Hard X-ray and photoelectron shielding composite material

A composite material and X-ray technology, which is applied in the field of hard X-ray and optoelectronic shielding composite materials, can solve the problems of poor shielding performance of hard X-rays, achieve poor shielding performance, excellent mechanical properties, and reduce the impact of optoelectronics on electronic equipment. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

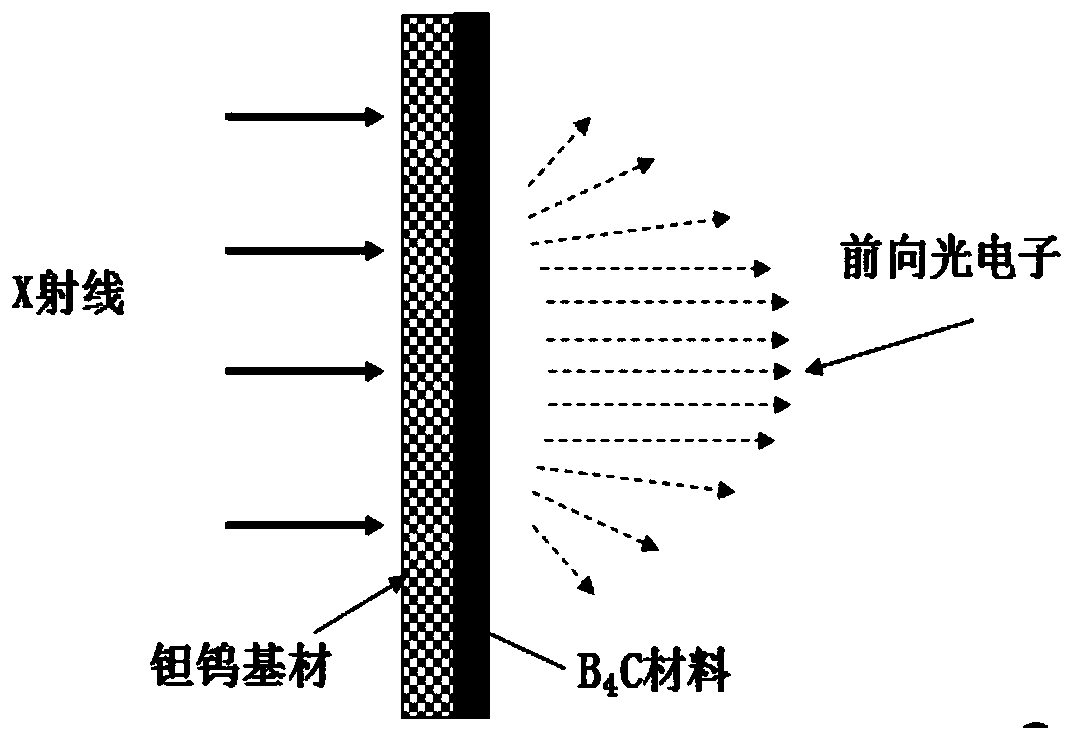

[0042] Such as figure 1 As shown, a kind of hard X-ray and optoelectronic shielding composite material comprises an X-ray shielding layer and a photoelectron shielding layer, the single side of the X-ray shielding layer is provided with an optoelectronic shielding layer, and the X-ray shielding layer is made of TaW alloy, The optoelectronic shielding layer adopts B 4 C is made, the thickness of the TaW alloy is 0.3mm, the B 4 The thickness of C is 50 μm, wherein, the mass fraction of TaW alloy W is 10%, and the mass fraction of Ta is 90%.

[0043] In this embodiment, the surface density of the TaW alloy is 0.5061g / cm 2 , the bulk density is 16.87g / cm 3 , the thermal conductivity is 47W / (m×K), and the thermal expansion coefficient is 5×10 -6 / K, tensile strength R m 830MPa, yield strength R p0.2 840MPa, the elongation A is 10%; the B 4 The thermal conductivity of C is 0.68~0.9W / (m×K), and the thermal expansion coefficient is 3.56×10 -6 / K(0~100℃)

[0044] The shield...

Embodiment 2

[0047] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0048] The thickness of the TaW alloy is 0.5mm, the B 4 C has a thickness of 100 μm.

[0049] In this embodiment, the surface density of the TaW alloy is 0.8435g / cm 2 , the bulk density is 16.87g / cm 3 , the thermal conductivity is 47W / (m×K), and the thermal expansion coefficient is 5×10 -6 / K, tensile strength R m 830MPa, yield strength R p0.2 840MPa, the elongation A is 10%; the B 4 The thermal conductivity of C is 0.68~0.9W / (m×K), and the thermal expansion coefficient is 3.56×10 -6 / K(0~100℃).

[0050] The cross-sectional morphology of the shielding composite material of this embodiment is as follows Figure 5 shown.

[0051] The shielding effect of the present embodiment:

[0052] 0.5mmTaW10 shields 94% of X-rays with 60KeV energy and 99% of 40KeV X-rays; 100μmB 4 C shields 91% of optoelectronics below 100KeV.

Embodiment 3

[0054] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0055] The thickness of the TaW alloy is 0.4mm, the B 4 C has a thickness of 80 μm.

[0056] In this embodiment, the surface density of the TaW alloy is 0.6748g / cm 2 , with a bulk density of 16.87g / cm 3 , the thermal conductivity is 47W / (m×K), and the thermal expansion coefficient is 5×10 -6 / K, tensile strength R m 830MPa, yield strength R p0.2 840MPa, the elongation A is 10%; the B 4 The thermal conductivity of C is 0.68~0.9W / (m×K), and the thermal expansion coefficient is 3.56×10 -6 / K(0~100℃)

[0057] The shielding effect of the present embodiment:

[0058] 0.4mmTaW10 shields 90% of X-rays with 60KeV energy and 99% of 40KeV X-rays; 80μmB 4 C shields 85% of optoelectronics below 100KeV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com