Ultrathin vapor chamber with separated gas and liquid channels

A technology of gas-liquid channels and vapor chambers, applied in electrical components, heat exchange equipment, indirect heat exchangers, etc., can solve the problems of large gas-liquid flow resistance, large contact area, and increased heat transfer resistance of steam chambers. Achieve the effects of reducing flow resistance, reducing heat transfer resistance, and enhancing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

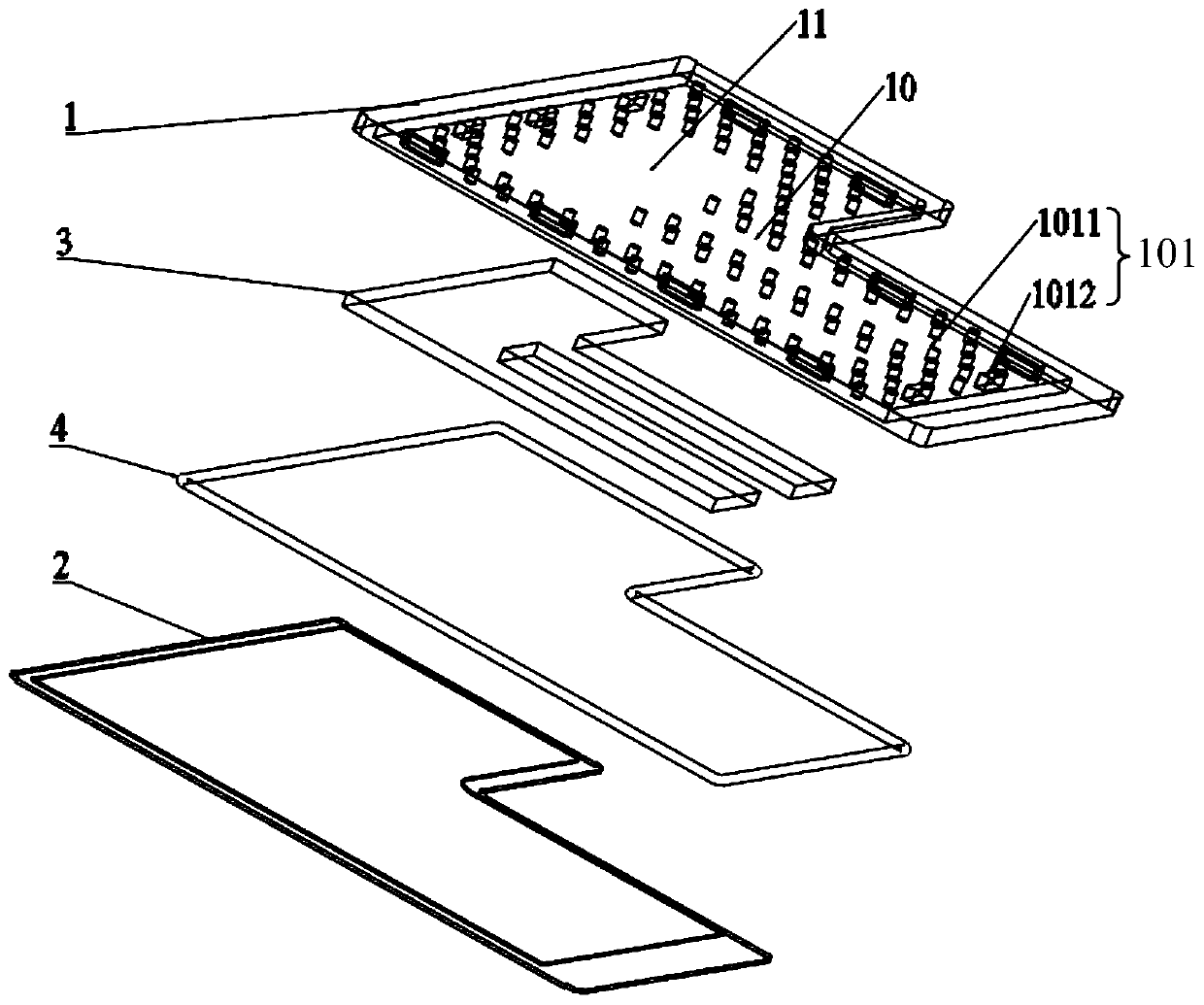

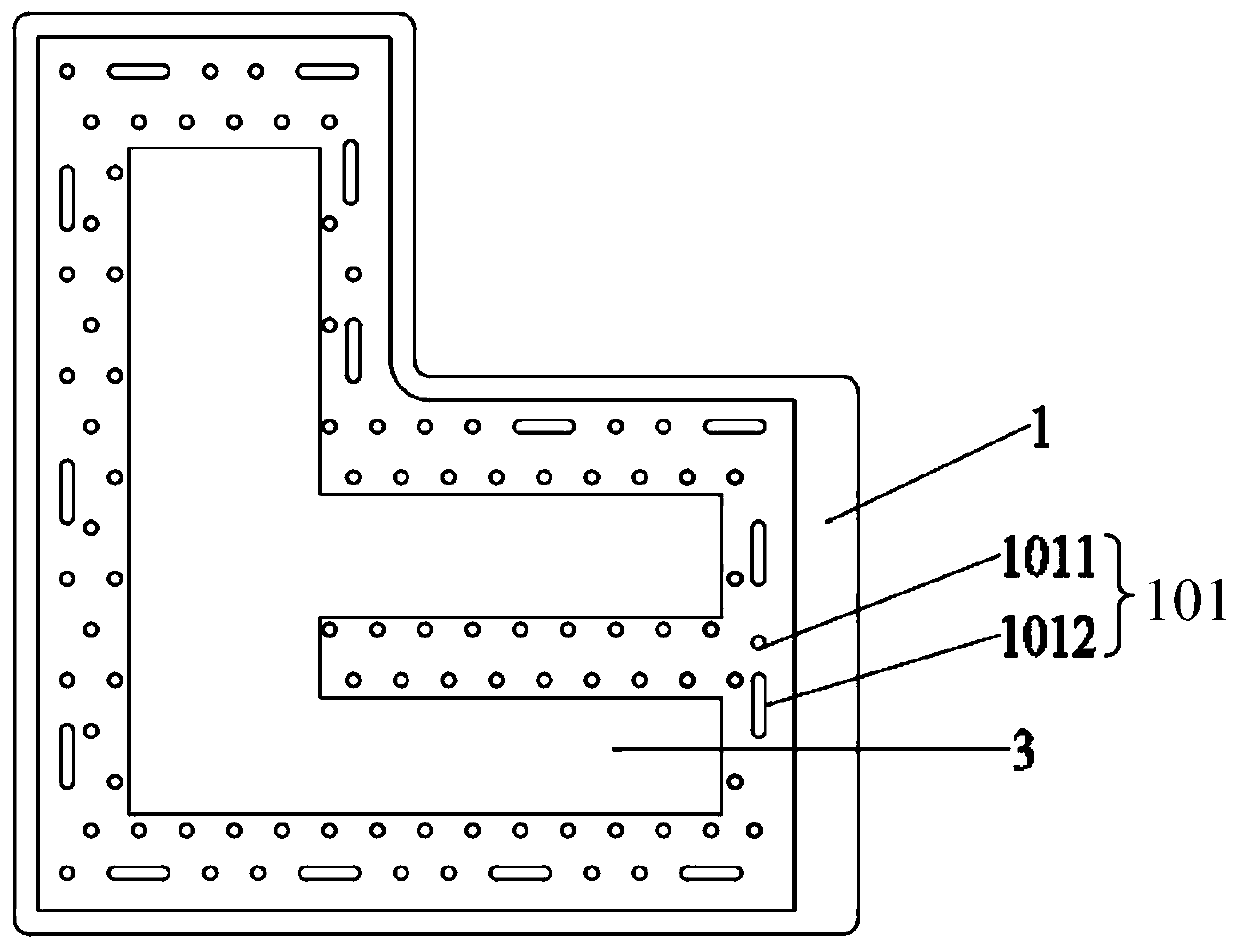

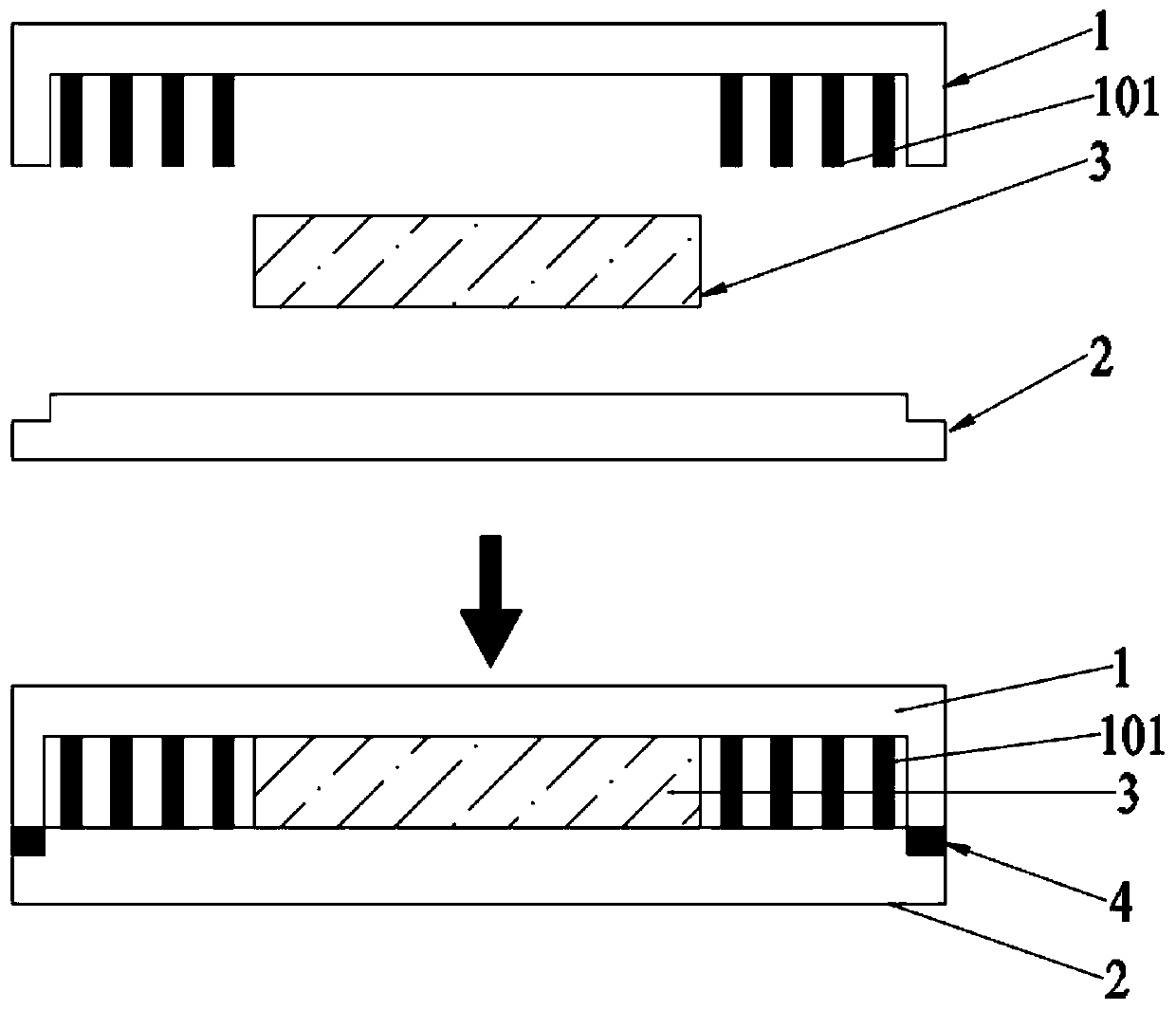

[0030] like Figure 1-2 As shown, an ultra-thin vapor chamber with separated gas-liquid channels includes a cover plate 1 and a bottom plate 2. The periphery of the cover plate 1 and the bottom plate 2 are sealed and connected to form a sealed working medium cavity. The sealed working medium cavity is in a vacuum state. The inside is filled with liquid working medium water, and the inner surface of the cover plate 1 is concave, including a first area 10 and a second area 11, wherein the first area 10 is provided with regularly arranged support columns 101, and the second area 11 is not provided The support column 101 is used to place the foamed copper liquid-absorbing core 3, the upper surface of the foamed copper liquid-absorbing core 3 is closely attached to the lower surface of the cover plate 1, and the lower surface of the foamed copper liquid-absorbing core 3 and the upper surface of the bottom plate 2 Surface fits snugly.

[0031] The wall thickness of the cover plate ...

Embodiment 2

[0038] like Figure 4-5 As shown, an ultra-thin vapor chamber with separated gas-liquid channels includes a cover plate 1 and a bottom plate 2. The periphery of the cover plate 1 and the bottom plate 2 are sealed and connected to form a sealed working medium cavity. The sealed working medium cavity is in a vacuum state. The inside is filled with liquid working medium water, and the inner surface of the cover plate 1 is concave, including a first area 10 and a second area 11, wherein the first area 10 is provided with regularly arranged support columns 101, and the second area 11 is not provided The support column 101 is used to place the foamed copper liquid-absorbing core 3, the upper surface of the foamed copper liquid-absorbing core 3 is closely attached to the lower surface of the cover plate 1, and the lower surface of the foamed copper liquid-absorbing core 3 and the upper surface of the bottom plate 2 Surface fits snugly.

[0039] The wall thickness of the cover plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com