Large-size MEMS vertical comb micro-mirror and preparation method thereof

A comb-tooth micromirror and large-scale technology, which is applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, etc., can solve problems such as low process yield, mirror design structure and manufacturing process limitations, and large chip volume. , to achieve the effect of simple and controllable process, stable process and high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment provides a preparation method of a large-scale MEMS vertical comb micromirror, and realizes the design and manufacture of a large-scale MEMS vertical comb micromirror by using a traditional MEMS process. above, the size, shape and maximum angle of the movable mirror are not limited by the structure and process of the micro-driver, so that the manufacture of a large-size and large-angle movable low-light reflector structure can be realized; in addition, the process is simple and controllable, and the alignment High precision, stable process, suitable for large-scale production, and the shape and thickness of the movable low-light reflector structure can be flexibly selected according to design requirements, with high flexibility and wider application range.

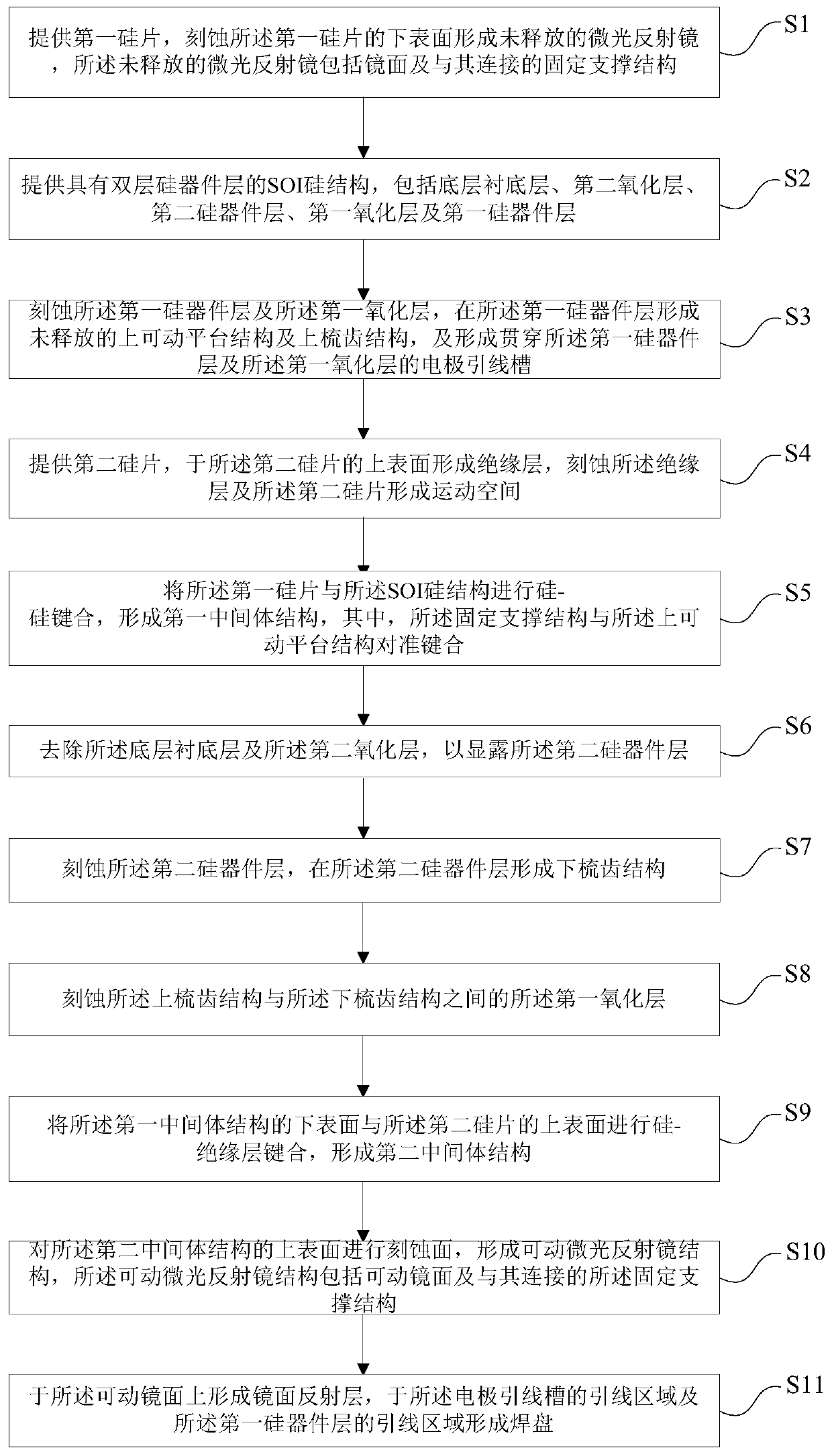

[0078] Such as Figure 1 to Figure 19 Shown, described preparation method comprises the steps:

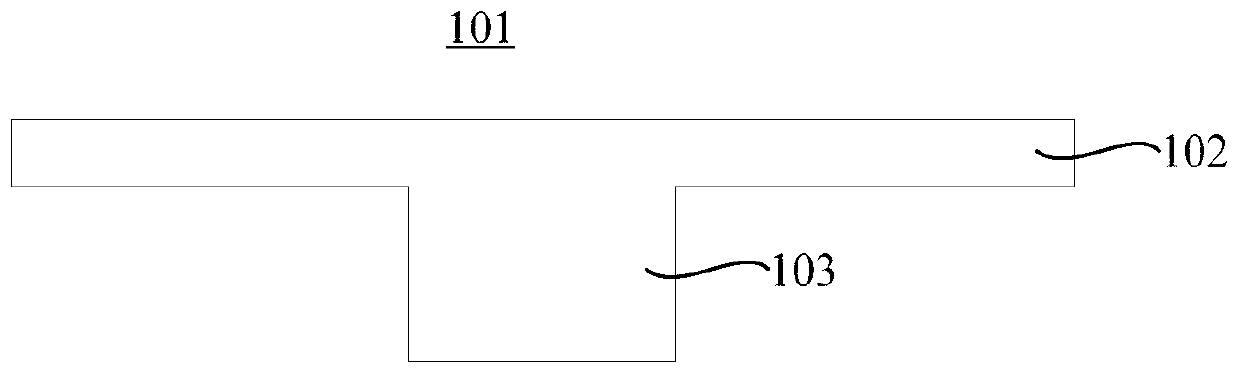

[0079] Such as Figure 1 to Figure 4 As shown, step S1 is first performed to provide a first silicon...

Embodiment 2

[0115] This embodiment provides a large-scale MEMS vertical comb micromirror, the large-scale MEMS vertical comb micromirror structure can be prepared by the preparation method of the first embodiment, but not limited to the preparation method described in the first embodiment, as long as it can Just form this structure. For the beneficial effects that the large-size MEMS vertical comb micromirror can achieve, please refer to Embodiment 1, which will not be repeated below.

[0116] Such as Figure 20 As shown, the large-scale MEMS vertical comb micromirror includes:

[0117] The movable low-light mirror structure 303 includes a movable mirror surface 304 and the fixed support structure 103 connected thereto;

[0118] a movable platform structure 601 located below the movable low-light reflector structure 303, and bonded to the fixed support structure 103;

[0119] The upper comb structure 207 and the lower comb structure 209 arranged on the outside of the movable platform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com