A kind of martensitic precipitation hardening stainless steel and its preparation method and application

A precipitation hardening, stainless steel technology, applied in the field of alloy steel manufacturing, can solve the problems of low strength, unable to meet the needs of stainless steel strength use, etc., to achieve the effect of improving purity, reducing inclusions in steel, and optimizing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

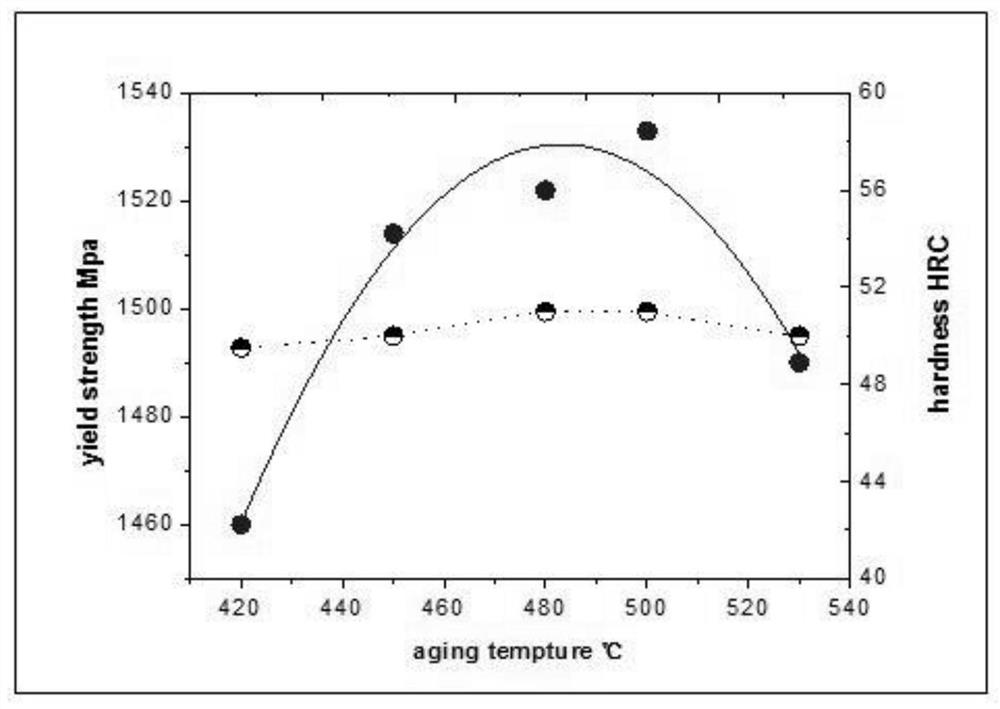

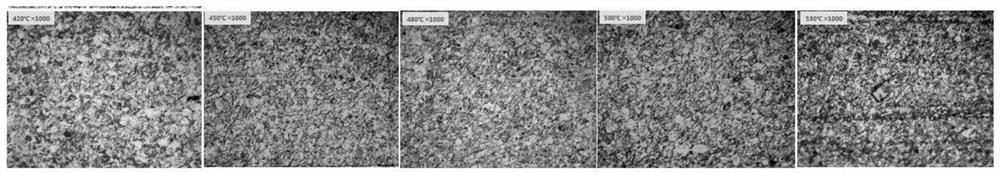

[0045] This embodiment provides a martensitic precipitation hardening stainless steel, the chemical composition of the martensitic precipitation hardening stainless steel includes: C: 0.045%; Si: 1.62%; Mn: 0.72%; P: 0.025%; S : 0.0015%; Cr: 14.3%; Ni: 7.1%; Al: 0.04~0.06%; Mo: 0.65%; Cu: 0.82%; N: 0.01%; Ti: 0.32%; the balance is iron and other unavoidable Impurities. The martensitic precipitation hardening stainless steel is obtained by smelting, continuous casting, hot rolling, hot annealing pickling, cold rolling, cold rolling annealing pickling, smoothing and aging of the raw materials of martensitic precipitation hardening stainless steel; specifically:

[0046] A. Smelting and continuous casting: Through EAF+AOD+VOD+CCP, VOD adopts vacuum decarburization technology, vacuum stirring for 73 minutes, the inclusions in the steel are fully floating, effectively reducing the inclusions in the steel, using Al deoxidation to further reduce the Total in the steel[ O], thereby r...

Embodiment 2

[0054] This embodiment provides a martensitic precipitation hardening stainless steel, the chemical composition of the martensitic precipitation hardening stainless steel includes: C: 0.043%; Si: 1.74%; Mn: 0.77%; P: 0.0235%; S : 0.0020%; Cr: 14.5%; Ni: 7.17%; Al: 0.111%; Mo: 0.75%; Cu: 0.86%; N: 0.01%; Ti: 0.225%; the balance is iron and other inevitable impurities. The martensitic precipitation hardening stainless steel is obtained by smelting, continuous casting, hot rolling, hot annealing pickling, cold rolling, cold rolling annealing pickling, smoothing and aging of the raw materials of martensitic precipitation hardening stainless steel; specifically:

[0055] A. Smelting and continuous casting: Through EAF+AOD+VOD+CCP, VOD adopts vacuum decarburization technology, vacuum stirring for 73 minutes, the inclusions in the steel are fully floating, effectively reducing the inclusions in the steel, using Al deoxidation to further reduce the Total in the steel[ O], thereby redu...

Embodiment 3

[0063] This embodiment provides a martensitic precipitation hardening stainless steel, the chemical composition of the martensitic precipitation hardening stainless steel includes: C: 0.0557%; Si: 1.713%; Mn: 0.7%; P: 0.025%; S : 0.0016%; Cr: 14.4%; Ni: 7.14%; Al: 0.045%; Mo: 0.62%; Cu: 0.77%; N: 0.0068%; Ti: 0.34%; the balance is iron and other inevitable impurities. The martensitic precipitation hardening stainless steel is obtained by smelting, continuous casting, hot rolling, hot annealing pickling, cold rolling, cold rolling annealing pickling, smoothing and aging of the raw materials of martensitic precipitation hardening stainless steel; specifically:

[0064] A. Smelting and continuous casting: Through EAF+AOD+VOD+CCP, VOD adopts vacuum decarburization technology, vacuum stirring for 73 minutes, the inclusions in the steel are fully floating, effectively reducing the inclusions in the steel, using Al deoxidation to further reduce the Total in the steel[ O], thereby red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com