Knife handle automatic clamping mechanism

A technology of clamping mechanism and tool handle, which is applied in the direction of clamping, metal processing machinery parts, support, etc., can solve the problems of low automation efficiency and unfavorable promotion of CNC machining centers, etc., and achieve precise automatic positioning and reliable clamping of tool handles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the technical solution clearer, the technical solution will be further described in detail below in conjunction with specific embodiments. It should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the technical solution.

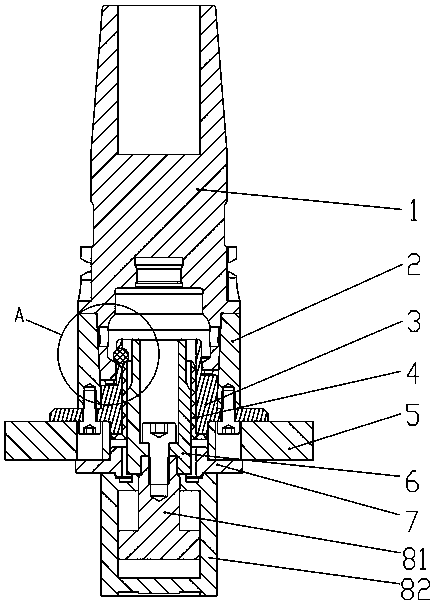

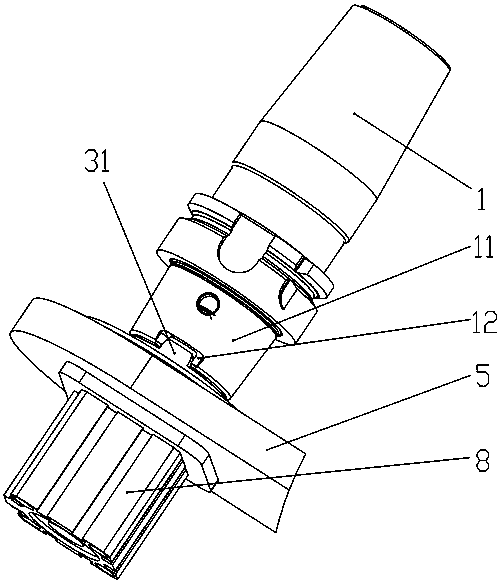

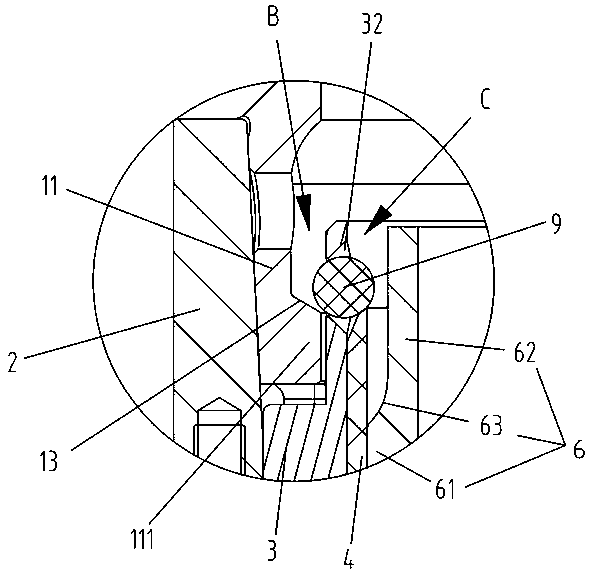

[0034] Such as Figure 1-Figure 3 As shown, the knife handle automatic clamping mechanism proposed in this embodiment includes a knife handle 1, a knife seat 2, a knife seat inner bushing 3, a lifting column 6, a cylinder 8 and a locking steel ball 9, wherein the tail end of the knife handle 1 It is cylindrical, and the tail end of the handle 1 extends toward the axial direction of the handle 1 to form a ring-shaped inner edge structure 111. The end surface of the inner edge structure 111 facing the head side of the handle 1 is an inner slope 13 of the handle. The tail end of the knife handle 1 has a knife handle limit groove 12 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com