Polyphenol-mediated prussian blue/quartz nano composite film and preparation method and application thereof

A Prussian blue and nanocomposite technology, applied in the field of Prussian blue/quartz nanocomposite film and its preparation, achieves the effect of simple operation process, good stability and good organic dye degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A quartz membrane with a thickness of 0.4 mm was immersed in FeCl with a concentration of 1 mg / mL 3 and 4 mg / mL TA with a volume ratio of 1:1, rinsed in water for 5 min, and dried in an oven at 45°C for 2 min; then immersed the omentum in 1 mg / mL FeCl 3 solution, reacted for 2 min and dried at 45°C, and finally immersed the omentum in 1 mg / mL potassium ferrocyanide solution, rinsed in clean water after reacting for 5 min, and dried in an oven at 45°C to obtain PB / TA-Fe@QF composite membrane.

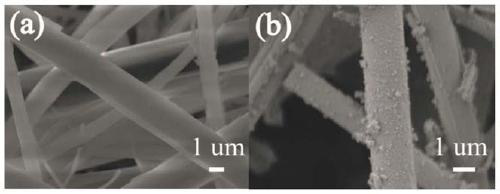

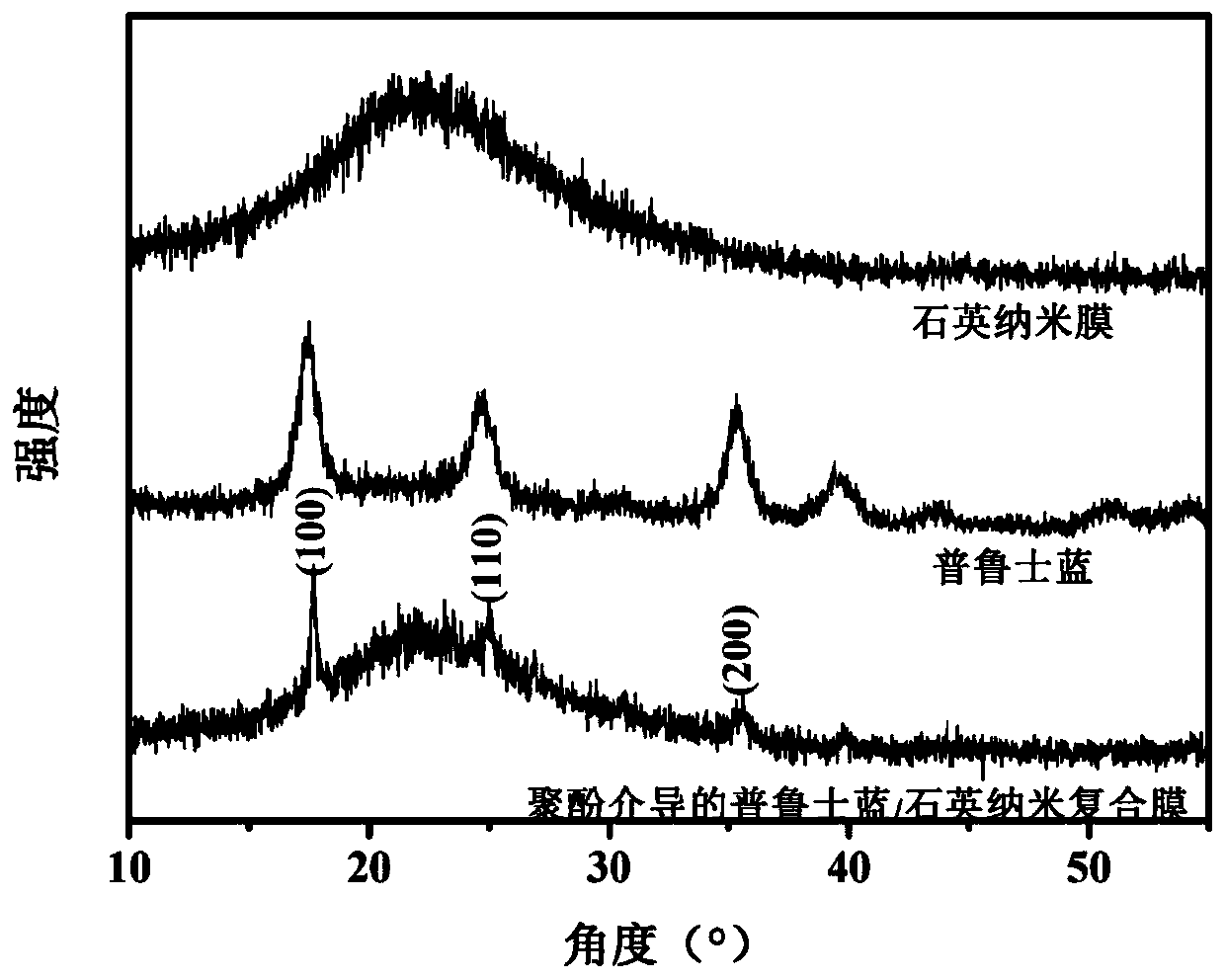

[0031] The surface morphology characteristics of the prepared PB / TA-Fe@QF composite film and the quartz film before modification were observed by scanning electron microscope (SEM). figure 1 It is the SEM image of the prepared PB / TA-Fe@QF composite film and the quartz film before modification; in the figure, (a) is the quartz film before modification, and (b) is the prepared PB / TA-Fe@QF composite film ;Depend on figure 1 It can be seen that the prepared PB / TA-Fe@QF composite m...

Embodiment 2

[0034] A quartz membrane with a thickness of 0.5 mm was immersed in FeCl with a concentration of 0.5 mg / mL 3 and 2.5 mg / mL TA with a volume ratio of 1:1, rinsed in clean water after 2 min, and dried in an oven at 45 °C for 2 min; then immersed the omentum in 0.5 mg / mL FeCl 3 After reacting for 2 minutes, place it in an oven at 55°C to dry, and finally immerse the omentum in 0.5 mg / mL potassium ferrocyanide solution, react for 5 minutes, then rinse it in clean water, and put it in an oven at 45°C Dry in medium to obtain PB / TA-Fe@QF composite membrane.

Embodiment 3

[0036] A quartz membrane with a thickness of 0.6 mm was immersed in FeCl with a concentration of 1 mg / mL 3 and 3 mg / mL TA with a volume ratio of 1:1, rinsed in clean water after 2 min, and dried in an oven at 45 °C for 2 min; then immersed the omentum in 10 mg / mL FeCl 3 After reacting for 2 minutes, place the omentum in a 45°C oven to dry, and finally immerse the omentum in 10 mg / mL potassium ferrocyanide solution, react for 5 minutes, then rinse it in clean water, and put it in a 45°C oven Dry in medium to obtain PB / TA-Fe@QF composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com