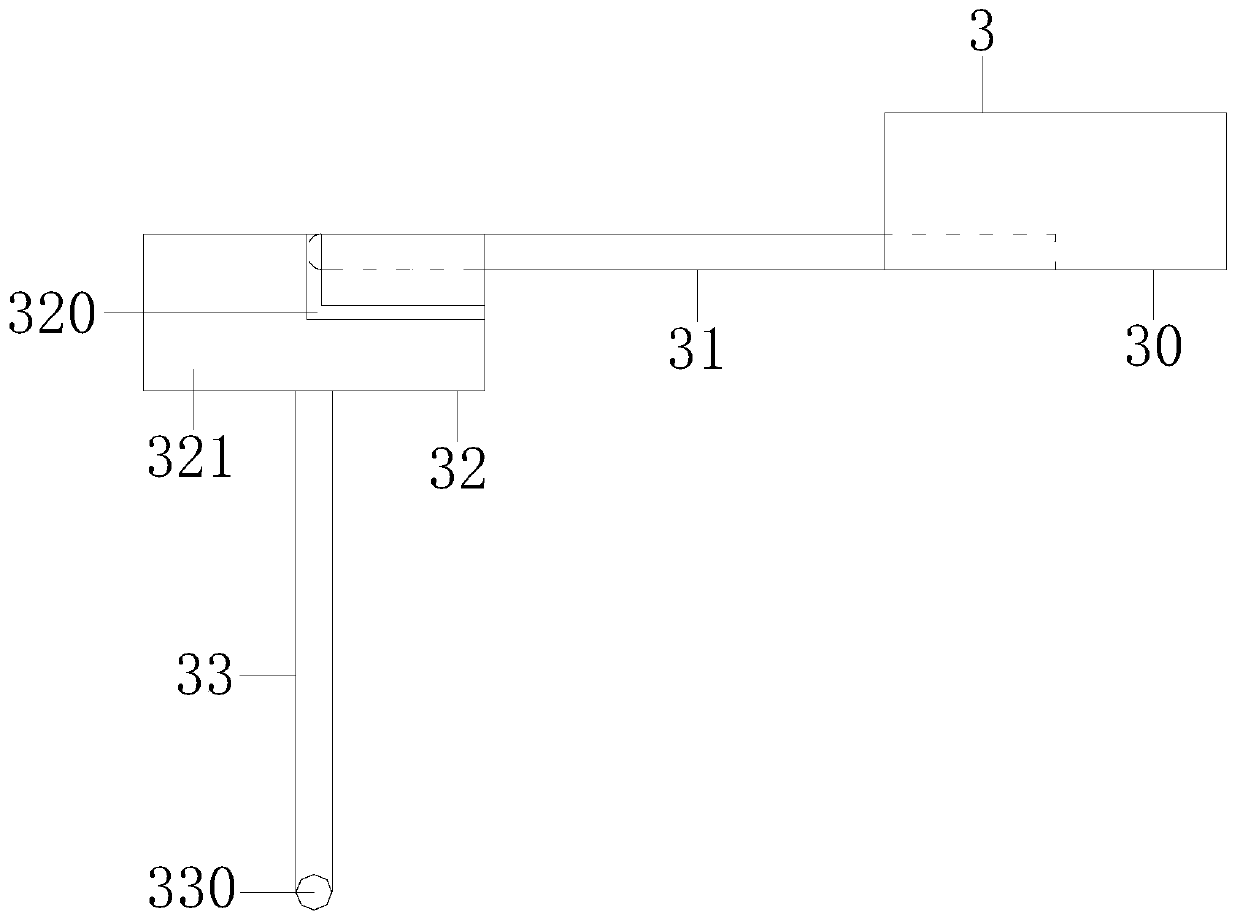

[0026] Example 1 see Figure 1-5 , the present invention provides an automatic assembly line technical solution for panel sockets: its structure includes a transmission line 1, a single-line support 2, a double support 3, a motor 4, and a pole 5, the transmission line 1 is locked with the single-line support 2, and the The single-line support 2 is installed and connected with the double support 3, the double support 3 is locked with the motor 4, the double support 3 is connected with the pole 5 shafts, and the conveying line 1 is composed of a top piece structure 10, a conveying side frame 11, a single branch Line 12, inner shaft structure 13, and shifting structure 14. The top piece structure 10 is installed on the conveying side frame 11 and the single branch line 12. The conveying side frame 11 is connected to the single branch line 12. The conveying The side frame 11 is equipped with an inner shaft structure 13. The double bracket 3 includes an upper top block 30, a middle...

Embodiment 2

[0028] Example 2 see Figure 6-7, the present invention provides an automatic assembly line technical solution for panel sockets: the structure of the top piece structure 10 includes a side layer 100, a support bar 101, and a swing structure 102. When the line and the line are handed over, the top piece structure 10 starts To reduce the friction generated when the object is transported, the side layer 100 is buckled with the support bar 101, and the support bar 101 is locked with the swing structure 102. The swing structure 102 includes a swing rail shaft 1020, a telescopic slide frame 1021, filling material opening 1022, filling material rod 1023, auxiliary side swing 1024, the cushion material in the filling material rod 1023 will move at the filling material opening 1022 according to the movement of the telescopic carriage 1021, so as to improve the movement of objects with The degree of fit of the conveyor belt improves the stability of the transfer. The shifting rail shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com