Fiber coated with liquid metal and preparation method thereof

A liquid metal and fiber technology, which is applied in the field of liquid metal-wrapped fibers and their preparation, achieves the effects of strong experimental repeatability, controllable size, and low experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0030] A fiber wrapped with liquid metal, which is prepared by a microfluidic chip system, the fiber shell is a polymer, and the liquid metal is wrapped inside; the diameter of the wrapped liquid metal fiber is 100-1000 μm, and the length is 1 cm to 10m.

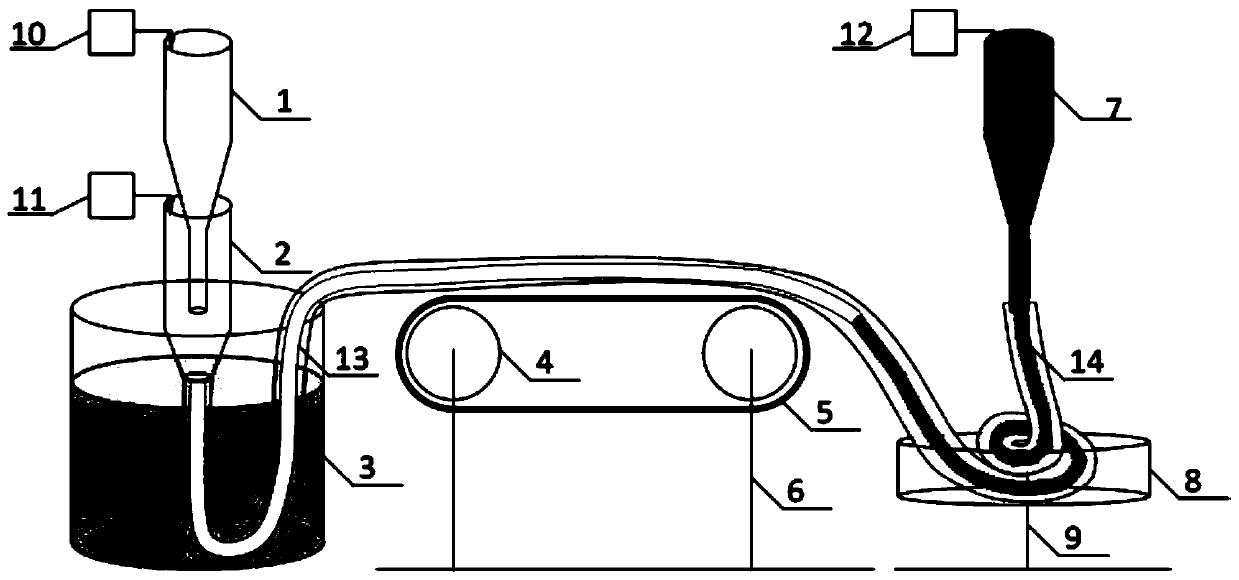

[0031] A microfluidic chip system for wrapping liquid metal fibers, the microfluidic chip system includes a coaxial microfluidic chip, a delivery device and a single-channel microfluidic chip. The coaxial microfluidic chip includes a flow tube A, and a flow tube B is set outside the flow tube A; the single-channel microfluidic chip is composed of a flow tube C; the flow tube A is an aqueous solution The flow pipes, the flow pipe B is a continuous phase channel, the flow pipe C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com