Optical system structure for laser processing

An optical system and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, increased workload of staff, and lack of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

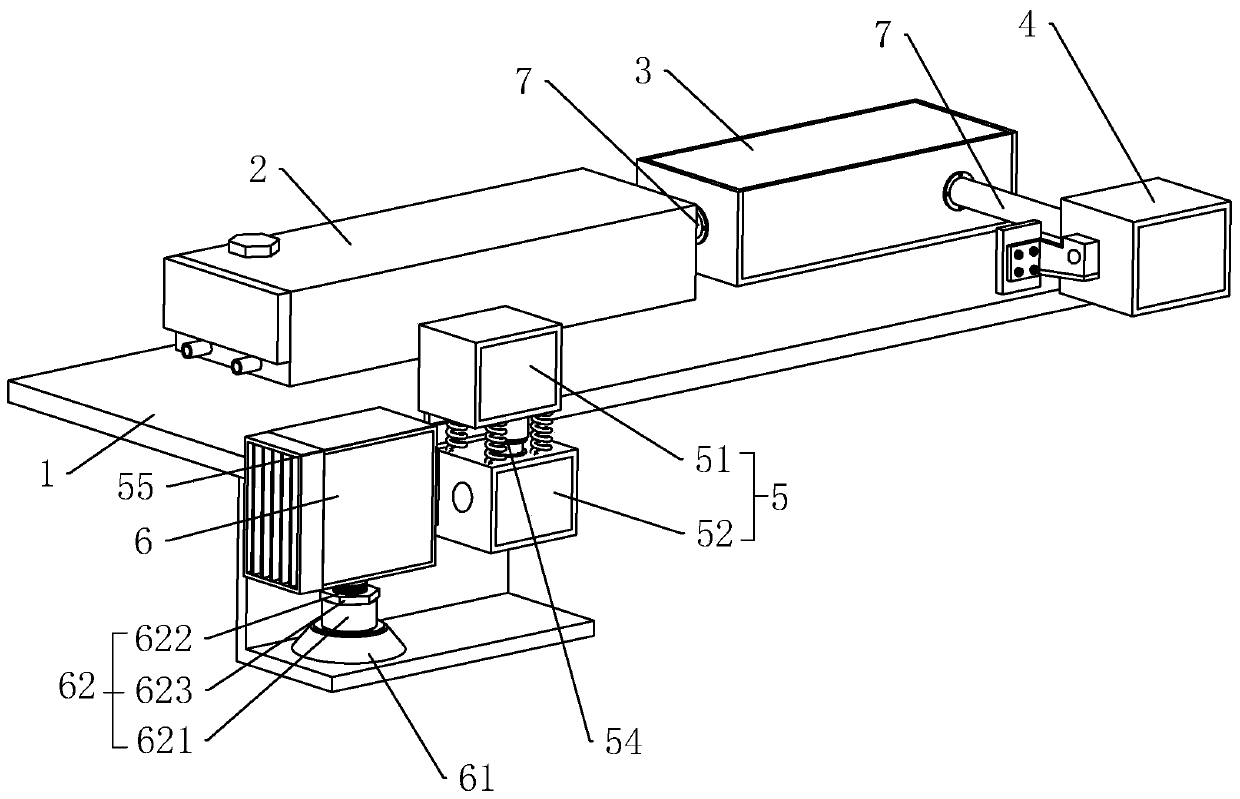

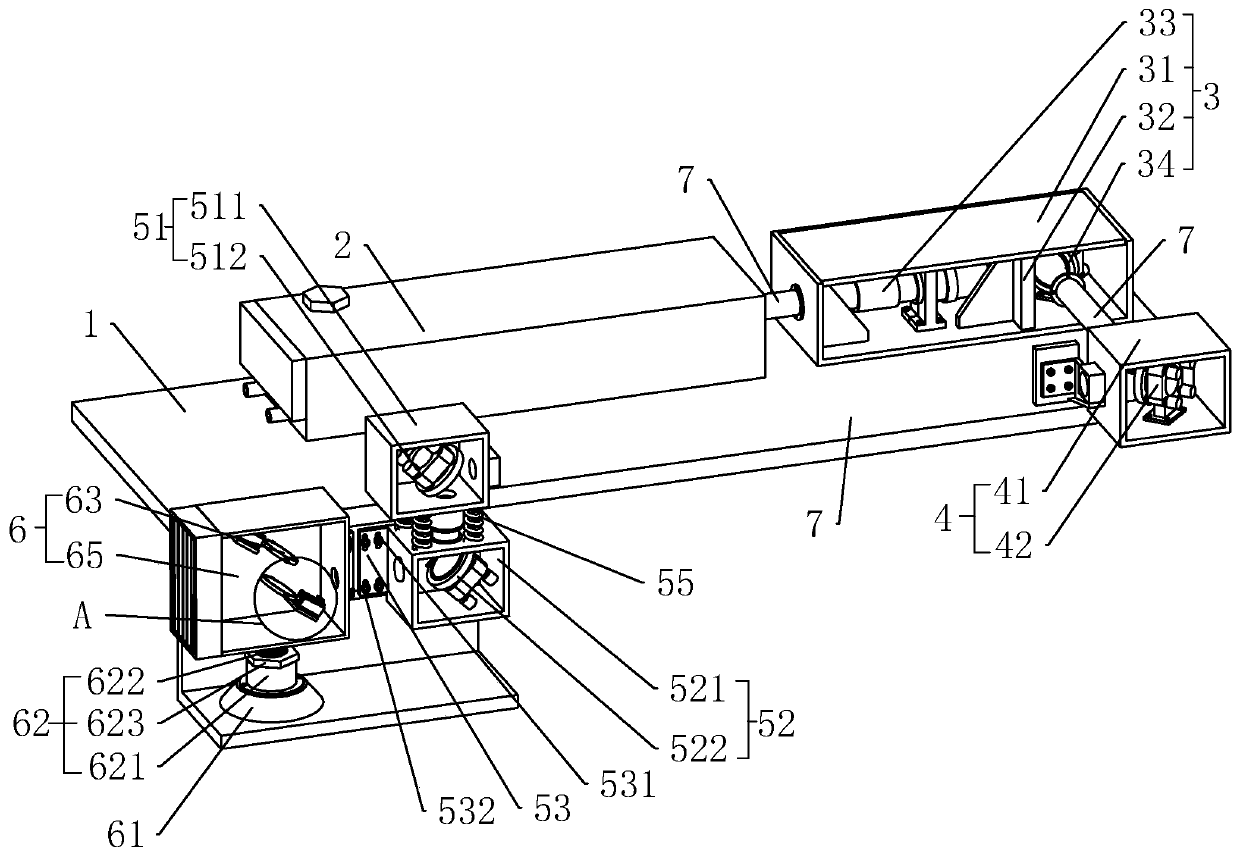

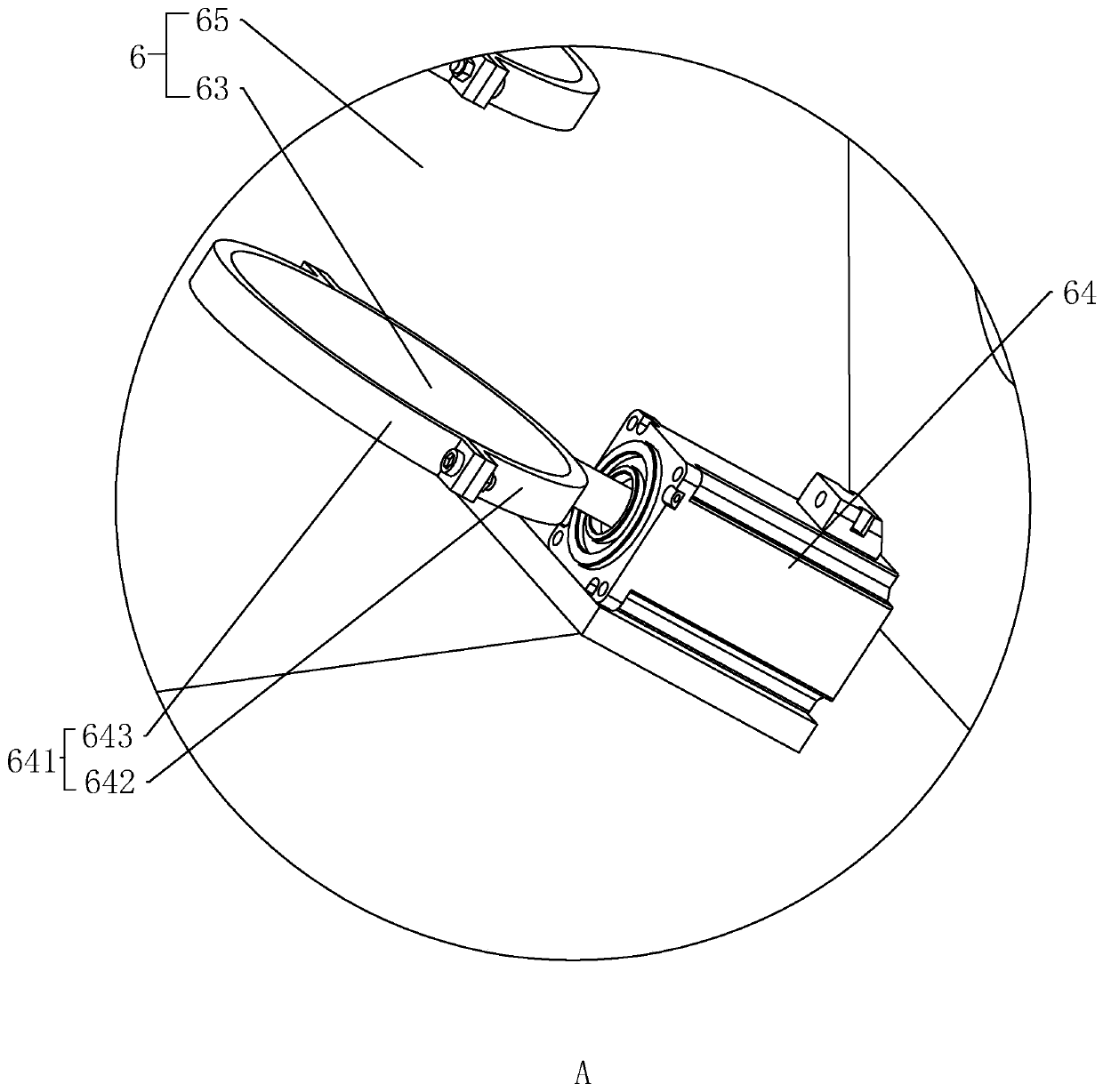

[0048] An optical system structure for laser processing, referring to figure 1 with figure 2 , including a frame 1, on which a laser 2, a beam expander assembly 3 connected to the exit end of the laser 2, a turning assembly 4 connected to the exit end of the beam expander assembly 3, and a turning assembly 4 connected to the exit The reflecting mechanism 5 at the end and the galvanometer assembly 6 connected to the output end of the reflecting mechanism 5, the laser 2 and the beam expander assembly 3, the beam expander assembly and the turning assembly 4 are all connected by a hollow shading rod 7.

[0049] refer to figure 1 with figure 2 , the laser is generated from the laser 2, emitted from the exit end of the laser 2, and enters the beam expander assembly 3 after passing through the light-shielding rod 7. The beam expander assembly 3 includes a box body 1 31 detachably connected to the frame 1 by bolts, The partition plate 32 fixedly connected in the box body one 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com