Guniting material suitable for surface treatment of carboniferous coal mine roadway and preparation method thereof

A surface treatment and shotcrete technology, applied in the field of shotcrete materials for coal mine roadways, can solve problems such as cracking, and achieve the effects of improving adhesion, improving integrity and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

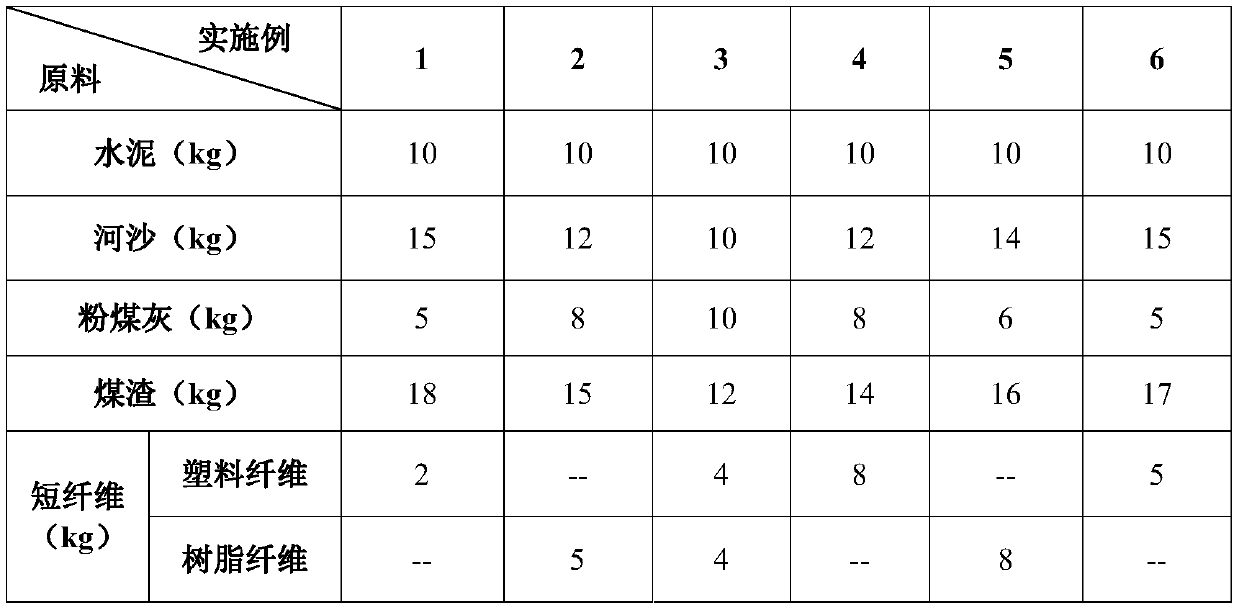

[0025] The present invention provides the raw material ratio tables of Examples 1-6 of the shotcrete materials suitable for the surface treatment of Carboniferous coal mine roadways, as shown in Table 1 below.

[0026] Table 1 is the ratio of the shotcrete material suitable for the surface treatment of the Carboniferous coal mine roadway in Examples 1 to 6 ("--" indicates that it does not contain)

[0027]

[0028] The preparation method of the shotcrete material applicable to the surface treatment of Carboniferous coal mine roadway surface treatment is described in detail below with Example 1, prepare the cement of 10kg, the river sand of 15kg, the fly ash of 5kg, the cinder of 18kg and the plastic fiber of 2kg, Mix the prepared solid raw materials, stir the mixed solid raw materials and water at a mass ratio of 2.5:1, and use manual stirring, then stir for 3 to 5 minutes to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com