High-strength reflective coating preparation equipment

A reflective paint, high-strength technology, applied in reflective/signal paints, coatings, methods of granulating raw materials, etc., can solve the problems of difficult to evenly distribute reflective particles, poor road reflective effect, poor fluidity, etc. tiled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

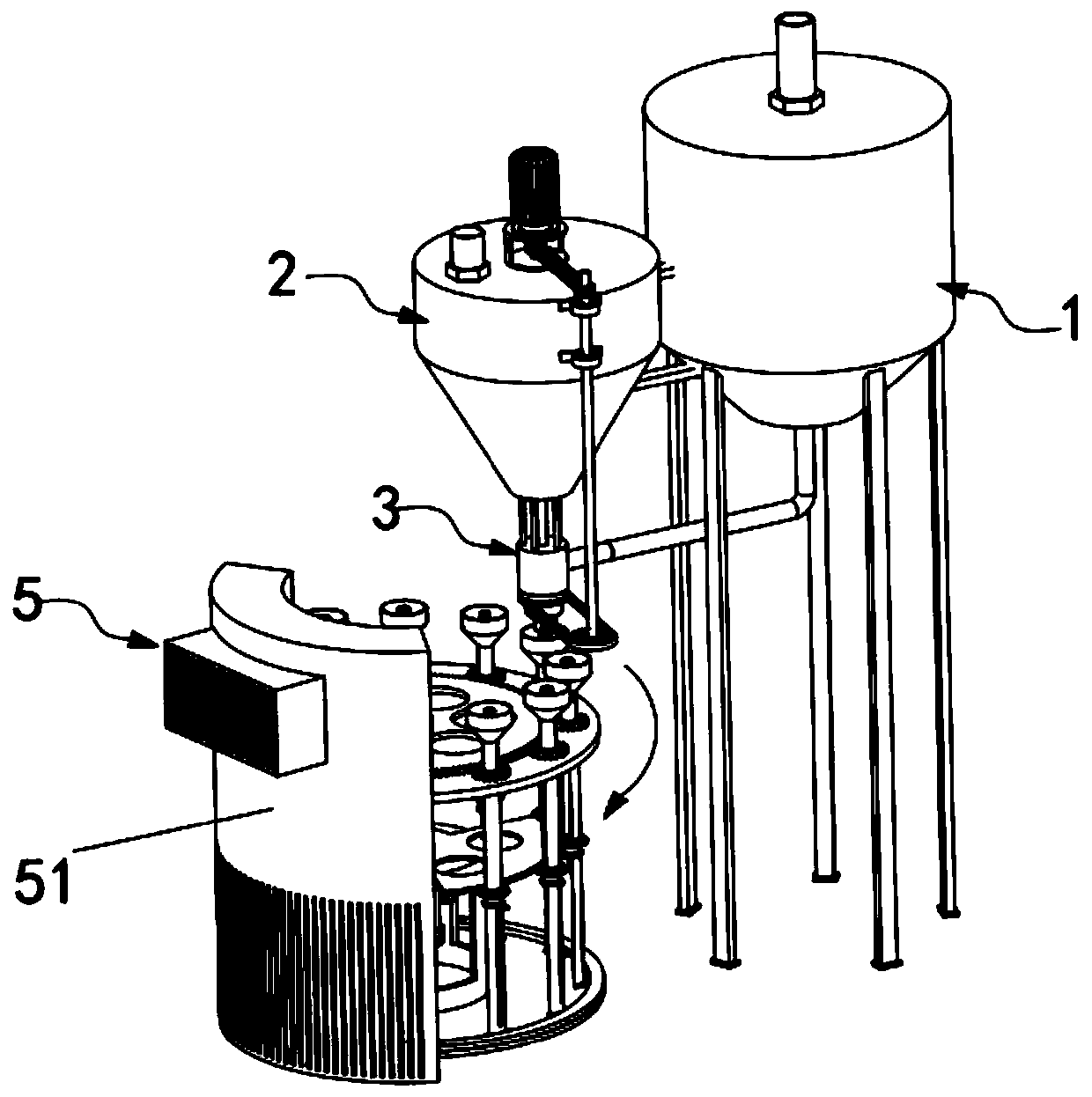

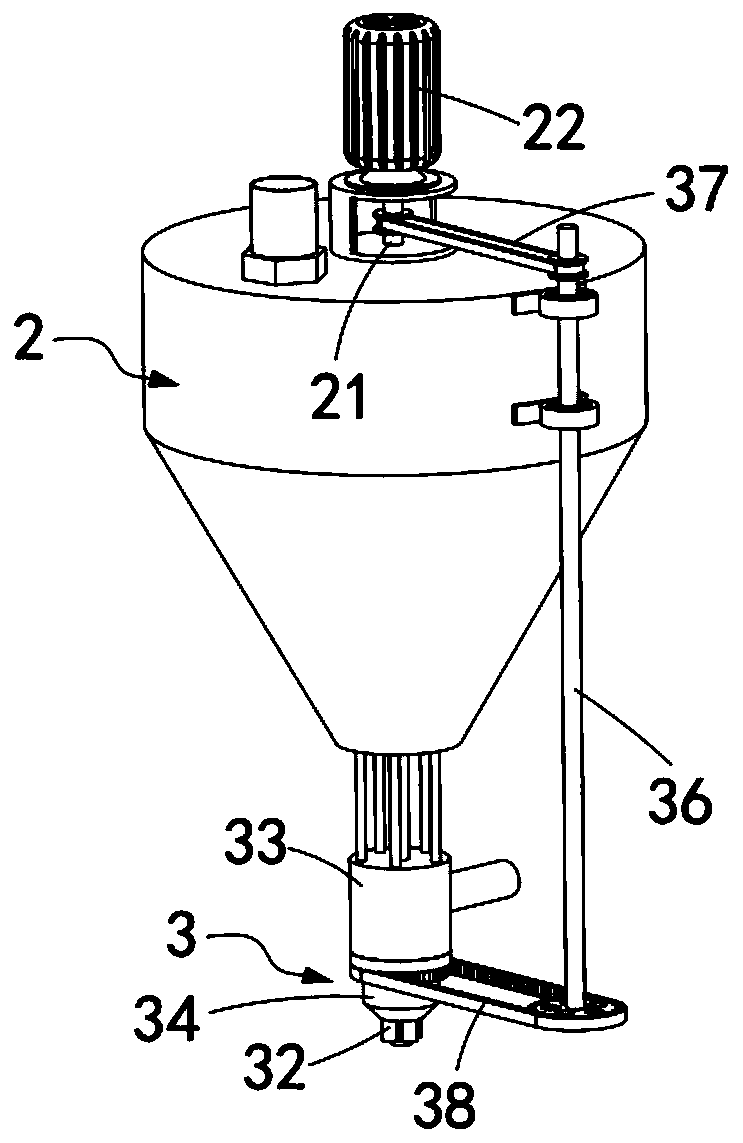

[0051] Such as Figure 1 to Figure 7 As shown, a high-strength reflective paint preparation equipment includes a paint raw material warehouse 1 and a glass bead raw material warehouse 2, and also includes:

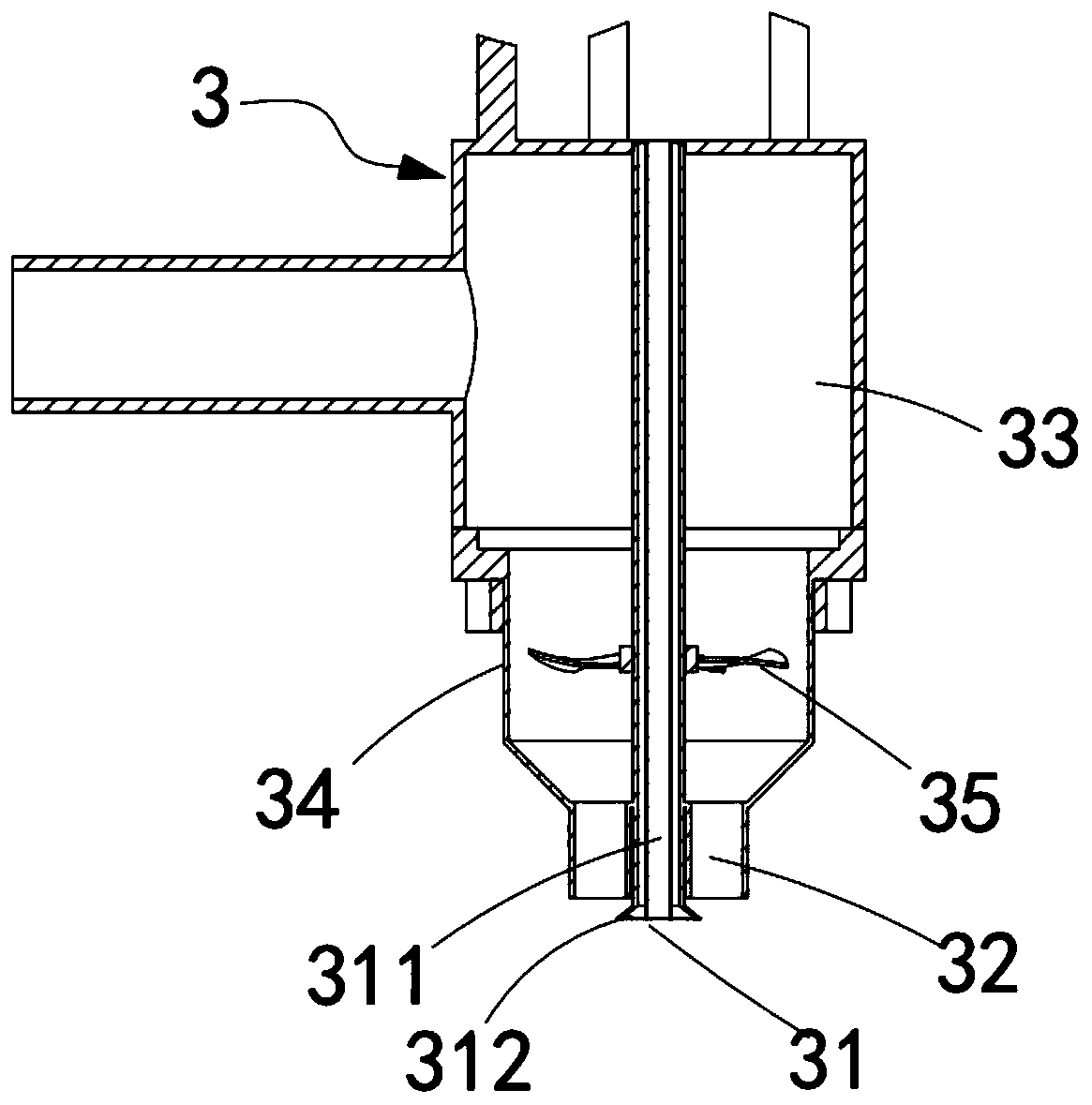

[0052] The discharge mechanism 3, the discharge mechanism 3 is connected and arranged directly below the glass bead raw material warehouse 2, and it includes a glass bead discharge head 31 and a number of paint discharge materials surrounding the glass bead discharge head 31. head 32, the glass bead discharge head 31 communicates with the glass bead raw material warehouse 2, and its discharge end includes a circular inner discharge channel 311 and an annular outer discharge channel 312, and the outer discharge channel 312 surrounds the An inner discharge channel 311 is provided, the paint discharge head 32 communicates with the paint raw material bin 1, and revolves around the glass bead discharge head 31;

[0053] Mixing and molding mechanism 4, the mixing and molding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com