A kind of preparation method of high heat resistance, high reliability cem-1 copper clad laminate

A CEM-1, reliable technology, used in chemical instruments and methods, printed circuit manufacturing, paper/cardboard layered products, etc., can solve the problems of non-punching, poor machinability, high manufacturing cost, and reduce the explosion of boards. rate, good adhesion performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

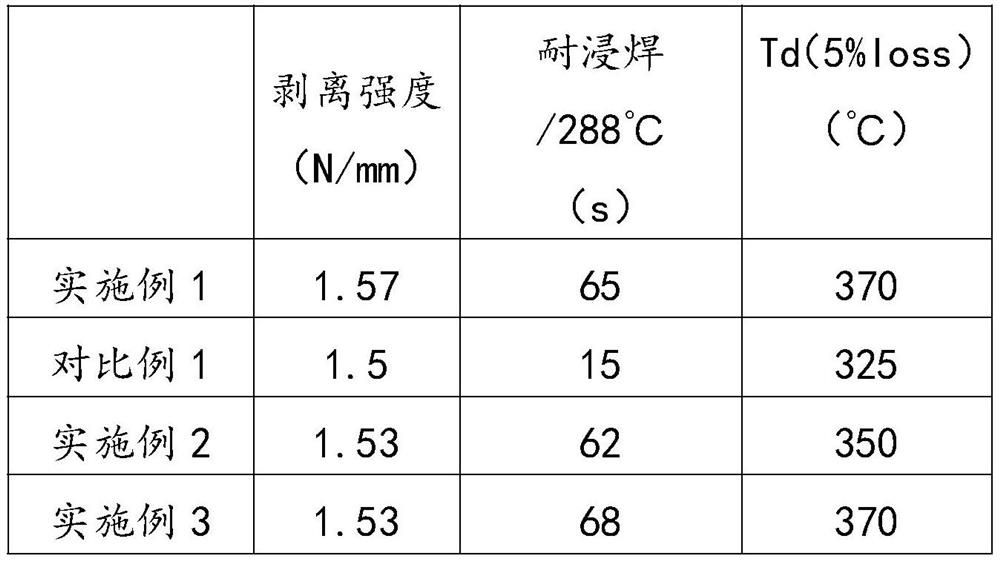

Examples

Embodiment 1

[0026] A method for preparing a CEM-1 copper clad laminate with high heat resistance and high reliability, the steps are as follows:

[0027] (1) Preparation of surface material resin: by weight, 59 parts of solvent-based epoxy resin (the epoxy equivalent of low-bromine epoxy resin is 410g / eq, bromine content is 20wt%), 1 part of curing agent Dicyandiamide, 0.1 part of silane coupling agent KH-550, 0.1 part of curing accelerator 2-methylimidazole, 19 parts of solvent DMF and 21 parts of flame retardant aluminum hydroxide are mixed and stirred evenly;

[0028] (2) Prepare lining-impregnation resin: by weight, 40 parts of water-soluble phenolic resin, 200 parts of methanol, 30 parts of acetone and 100 parts of water are mixed and stirred evenly;

[0029] (3) Preparation of lining secondary dipping resin: by weight, 43 parts of polyvinyl formal-polyvinyl alcohol-polyacrylic acid copolymer, 40 parts of E-51 epoxy resin, 125 parts of solvent-type phenolic resin, 20 parts of cyanat...

Embodiment 2

[0042] A method for preparing a CEM-1 copper clad laminate with high heat resistance and high reliability, the steps are as follows:

[0043] (1) Preparation of table material resin: 40 parts of solvent-based epoxy resin (the epoxy equivalent of low-bromine epoxy resin is 420g / eq, bromine content is 20wt%), 1 part of curing agent dicyandiamide, 0.1 part Curing accelerator 2-methylimidazole, 25 parts of solvent acetone and 25 parts of flame retardant aluminum hydroxide are mixed and stirred evenly;

[0044] (2) Preparation of lining-impregnation resin: by weight parts, 30 parts of water-soluble phenolic resin, 180 parts of methanol, 40 parts of acetone and 120 parts of water are mixed and stirred evenly;

[0045](3) Preparation of lining two-impregnation resin: in parts by weight, 40 parts of polyvinyl formal-polyvinyl alcohol-polyacrylic acid copolymer, 20 parts of tetrabromobisphenol A type epoxy resin (epoxy equivalent is 410g / eq), 128 parts of solvent-based phenolic resin,...

Embodiment 3

[0050] A method for preparing a CEM-1 copper clad laminate with high heat resistance and high reliability, the steps are as follows:

[0051] (1) Preparation of table material resin: 55 parts of solvent-based epoxy resin (the epoxy equivalent of low-bromine epoxy resin is 410g / eq, bromine content is 20wt%), 1 part of curing agent dicyandiamide, 0.1 part Curing accelerator 2-methylimidazole, 35 parts of solvent butanone, 5 parts of flame retardant aluminum hydroxide, 10 parts of flame retardant magnesium hydroxide and 5 parts of flame retardant antimony trioxide are mixed and stirred evenly;

[0052] (2) Prepare lining-impregnation resin: by weight, 35 parts of water-soluble phenolic resin, 200 parts of methanol, 35 parts of acetone and 120 parts of water are mixed and stirred evenly;

[0053] (3) Preparation of lining secondary dipping resin: by weight, 45 parts of polyvinyl formal-polyvinyl alcohol-polyacrylic acid copolymer, 30 parts of phosphorus-containing epoxy resin (epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com