Flux cored wire for impact-resistant nonstick steel overlaying

A tubular welding wire, impact-resistant technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor welding performance, hot cracks and sticking to steel, and achieve low manufacturing costs and strong impact resistance. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiments.

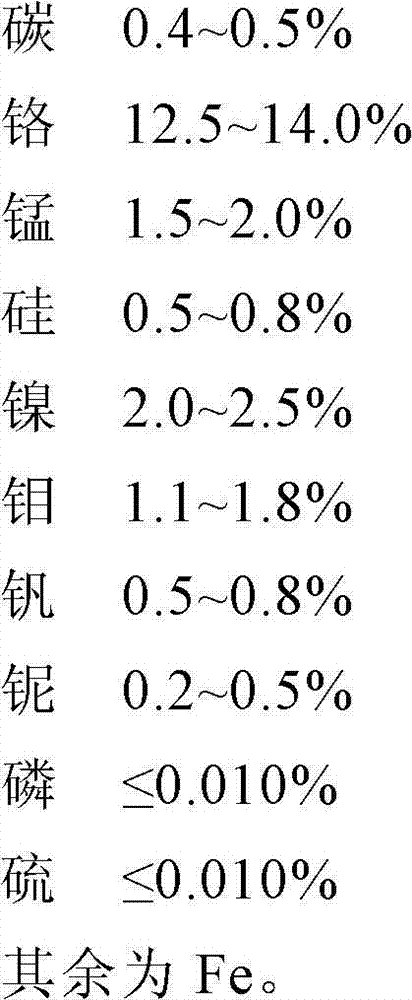

[0033] The components of the examples are shown in Table 1, which are prepared by conventional tubular welding wire manufacturing methods.

[0034] Overlay welding repair vertical roll stand roll:

[0035] 1) Preparation before welding

[0036] ①Inspect and machine the roller table to remove defects and fatigue layers:

[0037] ②The welding power source adopts MZ.1-1000 automatic submerged arc welding machine;

[0038] ③The welding wire in the welding materials should not have rust, oil and other debris. The flux must be baked at 200~300℃ for 5h before use to remove water;

[0039] ④ The rotating speed of the surfacing turntable is stable and should be able to ensure the uniformity of the surfacing weld.

[0040] 2) Preheat before welding

[0041] Because the carbon equivalent of the surfacing roller table material is Ceq=C+Mn, / 6+Si / 24+Cr / 5+Mo / 4=0.68 is relatively high, and the weldability is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com