Nickel-cobalt-based wrought superalloy and preparation method thereof

A technology for deforming high-temperature alloys and high-temperature alloys, which is applied in the field of high-temperature alloys to achieve excellent heat and corrosion resistance, no pollution cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

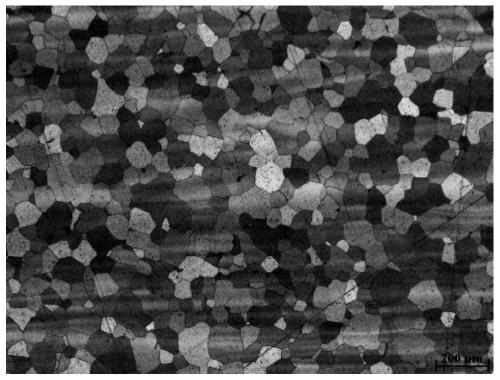

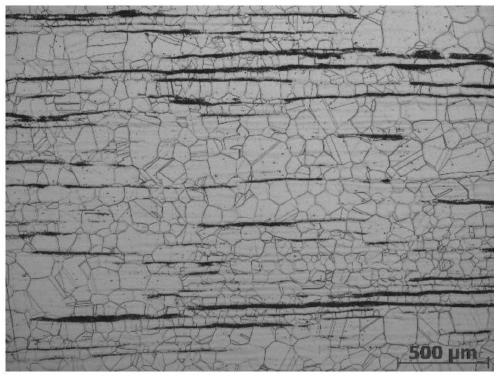

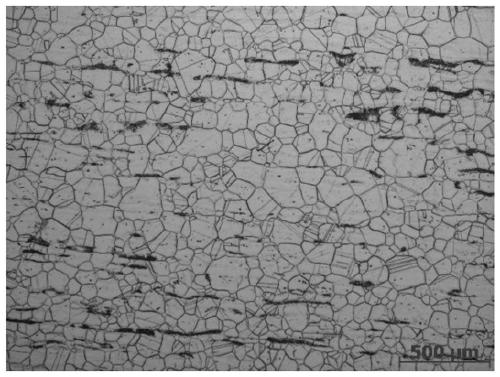

Image

Examples

preparation example Construction

[0051] Specifically, the preparation method of the nickel-cobalt-based deformed superalloy provided in the embodiment of the present invention includes the following steps:

[0052] Solution treatment: the hot-rolled sheet (that is, the nickel-cobalt-based superalloy after hot-rolling treatment) is solution-treated at a temperature of 0.85-0.95Tm for 2-4h, and then water-cooled to room temperature, and the solution-treated sheet is Pickling and drying. Here, the Tm mentioned in the present invention refers to the melting point temperature of the nickel-cobalt-based superalloy.

[0053] Deformation treatment: cold rolling the plate after solid solution treatment with a total deformation of 50-80%, lubricated with emulsion, and the reduction rate of each pass is 10-15%.

[0054] Annealing treatment: Before annealing, wash and dry the cold-rolled sheet with alkali, then anneal the cold-rolled sheet at a temperature of 0.8-0.9Tm in a vacuum or a hydrogen-reducing environment for ...

Embodiment 1

[0062] In this embodiment, a nickel-cobalt-based deformed superalloy is prepared, which includes the following steps:

[0063] Preparation of ingots: Put the raw materials into a high-frequency vacuum induction melting furnace, heat the temperature to 1500°C, and the vacuum degree is 0.5×10 -2Pa, after all the raw materials are melted, it is refined at a temperature of 1550°C for 6 minutes, and then an inert gas is introduced, and a crucible is cast into an ingot. Among them, the formula of raw materials is as follows: Co 25%, Ta 2%, Cr 15%, Ti 5.5%, Al 2%, W 2%, Mo 2%, Nb 1%, Mn 0.5%, V 0.1%, C 0.003% , Zr 0.02%, B 0.02%, and the balance is Ni. Among them, the Tm of the nickel-cobalt-based superalloy is 1335°C, and the solid solution temperature of the precipitated phase is 1160°C.

[0064] Preparation of electroslag refining ingot: After the ingot is cooled, cut the riser of the ingot and polish the surface, use the polished ingot as the electrode of electroslag remelting,...

Embodiment 2

[0072] In this embodiment, a nickel-cobalt-based deformed superalloy is prepared, which includes the following steps:

[0073] Preparation of ingots: Put the raw materials into the high-frequency vacuum induction melting furnace according to the above ratio, heat the temperature to 1600°C, and the vacuum degree is 0.6×10 -2 Pa, after all the raw materials are melted, refine at a temperature of 1550°C for 5 minutes, then pass in an inert gas, and cast a crucible into an ingot. Among them, the formula of raw materials is as follows: Co 25%, Ta 2%, Cr 15%, Ti 5.5%, Al 2%, W2%, Mo 2%, Nb 1%, Mn 0.5%, V 0.1%, C 0.003%, Zr 0.02%, B 0.02%, and the balance being Ni. Among them, the Tm of the nickel-cobalt-based superalloy is 1335°C, and the solid solution temperature of the precipitated phase is 1160°C.

[0074] Preparation of electroslag refining ingot: After the ingot is cooled, cut the riser of the ingot and polish the surface, use the polished ingot as the electrode of electrosl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com