Device and method for circumferential strengthening of polylactic acid pipe

A strengthening device and polylactic acid technology, applied in the direction of tubular objects, household appliances, and other household appliances, can solve the problems of prone to radial retraction, tube wall thickness cannot be precisely controlled, and prone to axial retraction, etc., to achieve Achieve precise temperature control, precise inner and outer diameters, and good wall thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

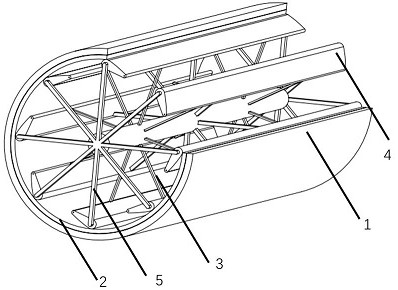

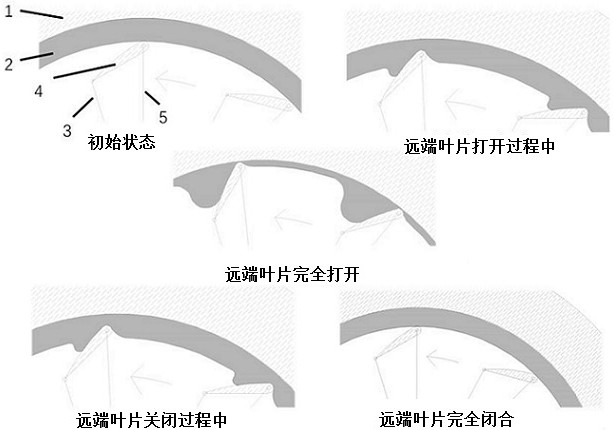

[0035] like figure 1 , figure 2 and image 3 As shown, put the polylactic acid pipe 2 to be strengthened into the metal mold 1, the wall thickness of the polylactic acid pipe 2 is 50-100um, heat the metal mold 1 to exceed the vitrification initiation temperature T1 of the polylactic acid pipe, and keep it warm for 5 minutes; then rotate the blade 3. Drive the distal blade along the rotating shaft to rotate along the swing center of the distal blade and turn away from the end connected to the control rod. The speed is controlled between 1-20rpm, and the remote control rod 5 is used to control The end blade 4 is opened at a speed of 0.1° / min, gradually approaching the metal mold 1; when the distal blade 4 is opened more than 2°, the opening of the distal blade 4 is suspended, and the temperature is raised to the end temperature T2 of vitrification of the polylactic acid tube. After reaching the temperature, the rotating speed is controlled at 20-60rpm, and the distal blade 4 ...

Embodiment 2

[0037] like figure 1 , figure 2 and image 3 As shown, put the polylactic acid pipe 2 to be strengthened into the metal mold 1, the wall thickness of the polylactic acid pipe 2 is 150-200um, heat the metal mold 1 to exceed the vitrification initiation temperature T1 of the polylactic acid pipe, and keep it warm for 20 minutes; then rotate the blade 3. Drive the distal blade along the rotating shaft to rotate along the swing center of the distal blade and turn away from the end connected to the control rod. The speed is controlled between 1-20rpm, and the remote control rod 5 is used to control The end blade 4 is opened at a speed of 0.1° / min, gradually approaching the metal mold 1; when the distal blade 4 is opened more than 2°, the opening of the distal blade 4 is suspended, and the temperature is raised to the end temperature T2 of vitrification of the polylactic acid tube. After reaching the temperature, the rotating speed is controlled at 20-60rpm, and the distal blade ...

Embodiment 3

[0039] like figure 1 , figure 2 and image 3As shown, put the polylactic acid pipe 2 to be strengthened into the metal mold 1, the wall thickness of the polylactic acid pipe 2 is 300-500um, heat the metal mold 1 to exceed the vitrification initiation temperature T1 of the polylactic acid pipe, and keep it warm for 30 minutes; then rotate the blade 3. Drive the distal blade along the rotating shaft to rotate along the swing center of the distal blade and turn away from the end connected to the control rod. The speed is controlled between 1-20rpm, and the remote control rod 5 is used to control The end blade 4 is opened at a speed of 0.1° / min, gradually approaching the metal mold 1; when the distal blade 4 is opened more than 2°, the opening of the distal blade 4 is suspended, and the temperature is raised to the end temperature T2 of vitrification of the polylactic acid tube. After reaching the temperature, the rotating speed is controlled at 20-60rpm, and the distal blade 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com