Indirect oil gas condensation recovery device and recovery process thereof

A technology of condensation recovery, oil and gas, applied in the petroleum industry, vapor condensation, liquid hydrocarbon mixture recovery and other directions, can solve the problems of affecting the working performance of the refrigeration system, not considering the recovery of cooling capacity, unstable operation of the refrigeration system, etc., to avoid suction. The effect of the temperature is too low, the electric energy is reduced, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

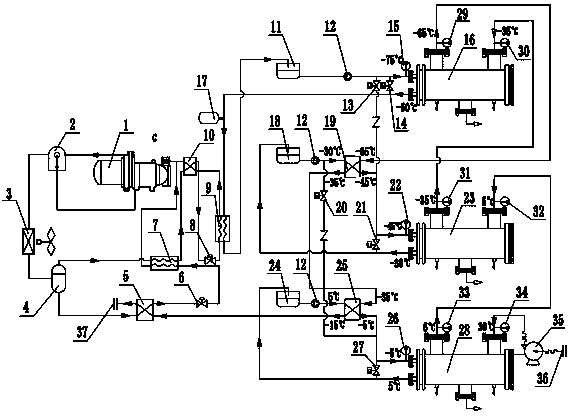

[0030] The specific embodiment of the present invention is described in further detail below in conjunction with embodiment accompanying drawing:

[0031] The accompanying drawings are for illustrative purposes only, and should not be construed as limiting the present invention. In order to better illustrate the following embodiments, some components in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art, some known structures and their descriptions in the drawings may be omitted. understandable.

[0032] Such as figure 1 The illustrated embodiment is an indirect oil and gas condensation recovery device and its recovery process. The recovery device includes: an oil and gas delivery system, a cooling system and a low-temperature refrigeration system; the oil and gas delivery system includes a deep cooler 16 and a shallow cooler 23 And precooler 28; Described load cooling system comprises the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com