Aluminum metal surface oxidation treatment equipment

A surface oxidation treatment, aluminum metal technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems affecting the physical properties and appearance of aluminum alloy workpieces, uneven oxidation of aluminum alloy workpieces, etc., to achieve improved oxidation Uniformity, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

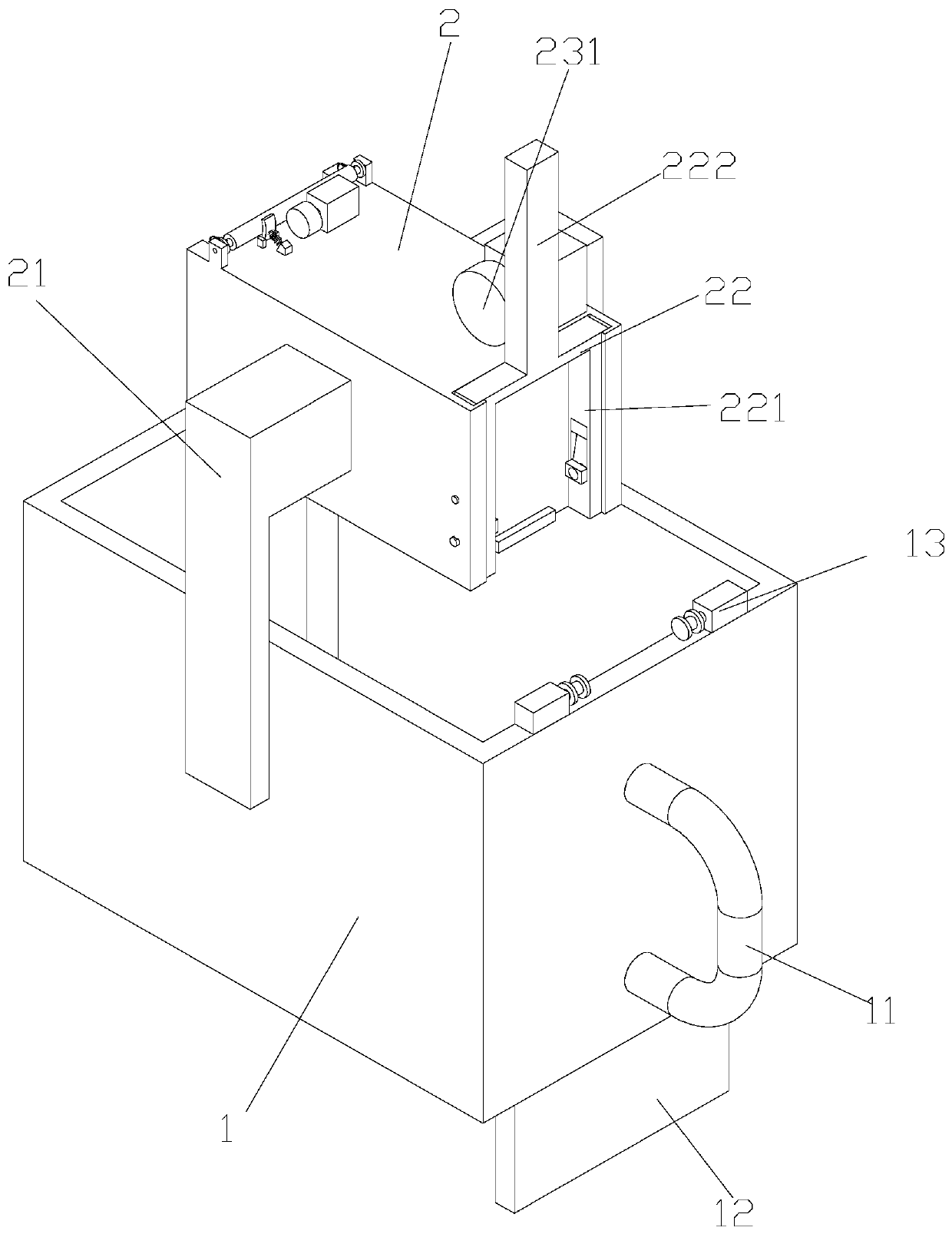

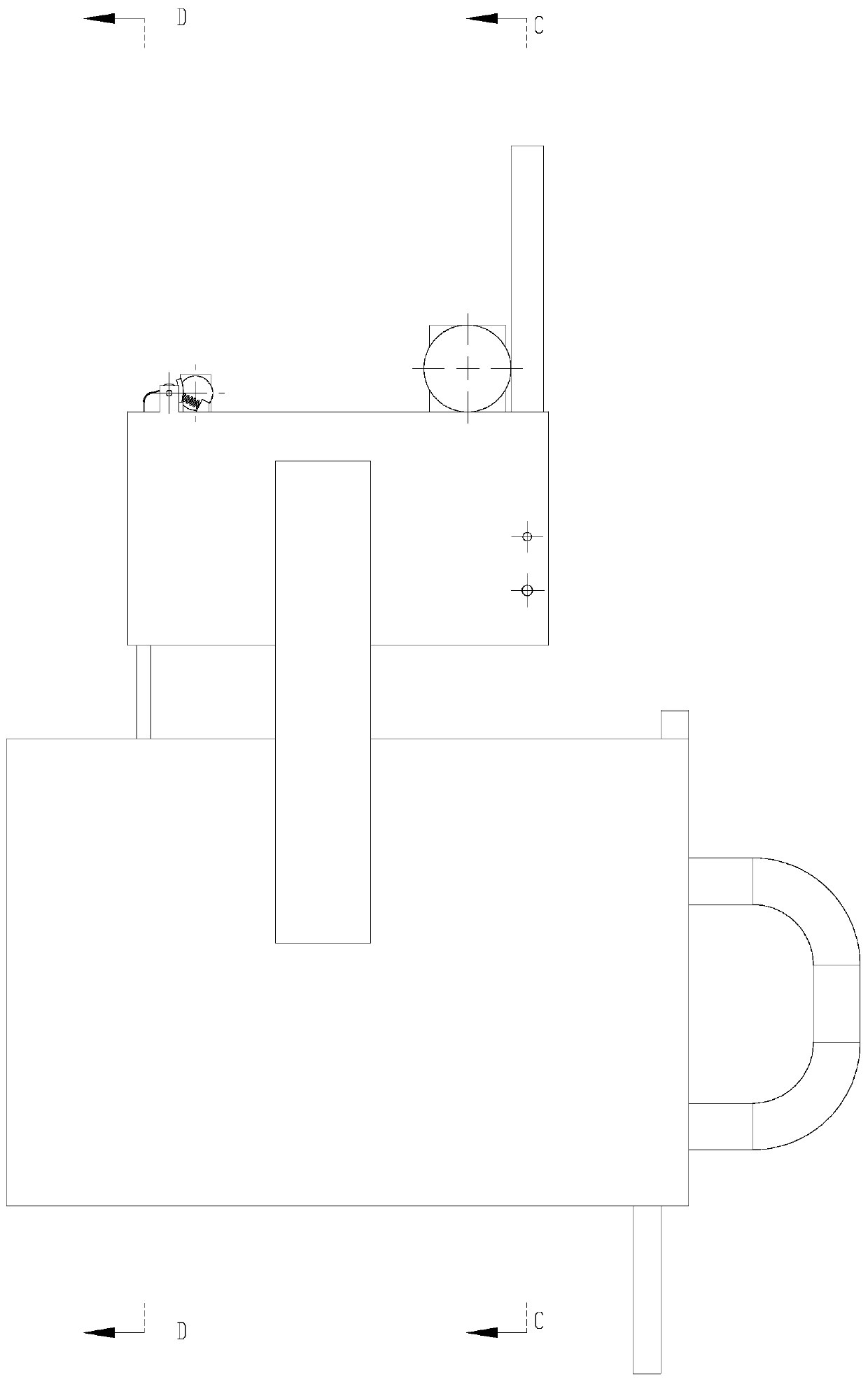

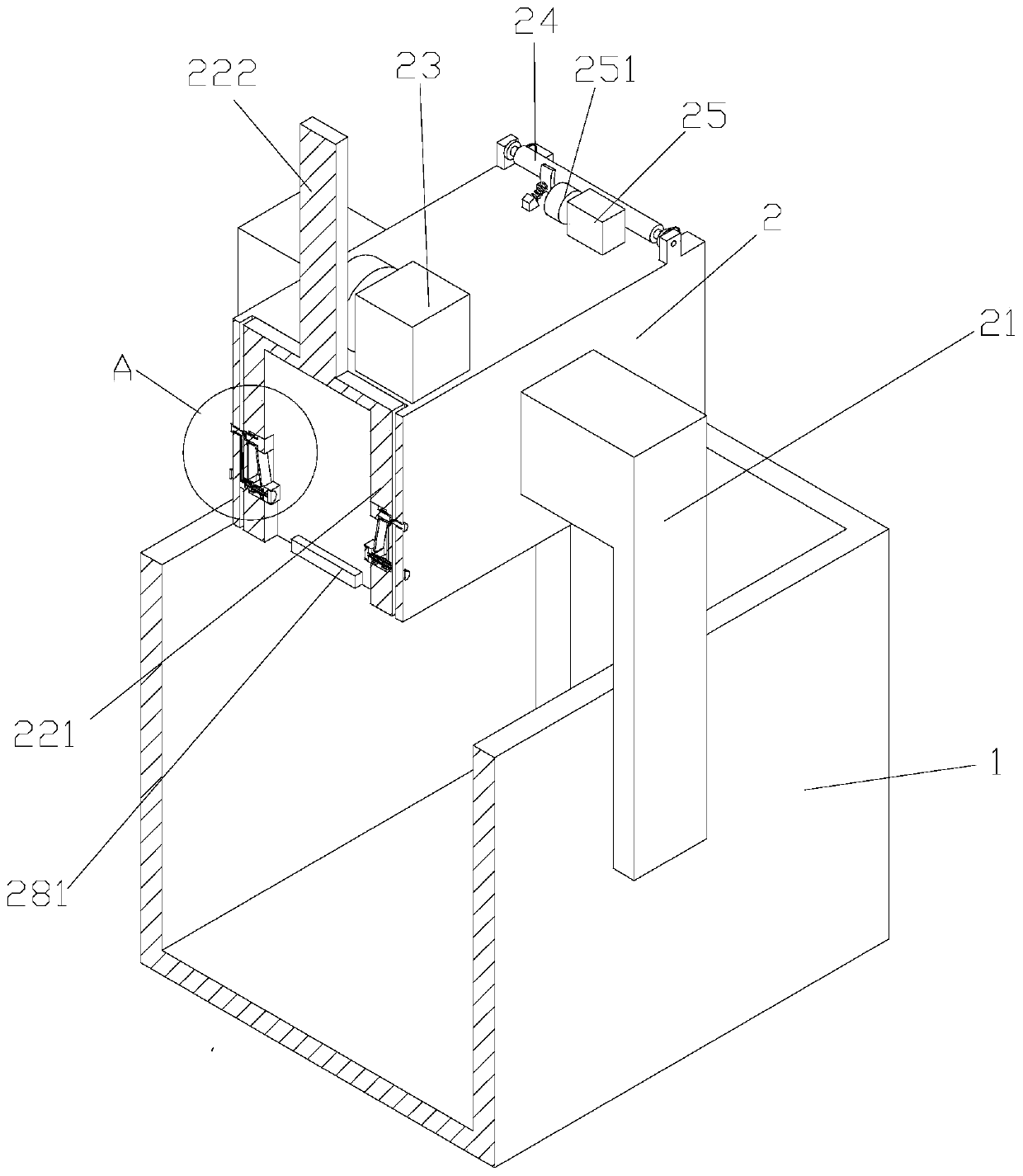

[0040] like Figure 1-25 As shown, a kind of equipment that is used for oxidation treatment of aluminum metal surface comprises electrolytic cell 1 and is arranged on the installation block 2 above described electrolytic cell 1, and described electrolytic cell 1 side wall is provided with first connecting plate 21, so The installation block 2 is arranged on the top of the first connecting plate 21, the installation block 2 is provided with a power supply, the power supply is located in the middle of the installation block, the installation block 2 is provided with a first movable slot, and the first movable A negative plate 3 is provided in the groove, and a second movable groove 28 is arranged on the mounting block 2. The positive and negative electrodes of the power supply are in contact with the inner wall of the second movable groove and the inner wall of the first movable groove respectively, and the second movable groove 28 is in contact with the inner wall of the first m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap