Self-gel-breaking fiber fracturing fluid as well as preparation method and application thereof

A fracturing fluid and fiber technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as the influence of fracturing effect, reduce the volume of fracturing fluid reformation, etc., so as to shorten the fracturing construction period and improve the pressure The effect of cracking, expanding the transformation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

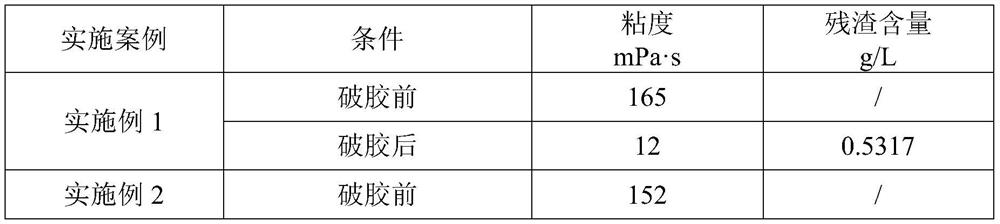

Examples

Embodiment 1

[0036] This embodiment provides a self-breaking fiber compactment, wherein the self-breaking fiber compactment is prepared by means of a method comprising the specific step:

[0037] 300 ml of deionized water was added to the high mixture, and 3 g of potassium formate, 0.06 g of the capsule type breakage and 3 g of degradable fibers were added to the high mixture, and the base fluid was obtained after stirring for 20 minutes.

[0038] Further, a 0.3 g of Gemini quaternary ammonium salt viscoelastic surfactant produced by 0.3 g of Henan Road Pure Chemical Technology Co., Ltd. was added, and the high-speed stirrer was stirred at 11000 r / min for 10 min Since the self-breaking fibers;

[0039] Among them, the capsule type breakage of the capsule ingredients are chitosan produced by Shandong Aokang Biotechnology Co., Ltd., and the capsule is potassium permanganate;

[0040] The degradable fiber is a polylactic acid fiber having a molecular weight produced by Wuhan Yisheng Biotechnolo...

Embodiment 2

[0042] This embodiment provides a self-breaking fiber compactment, wherein the self-breaking fiber compactment is prepared by means of a method comprising the specific step:

[0043] 300 ml of deionized water was added to the high mixture, and 4 g of potassium formate, 0.09 g of the capsule type breakage and 4 g of degradable fibers were added to the high mixture, and the base fluid was obtained after stirring for 20 minutes.

[0044] Further, 0.5 g of 0.5 g of a polysaccharide viscoelastic surfactant formed of sodium hexaalkyl sulfonate and hydroxyethyl cellulose is added, and the mixer is stirred at 11000 r / min at a rotational speed of 11000 r / min for 10 min. The self-detergent fiber compact is made;

[0045] Among them, the capsule type breakage of the capsule ingredients are chitosan produced by Shandong Aokang Biotechnology Co., Ltd., and the capsule is potassium permanganate;

[0046] The degradable fiber is a medium-high viscosity polycarbonate fiber having a molecular we...

Embodiment 3

[0048] This embodiment provides a self-breaking fiber compactment, wherein the self-breaking fiber compactment is prepared by means of a method comprising the specific step:

[0049] 300 ml of deionized water was added to the high mixture, and 6.0 g of potassium formate, 0.09 g of a capsule type breakage agent and 4.5 g of degradable fibers were added to the high stirup, and the base fluid was obtained after stirring for 20 minutes.

[0050] Further, 0.6 g of the oleo-propyl dimethylamine tertiary amine nonionic surfactant produced by Shanghai Silong New Material Technology Co., Ltd. was added to the base liquid, and the mixer was stirred at 11000 R / min at a rotational speed of 11000 R / min after 10min. Advantages of the self-breaking fiber fracture;

[0051] Among them, the capsule type breakder's cystic content is a poly beta-hydroxybutyrate (Sichuan Zhizheng Technology Co., Ltd.), and the capsule is potassium sulfate;

[0052] The degradable fiber is a polylactic acid fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com