A waste heat filtration equipment for dual-standard classification of sewage

A filter equipment and dual-standard technology, which is applied in the field of sewage dual-standard graded waste heat filtration equipment, can solve the problems of low waste heat utilization rate, waste of sewage heat, and low sewage recovery rate, so as to increase recycling rate, increase applicability, Increases the effect of recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

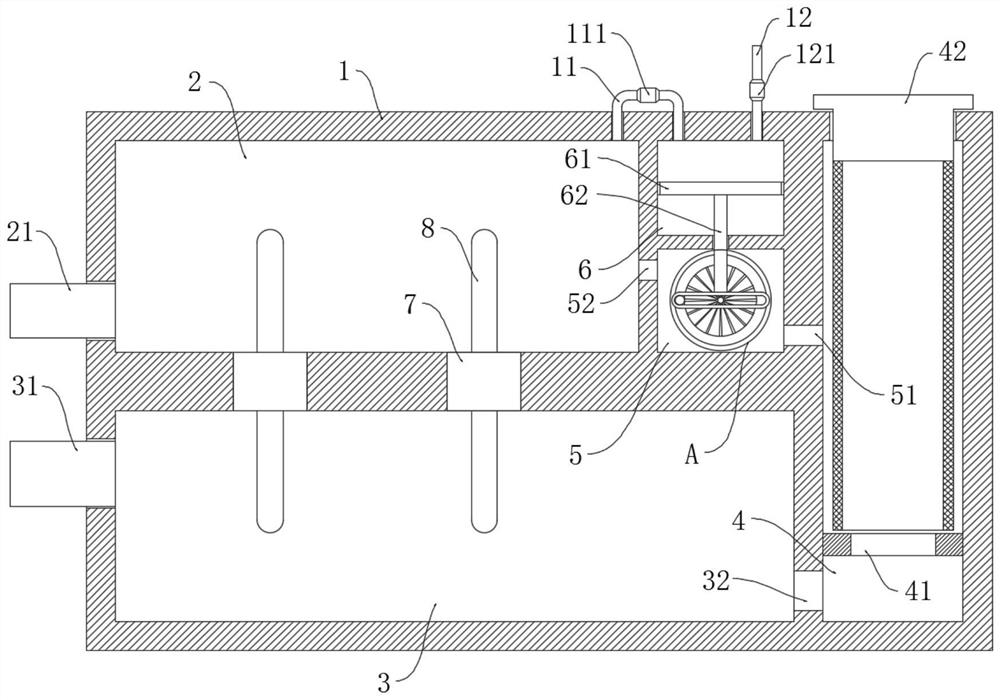

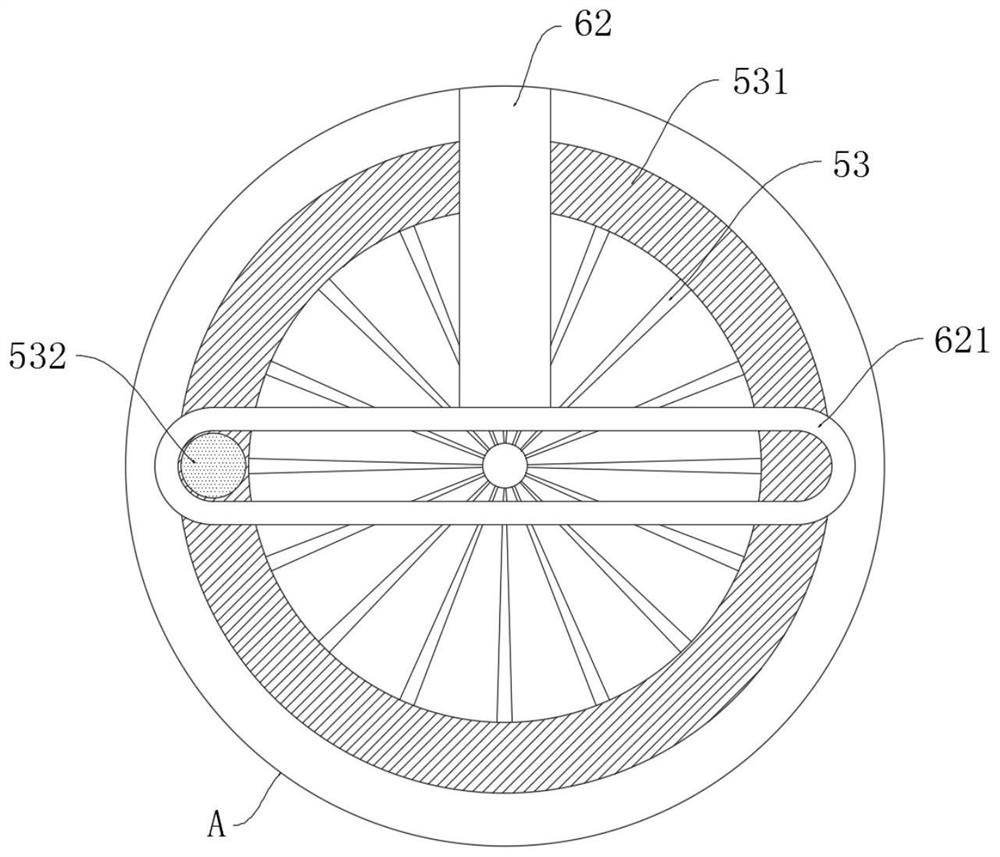

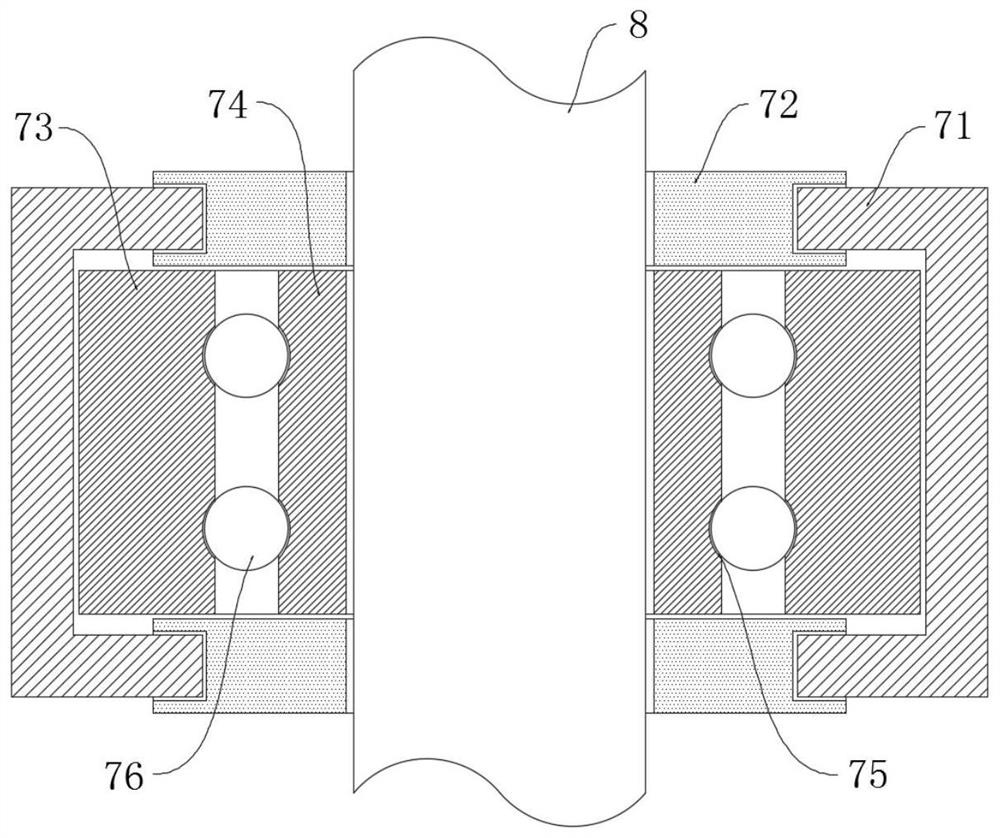

[0022] refer to Figure 1-3 , a waste heat filtration device with dual specifications for classification and utilization of waste heat, including a body 1, which is divided into a water purification chamber 2, a sewage chamber 3, a filter chamber 4, a power chamber 5, and a pressure chamber 6, the water purification chamber 2 and the sewage chamber 3 A plurality of floating bushings 7 are embedded between them, and a superconducting heat pipe 8 is inserted on each floating bushing 7. The floating bushing 7 includes a casing 71, and sealing rubber rings 72 are embedded at both ends of the casing 71. The inner wall of 71 is equipped with an outer ring cover 73, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com