Experiment table and experiment method for simulating conveying and laying of propping agent in reservoir fracturing fracture

A technology for simulating reservoirs and proppants, applied in 3D modeling, earthwork drilling, 2D image generation, etc., it can solve the problems such as the initiation and closure of fracturing fractures that cannot be simulated repeatedly, and achieve the effect of ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

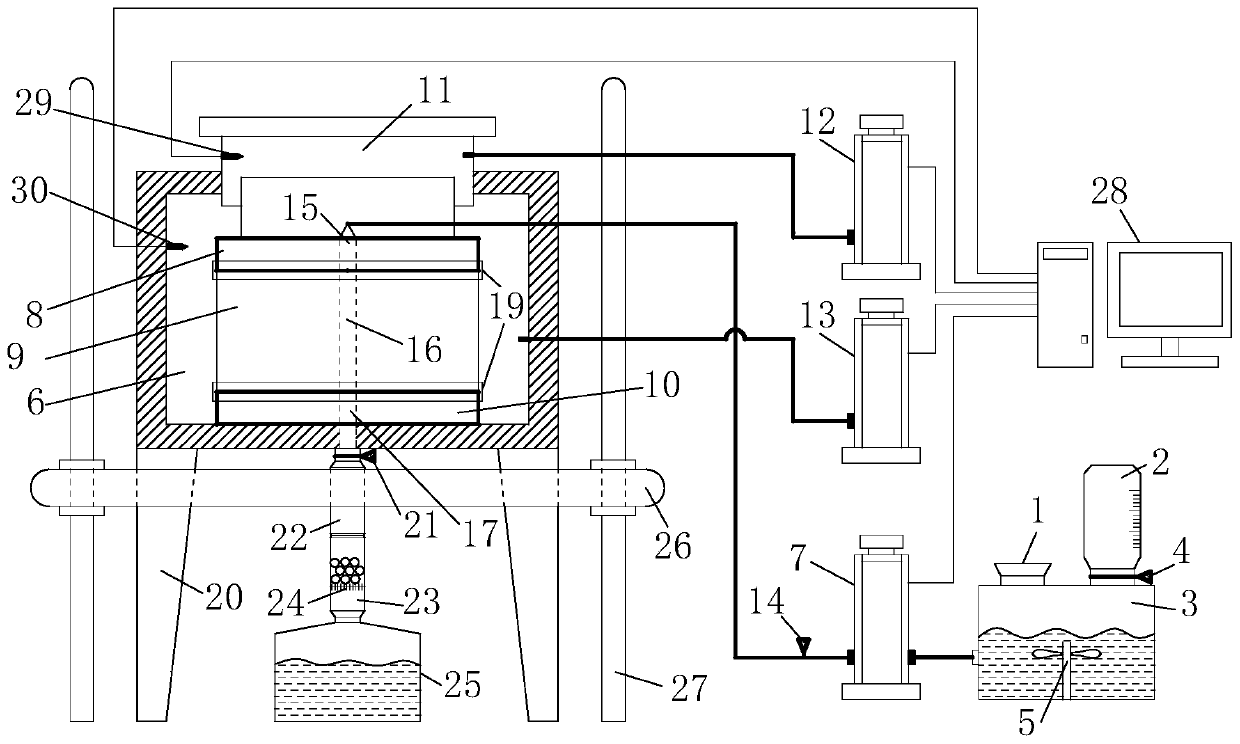

[0045] Such as figure 1 As shown, an experimental platform for simulating proppant delivery and laying in reservoir fracturing fractures, including sand-carrying fluid preparation part, reservoir fracturing simulation part, sand-carrying fluid recovery part, scanning imaging part, control and data monitoring part.

[0046] Specifically:

[0047] The preparation part of the sand-carrying fluid mixes the proppant particles and the fracturing fluid to prepare the sand-carrying fluid. Open a sand inlet 1, the liquid storage tank 2 is placed upside down above the mixing box 3, the electric agitator 5 is installed inside the mixing box 3, proppant particles are added to the mixing box 3 through the sand inlet 1, and the liquid storage is opened The No. 1 valve 4 installed at the connection between the tank 2 and the mixing tank 3 can inject the fracturing fluid into the mixing tank 3, and mix the fracturing fluid and proppant to obtain the sand-carrying fluid for use.

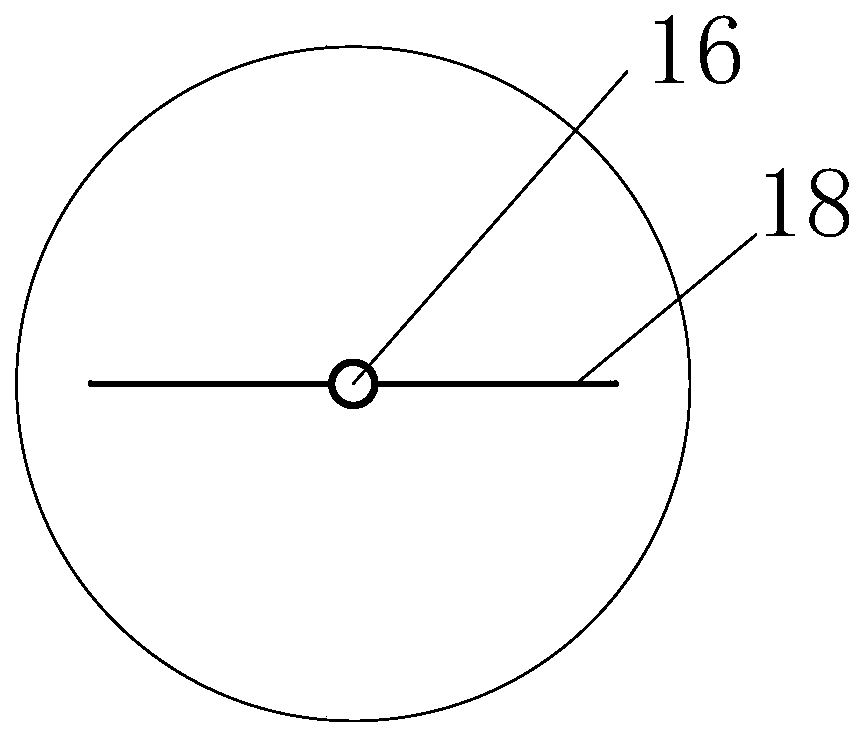

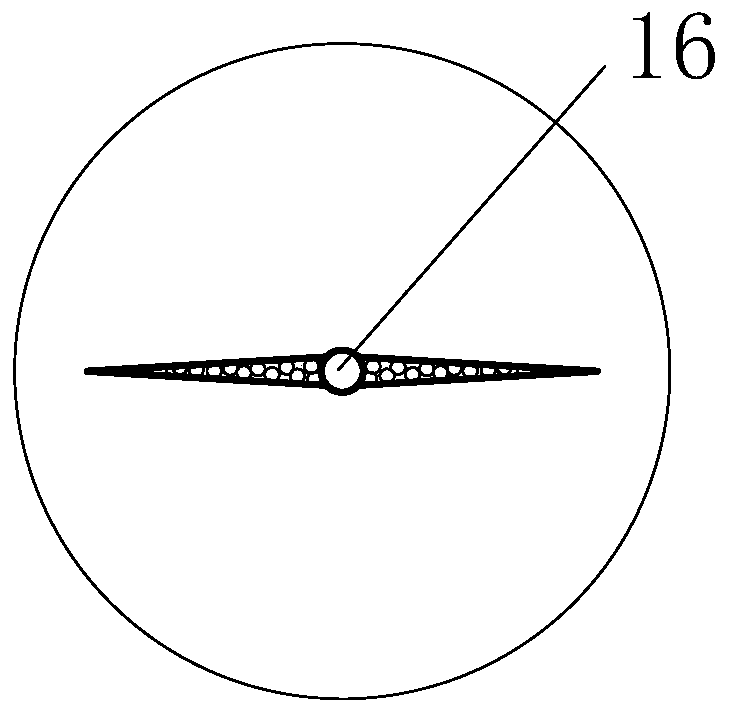

[0048] Th...

Embodiment 2

[0058] The invention discloses an experimental method for simulating proppant delivery and laying in reservoir fracturing fractures, using the test bench in Example 1, specifically comprising the following steps:

[0059] Step 1. Stress loading

[0060] The computer 28 controls the axial hydraulic pump 12 to inject hydraulic oil into the axial hydraulic cylinder 11 through the high-pressure pipe, controls the horizontal hydraulic pump 13 to inject hydraulic oil into the injection pressure chamber 6, and loads the axial stress of the reservoir model 9 to 15 MPa, The horizontal stress is loaded to 5MPa.

[0061] Step 2. Preparation of sand-carrying fluid

[0062] Open No. 1 valve 4, inject the 2L fracturing fluid sample pre-stored in the liquid storage tank 2 into the mixing tank 3, and add 600g of proppant from the sand inlet 1 to the mixing tank 3 according to the concentration meter of 300g / L Granules, start the electric agitator 5 inside the mixing tank 3, stir and mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com