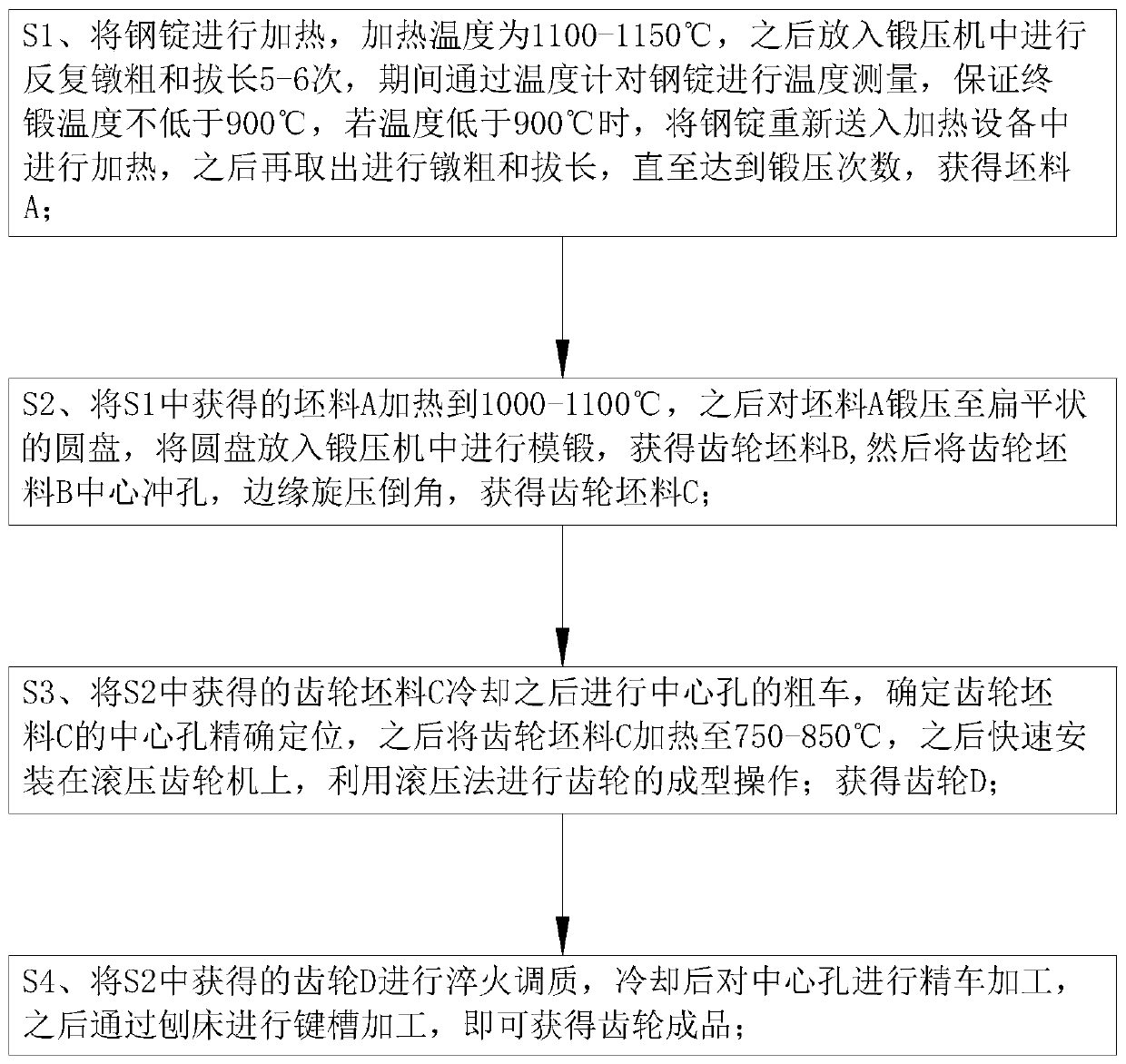

Forging technology of single-oil-groove bevel gear

A technology of helical gears and oil grooves is applied in the field of forging technology of helical gears with single oil grooves, which can solve the problems affecting the machining accuracy of gears and the overall deformation of the gears, and achieve the effects of improving machining efficiency, ensuring smoothness and increasing machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

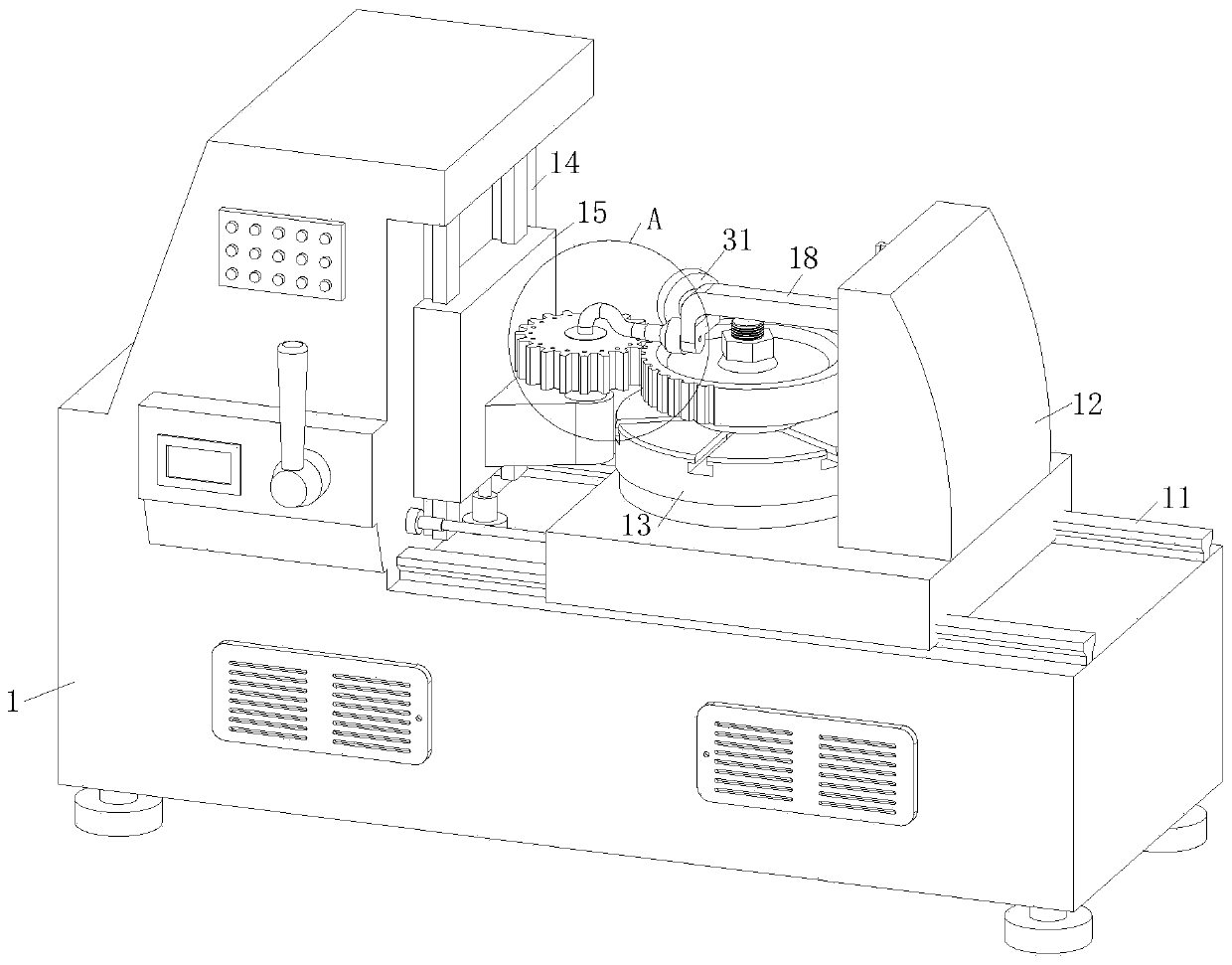

Image

Examples

Embodiment approach

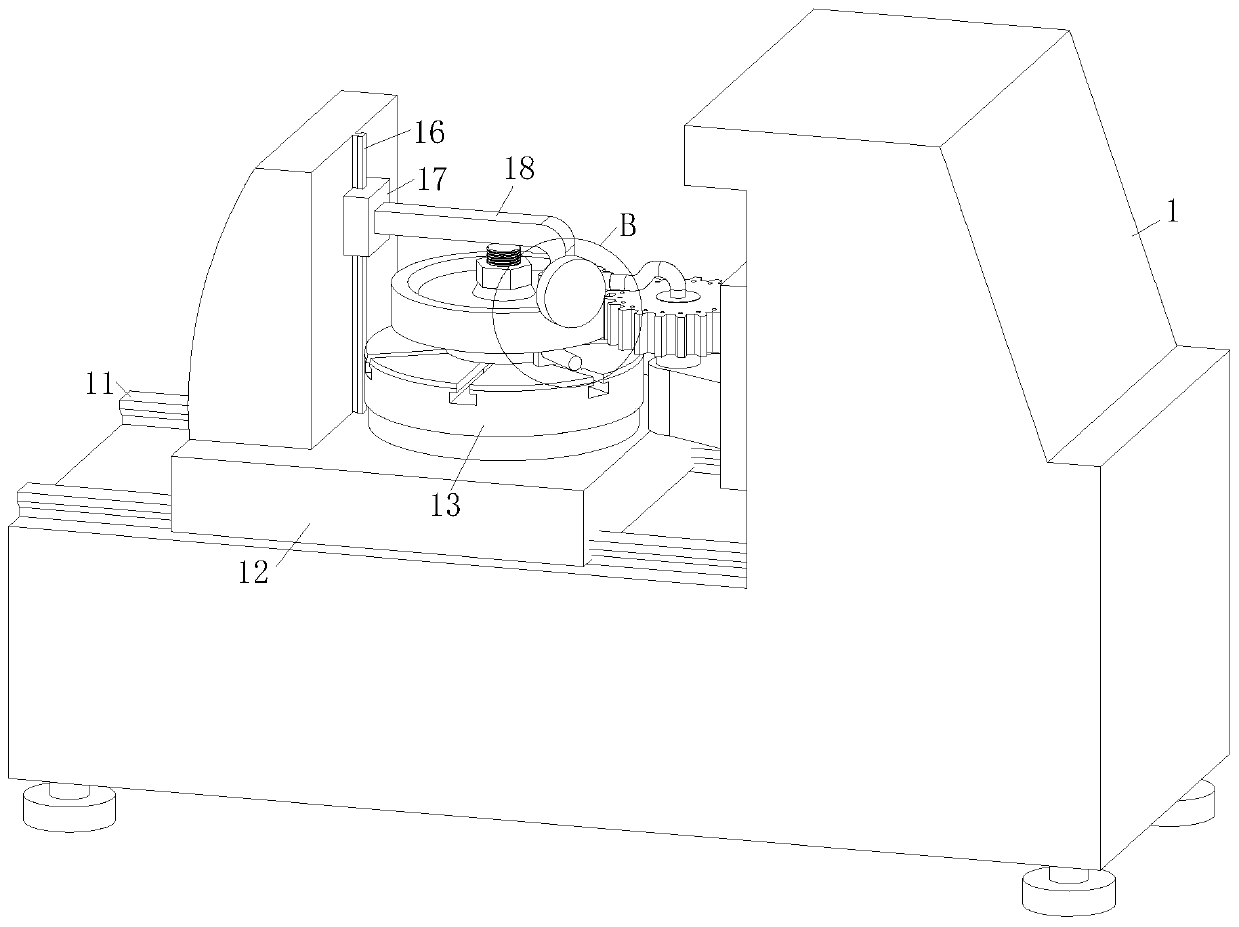

[0036] As an embodiment of the present invention, the end of the tapered portion 22 away from the bracket 18 is provided with a cylindrical shaping portion 23, the shaping portion 23 is used to reduce the lug formed in the axial direction when the gear blank is rolled; when the gear When the outer edge of the blank is squeezed by the rolling wheel 2, the rolling wheel 2 squeezes the gear blank so that the outer edge of the high-temperature gear blank deforms and flows to form a tooth shape. At this time, a part of the gear blank is deformed to the axial direction of the center hole of the gear blank to form The lug increases the follow-up cutting work of the gear. The end of the tapered part 22 away from the bracket 18 is provided with a cylindrical shaping part 23, which squeezes and shapes both sides of the gear, thereby ensuring the smoothness of both sides of the gear and avoiding the occurrence of lugs. , thereby improving the gear machining efficiency.

[0037] As an emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com