Full-body color-changing light-transmitting ceramic tile and preparation method thereof

A kind of ceramic tile and whole body technology, which is applied in the direction of ceramic molding machines, manufacturing tools, clay products, etc., can solve the problems of easy blistering of the glaze surface, affect the quality of the glaze surface, and poor color development effect, so as to achieve the effect of improving the artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the whole body color-changing light-transmitting ceramic tile comprises the following steps:

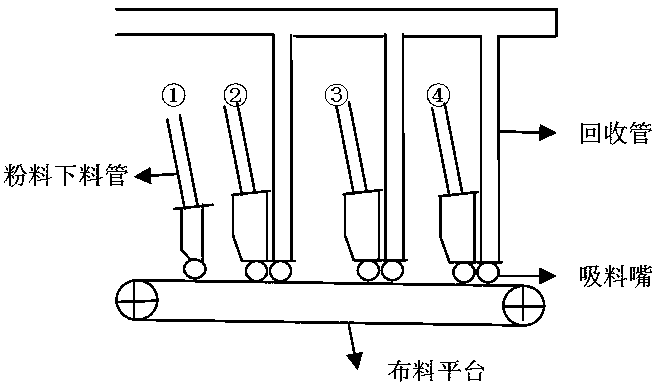

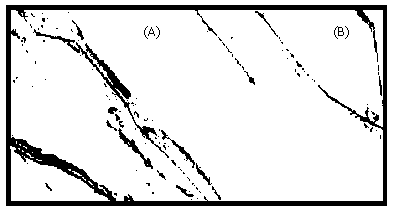

[0049] Step 1: Spread the light-transmitting powder through the lower hopper, and then spread the light-transmitting and color-changing powder by suction and backfilling. According to the selected design layout, use CAD software to draw the line part of the pattern into a graphic file at a ratio of 1:1 according to the pattern texture, the control system recognizes the graphic file and generates a signal, and transmits the signal to the corresponding suction system and filling material system Carry out corresponding suction and feeding actions. When the fabric system receives the signal, the light-transmitting powder feeding tube (such as figure 2 middle ) Distribute light-transmitting powder evenly on the fabric platform as the base material, and the belt conveys it to the first group of toner suction and filling stations. The suction system reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com