Intelligent maintenance and overhaul control system and method for dust remover

A technology for intelligent maintenance and control systems, applied in general control systems, control/regulation systems, chemical instruments and methods, etc., can solve the problems of decreased efficiency, low efficiency, and low automation level of dust collectors, and reduce large-scale equipment failures. The number of times, the number of times to avoid major equipment failures, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

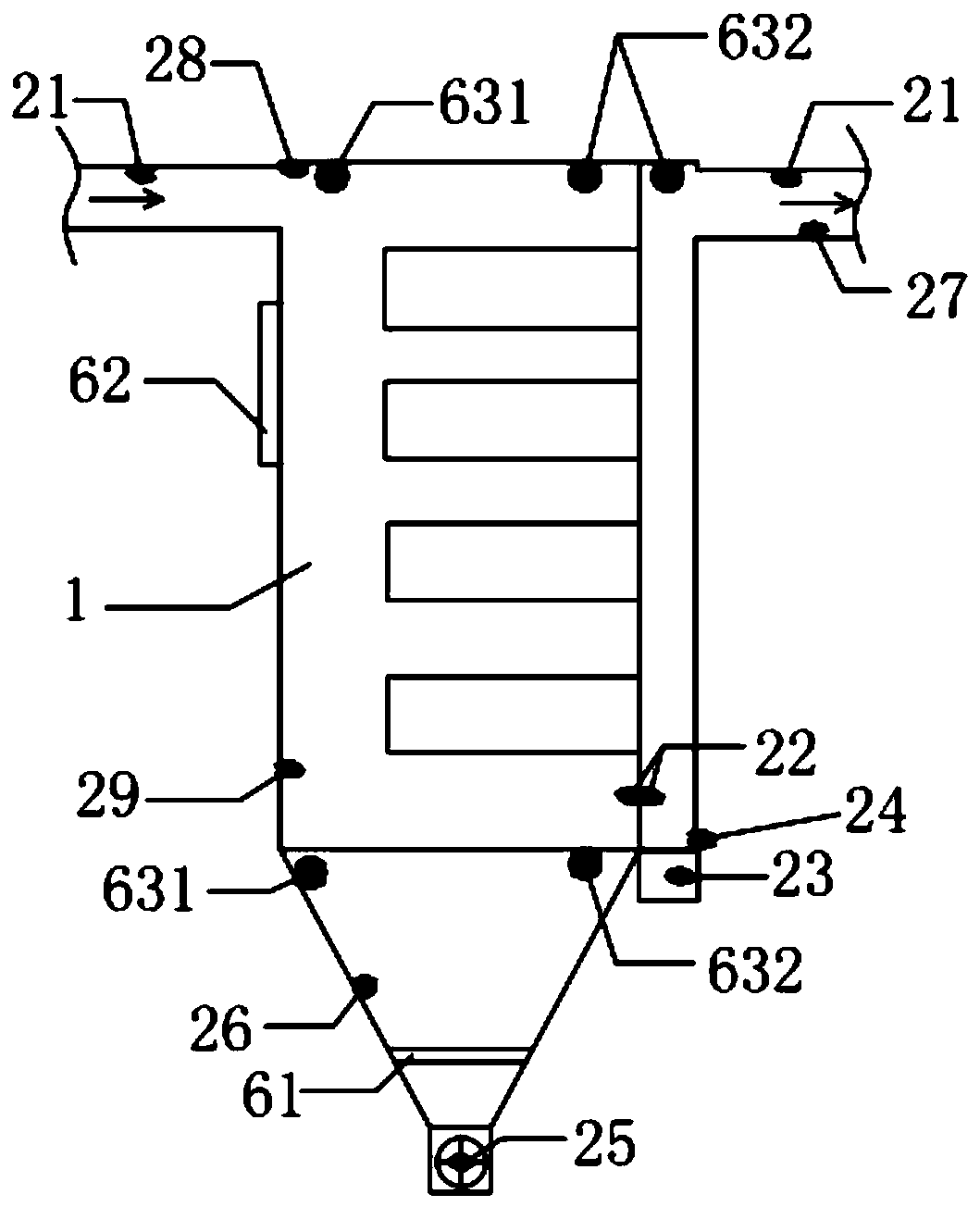

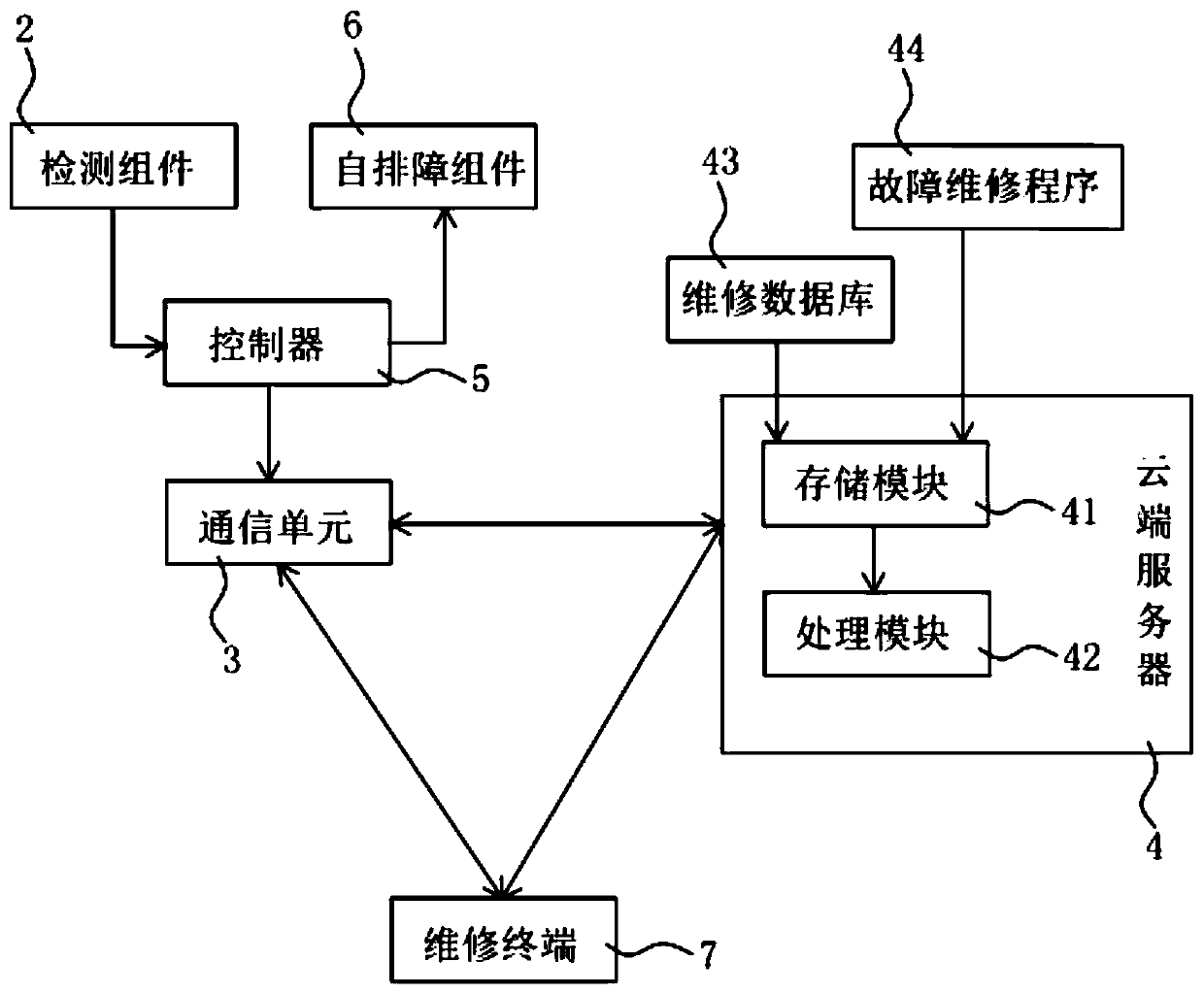

[0029] Example: such as figure 1 and figure 2 As shown, an intelligent maintenance and overhaul control system for a dust collector includes: a dust collector body 1, a detection component 2, a communication unit 3, a cloud server 4, and a controller 5; and a self-removal component 6; the detection component 2 includes a dust collector Inlet and outlet pressure difference detector 21, dust collector pressure difference detector for detecting filtered air and dust collector outlet 22, pressure detection probe 23 at the compressed air cylinder, pulse valve work detector 24, ash discharge valve rotation Detector 25, ash hopper material level detector 26 and dust collector broken bag detection probe 27; controller 5 is used to receive the real-time detection data of detection component 2 and the running state of dust collector body 1, and control self-defeating component 6 and The components of dust collector body 1 work.

[0030] The communication unit 3 is used to send the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com