Preparation method of surface roughness resistant roller for heavy and medium plate mill

A technology of rough surface, plate rolling mill, applied in the field of roll manufacturing, can solve the problems of low wear resistance, adverse effects on roll neck structure and performance, etc., and achieve the effect of reducing roll wear, good roll surface retention ability, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

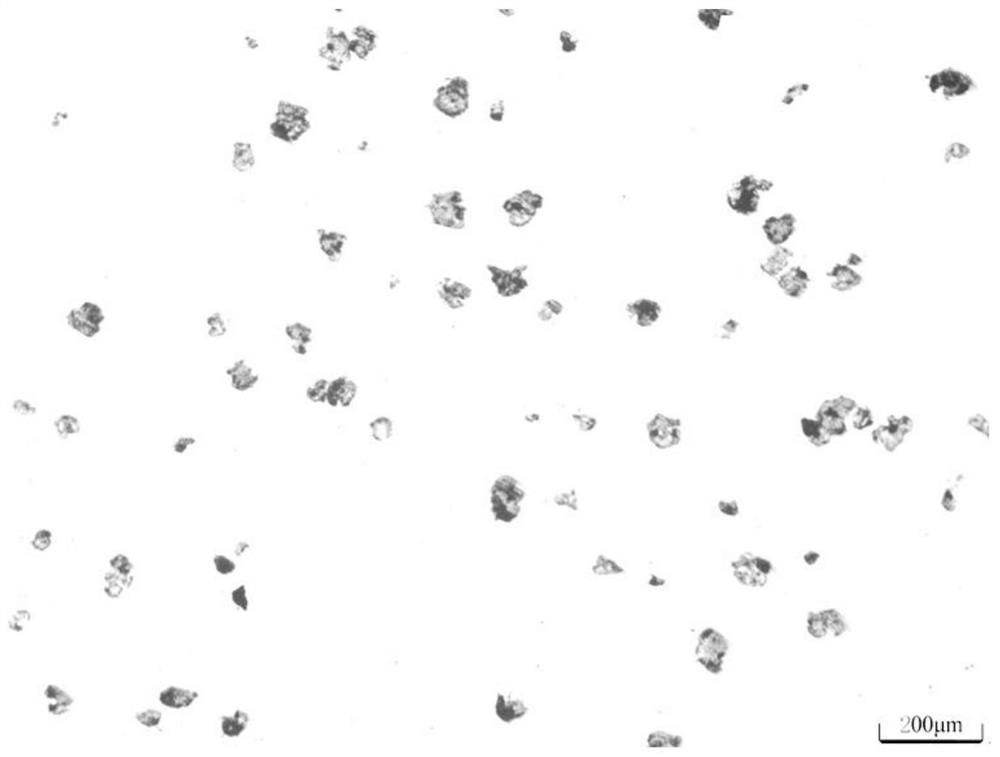

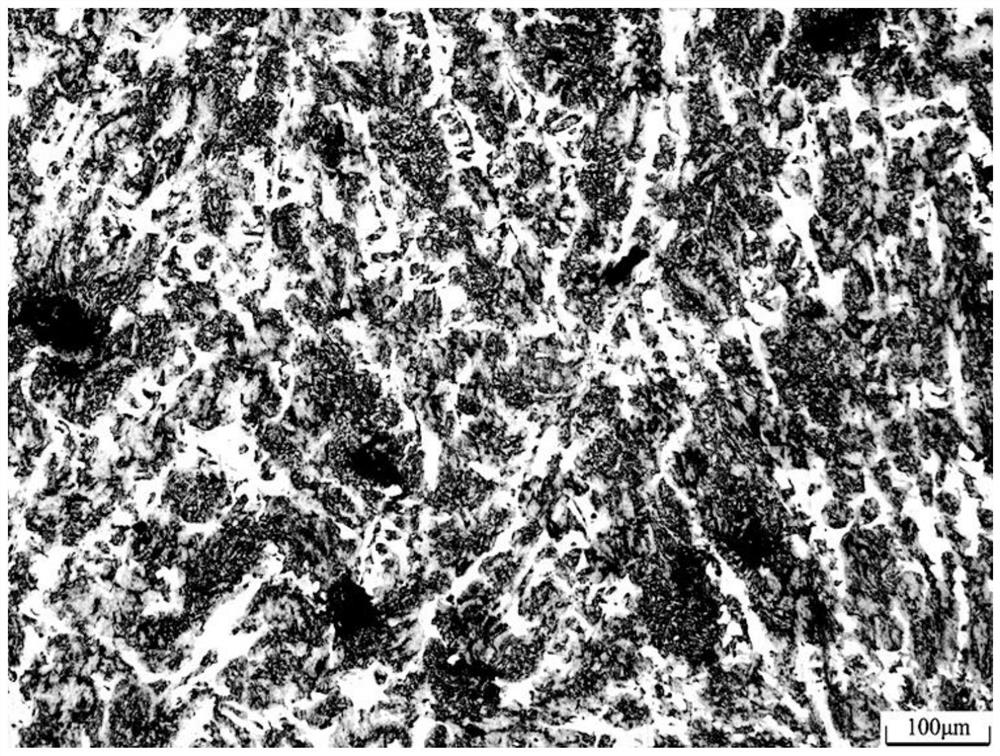

Image

Examples

preparation example Construction

[0030] A preparation method of an anti-rough surface roll for a plate rolling mill, comprising the following steps:

[0031] Step 1. Use steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder as raw materials, and use a power frequency furnace to smelt the molten iron in the outer layer of the roll and the molten iron in the core of the roll. The melting temperature of the molten iron in the outer layer of the roll is 1400-1700 °C, the melting temperature of the molten iron at the core of the roll is 1300-1600 °C until the melting composition meets the design composition requirements;

[0032] Ferronickel can be replaced by nickel plate, and ferromolybdenum can be replaced by alloy molybdenum. The above materials can also be compounds of multi-element alloys, as long as the composition ratio meets the requirements of the alloy range.

[0033] The chemical composition of the outer layer of the roll and the weight percentage of each composi...

Embodiment 1

[0049] A preparation method of an anti-rough surface roll for a plate rolling mill, comprising the following steps:

[0050] Step 1, using steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder as raw materials, smelting in an intermediate frequency furnace to reach the design composition range of ductile iron: the chemical composition of molten iron in the outer layer of the roll and the weight percentage of each composition are : C3.33%, Si1.1%, Mn0.9%, P0.05%, S0.06%, Cr0.8%, Ni2.1%, Mo0.85%, W+V+Nb=0.15%, The balance is Fe and unavoidable impurities; the chemical composition of molten iron in the core of the roll and the weight percentage of each composition are: C3.01%, Si1.5%, Mn0.8%, P0.08%, S0.09% , Cr0.05%, Ni0.1%, Mo0.1%, W+V+Nb=0.06%, and the balance is Fe.

[0051] Step 2: The molten iron on the outer layer of the roll is smelted at a temperature of 1610°C. After the composition meets the design requirements, the temperature ...

Embodiment 2

[0056] A preparation method of an anti-rough surface roll for a plate rolling mill, comprising the following steps:

[0057] Step 1: Use steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder as raw materials, and smelt them in an intermediate frequency furnace to reach the design composition range of ductile iron:

[0058] The chemical composition of molten iron in the outer layer of the roll and the weight percentage of each composition are: C2.80%, Si1.0%, Mn0.8%, P0.06%, S0.08%, Cr0.9%, Ni2.89% , Mo0.79%, W+V+Nb=0.12%, the balance is Fe; the chemical composition of molten iron in the core of the roll and the weight percentage of each composition are: C2.95%, Si1.45%, Mn0.75% , P0.06%, S0.08%, Cr0.03%, Ni0.25%, Mo0.05%, W+V+Nb=0.03%, the balance is Fe and unavoidable impurities.

[0059] Step 2: The molten iron on the outer layer of the roll is smelted at a temperature of 1611°C. After the composition meets the design requirements, th...

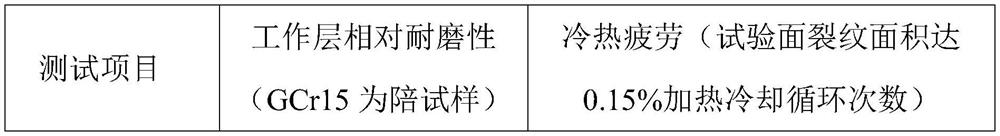

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com