Cold isostatic pressing sintering preparation method of bioglass

A technology of cold isostatic pressing and biological glass, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc., can solve the problems of material biological activity and toxicological influence, achieve broad biomedical application prospects and high production efficiency , save the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

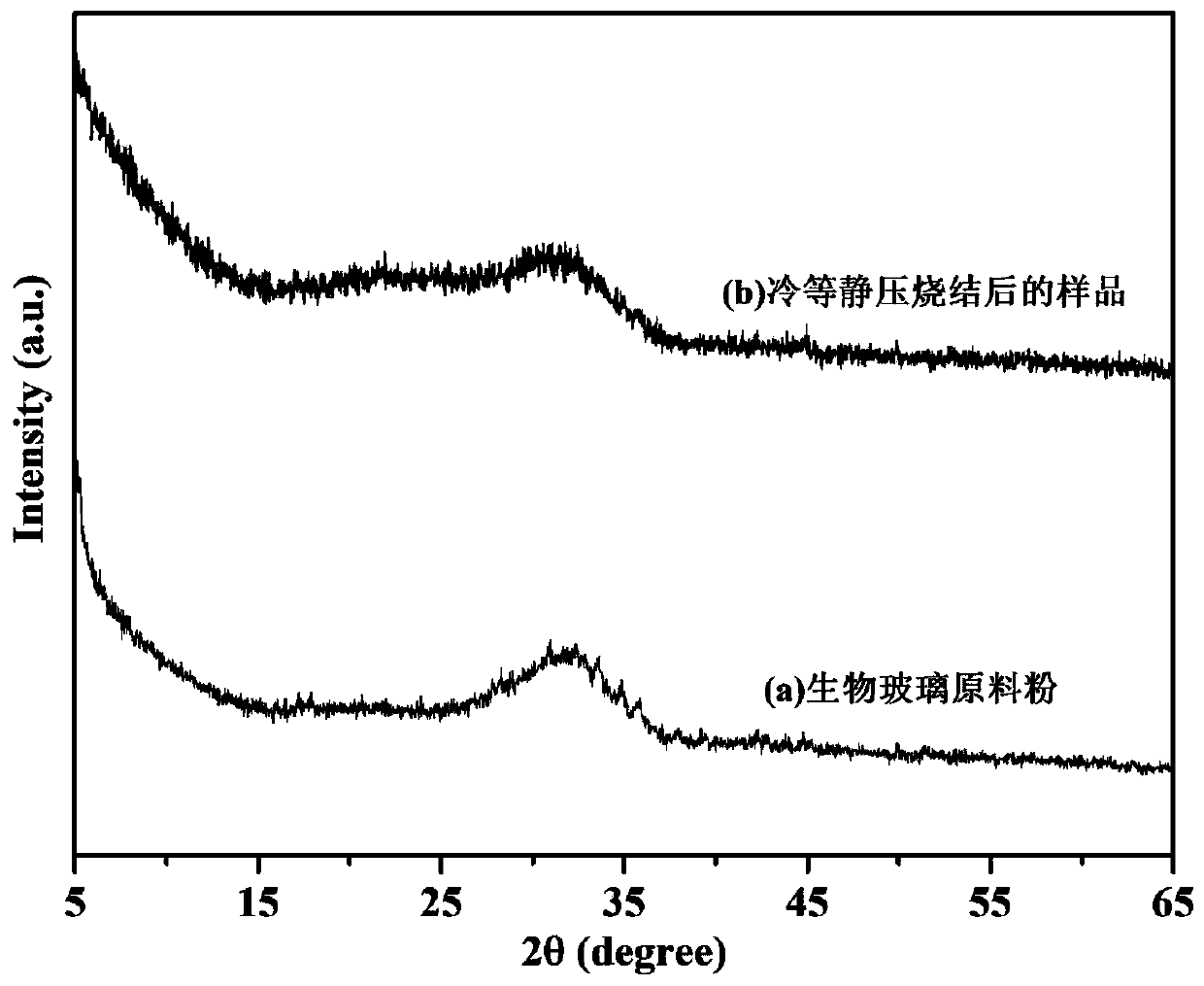

[0024] A cold isostatic pressing sintering preparation method of bioglass, comprising the following steps:

[0025] Step 1: Put 20μm biological glass powder and deionized water in a centrifuge tube, the volume fraction ratio of biological glass powder and deionized water is 3:2 (60%:40%). Then install the centrifuge tube on a vortex mixer for uniform mixing, and the mixing time is 30min.

[0026] Step 2: Fill the uniform mixed slurry of biological glass powder and deionized water into a flexible rubber mold and seal it with a rubber stopper. The three-dimensional shape of the rubber mold is cylindrical. Then, the sealed rubber mold with the mixed slurry was placed in a cold isostatic press for cold sintering. The cold isostatic pressing pressure was 300 MPa and the holding time was 120 min.

[0027] Step 3: The cold isostatic pressed rubber mold with mixed slurry was placed in a constant temperature and humidity box for drying treatment. The temperature was set at 60 °C, the ...

Embodiment 2

[0029] A cold isostatic pressing sintering preparation method of bioglass, comprising the following steps:

[0030] Step 1: Put 500 nm biological glass powder and deionized water in a centrifuge tube, the volume ratio of biological glass powder and deionized water is 3:2 (. Then install the centrifuge tube on a vortex mixer for uniform mixing , and the mixing time was 30 min.

[0031] Step 2: Fill the uniform mixed slurry of biological glass powder and deionized water into a flexible rubber mold and seal it with a rubber stopper. The three-dimensional shape of the rubber mold is a triangular prism. Then, the sealed rubber mold with the mixed slurry was placed in a cold isostatic press for cold sintering. The cold isostatic pressing pressure was 300 MPa and the holding time was 120 min.

[0032] Step 3: Put the cold isostatic pressed rubber mold containing the mixed slurry in a constant temperature and humidity box for drying treatment. The temperature is set at 50 °C, the hum...

Embodiment 3

[0034] A cold isostatic pressing sintering preparation method of bioglass, comprising the following steps:

[0035] Step 1: Put 500 nm biological glass powder and deionized water in a centrifuge tube, the volume fraction ratio of biological glass powder and deionized water is 4:1. Then the centrifuge tube was installed on a vortex mixer for uniform mixing, and the mixing time was 30 min.

[0036] Step 2: Fill the uniform mixed slurry of biological glass powder and deionized water into a flexible rubber mold and seal it with a rubber stopper. The three-dimensional shape of the rubber mold is a square prism. Then, the sealed rubber mold with the mixed slurry was placed in a cold isostatic press for cold sintering. The cold isostatic pressing pressure was 300 MPa and the holding time was 120 min.

[0037] Step 3: The cold isostatic pressed rubber mold with mixed slurry was placed in a constant temperature and humidity box for drying treatment. The temperature was set at 60 °C, t...

PUM

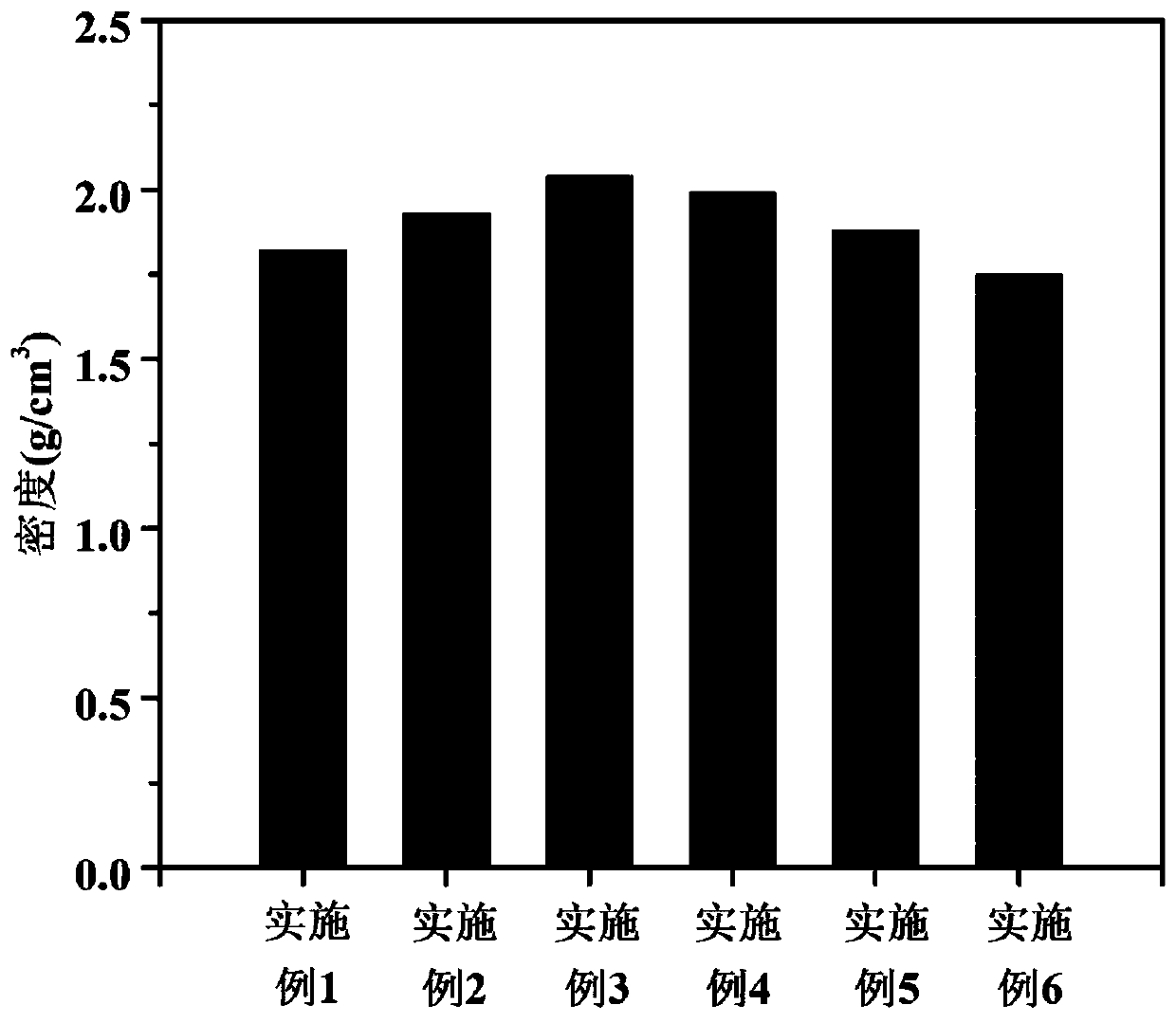

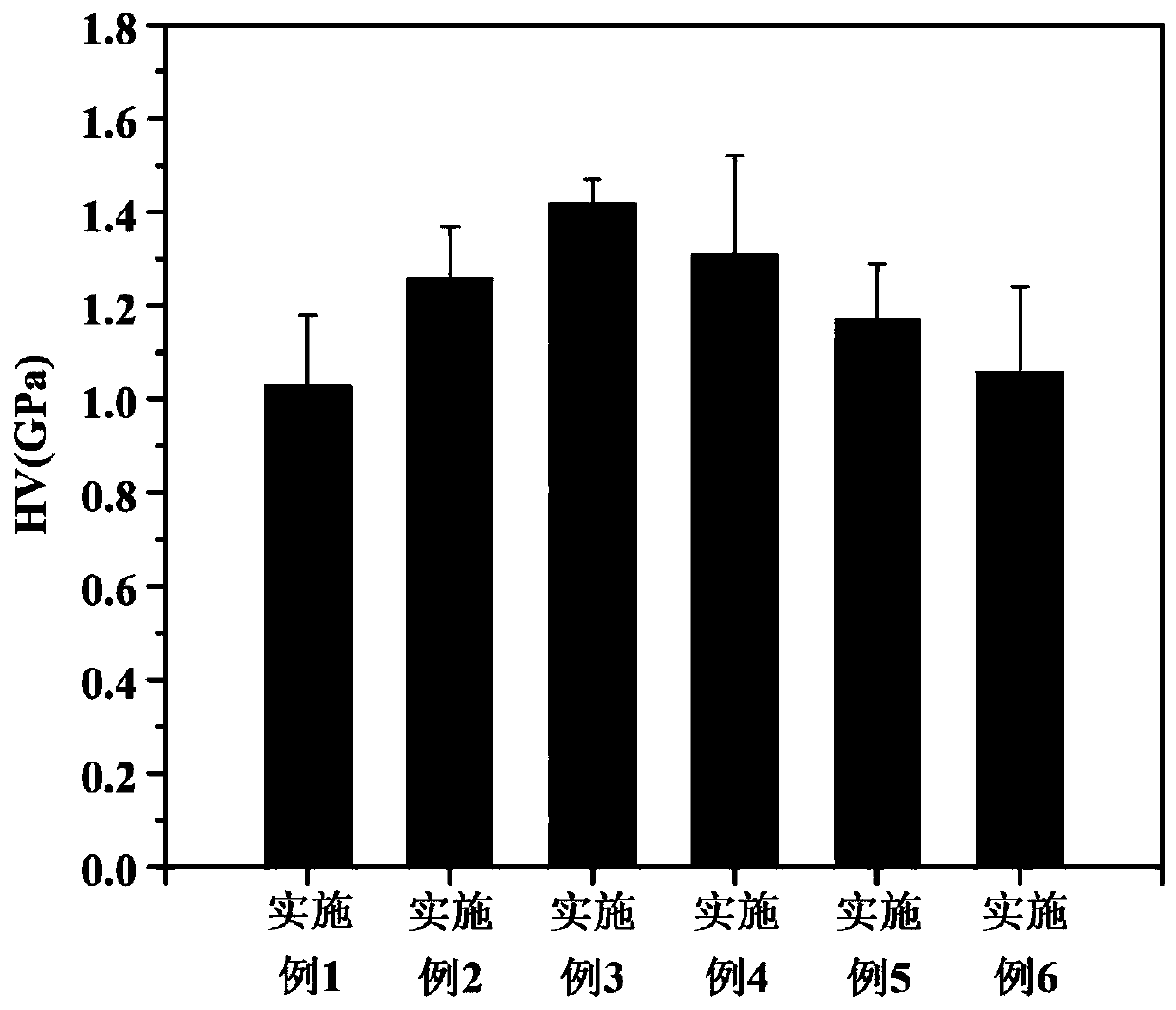

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com