Energy-saving heating diatom ooze as well as preparation method and application thereof

A technology of diatom mud and diatomite, which is applied in the field of building energy-saving materials, can solve the problems of human health hazards, volatilization, and indoor heating energy saving and consumption reduction, and achieves mild conditions, good interaction, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the energy-saving heating diatom ooze described in the above technical solution, comprising the following steps:

[0065] a) After mixing the diatomite with the filler, add the gelling agent, tourmaline powder and functional additives in sequence and mix evenly, and obtain the energy-saving heating diatom mud after toning.

[0066] In the invention, firstly, the diatomite is mixed with the filler to obtain uniformly mixed materials. In the present invention, the diatomaceous earth and the filler are the same as those in the above technical solution, and will not be repeated here. The present invention has no special limitation on the mixing device, and a stirring tank well known to those skilled in the art can be used. In the present invention, the mixing temperature is preferably 5°C to 40°C, more preferably 25°C.

[0067] After obtaining the homogeneously mixed material, the present invention sequentially ad...

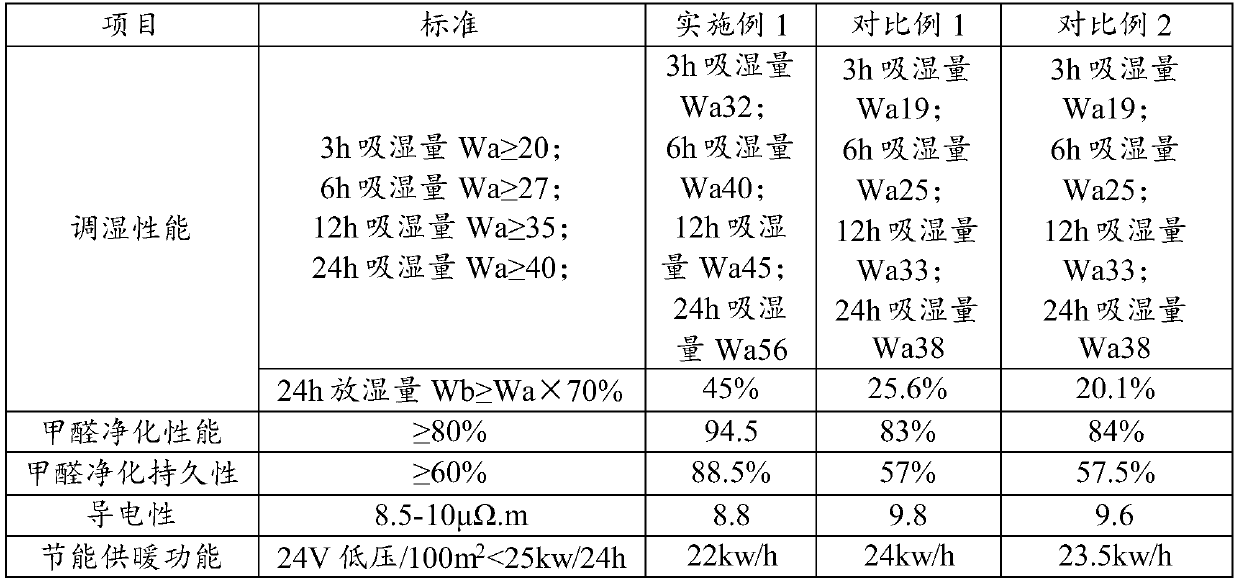

Embodiment 1

[0082] (1) 40 parts by weight of diatomaceous earth, 35 parts by weight of heavy calcium carbonate, 20 parts by weight of lime calcium powder, and 15 parts by weight of talcum powder are mixed uniformly in a stirring tank whose temperature is 25° C. and whose rotating speed is 40 r / min; Add 0.8 parts by weight of redispersible latex powder, 0.7 parts by weight of hydroxypropyl methylcellulose and mix evenly; finally add 0.8 parts by weight of tourmaline powder, 1 part by weight of silver powder, 1 part by weight of nano-aluminum powder, and 3 parts by weight of nano-graphite ethylene and 3 parts by weight of carbon fiber, stirred for 15 minutes, and obtained energy-saving heating diatom mud after toning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com