Pressurized kirschner wire

A Kirschner wire and needle body technology, which is applied in the field of pressurized Kirschner wires, can solve the problems of inability to obtain mechanical stability, delayed fracture healing time, and infection of granulation at the entrance of the needle, so as to reduce granulation hyperplasia and reduce skin and soft tissue infections. , the effect of reducing the fracture line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

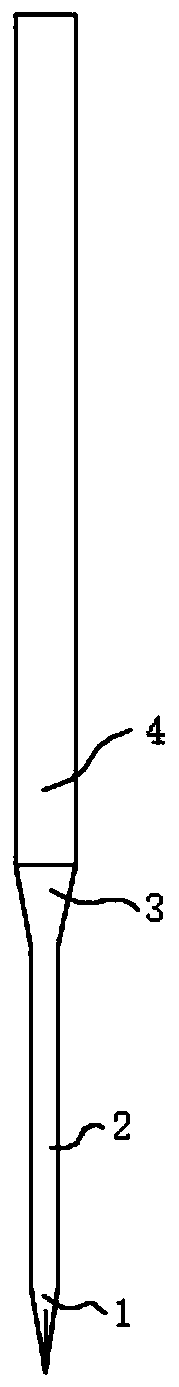

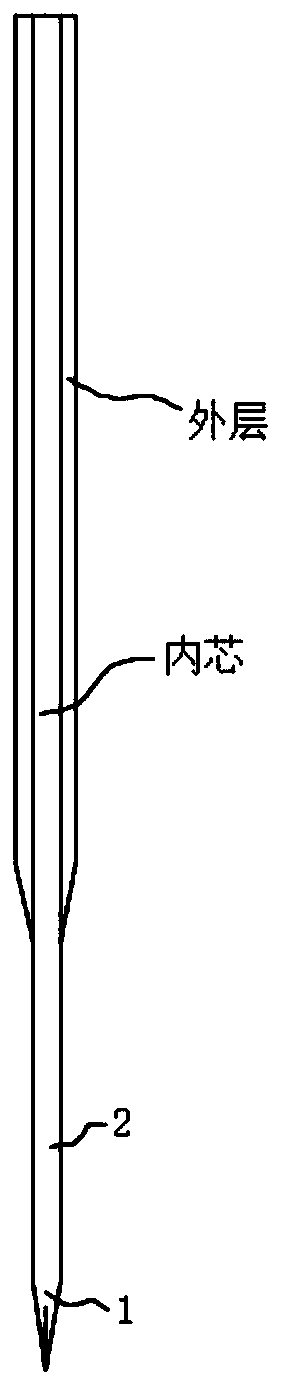

[0027] see Figure 1-2 , the present invention provides a technical solution: a pressurized Kirschner wire, comprising a Kirschner wire body, the Kirschner wire body has a needle tip portion 1, a needle body detail portion 2, a needle body transition portion 3 and a needle body rear portion 4, the needle body Both the body transition part 3 and the needle body rear part 4 have an outer layer and an inner core, and the outer layer covers the inner core.

[0028] In this embodiment, when the Kirschner wire body is made of uniform material, the outer layer and the inner core of the needle body moving part 3 and the needle body rear part 4 are made of uniform material, and any point has the same physical and chemical properties.

[0029] In this embodiment, when the Kirschner wire body is made of non-uniform material, the outer layer of the needle body transition part 3 and the needle body rear part 4 is made of non-absorbable material, and the inner core is made of absorbable mat...

Embodiment 2

[0031] see Figure 1-2 , the present invention provides a technical solution: a pressurized Kirschner wire, comprising a Kirschner wire body, the Kirschner wire body has a needle tip portion 1, a needle body detail portion 2, a needle body transition portion 3 and a needle body rear portion 4 , the needle tip 1 is a tapered tip, the rear end of the needle tip 1 is connected to the needle body detail 2; The needle body transition part 3 is connected, and the end of the needle body transition part 3 extends to the end of the needle body rear part 4, and the needle body transition part 1 and the needle body rear part 4 are connected to form a smooth cone structure; the needle body travels Both the part 3 and the rear part 4 of the needle body have an outer layer and an inner core, and the outer layer covers the inner core.

[0032] In this embodiment, the Kirschner wire body is a uniform material, which is a metal material or a human body absorbable material, and the specific ma...

Embodiment 3

[0036] When the Kirschner needle body is made of human body absorbable material and human body non-absorbable material, the needle tip part 1 and needle body detail part 2 are made of absorbable material, the needle body rear part 4 is made of non-absorbable material, and the needle body transition part 3 can It is a material that can be absorbed by the human body or a material that cannot be absorbed by the human body. According to clinical needs, the needle body part of the non-absorbable material is removed after a certain treatment time.

[0037] In this embodiment, when the Kirschner needle body is made of human body absorbable material and human body non-absorbable material inside and outside, the needle tip part 1, the needle body detail part 2, the inner core of the needle body moving part 3, and the inner core of the needle body rear part 4 The core is made of absorbable material, and the outer layers of the needle body transition part 3 and the needle body rear part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com