Mudar floss microwave extraction device and application method thereof

A technology of horn melon fiber and extraction device, which is applied in the direction of separating plant fibers from seeds, etc., can solve the problems of limited microwave effect of horn melon fruit, difficult separation of cyst seed fibers, and affecting fiber quality, so as to improve extraction efficiency and purity Accurate, full and comprehensive blasting, high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

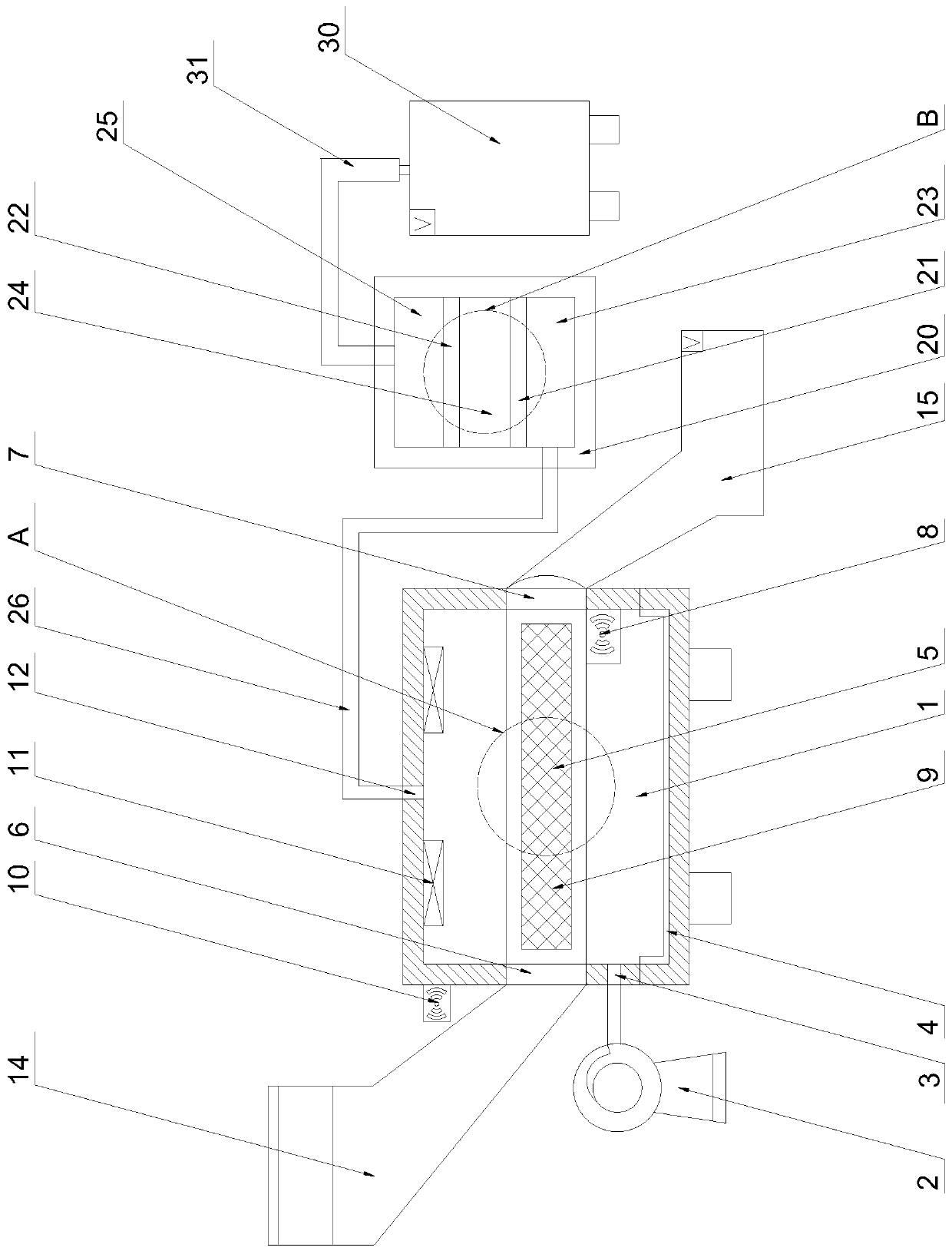

[0044] Such as Figure 1-3As shown, a kind of microwave extracting device of horn melon fiber proposed by the present invention comprises a microwave working chamber 1, a blowing device 2, a trash collection box 4, a drum assembly 5, a sound control induction device 10, a microwave generator 11, and a feeding bin 14 , waste bin 15, filter collection equipment, suction equipment and control system;

[0045] The microwave working chamber 1 is respectively provided with a feed end 6 and a discharge end 7 along the lateral sides;

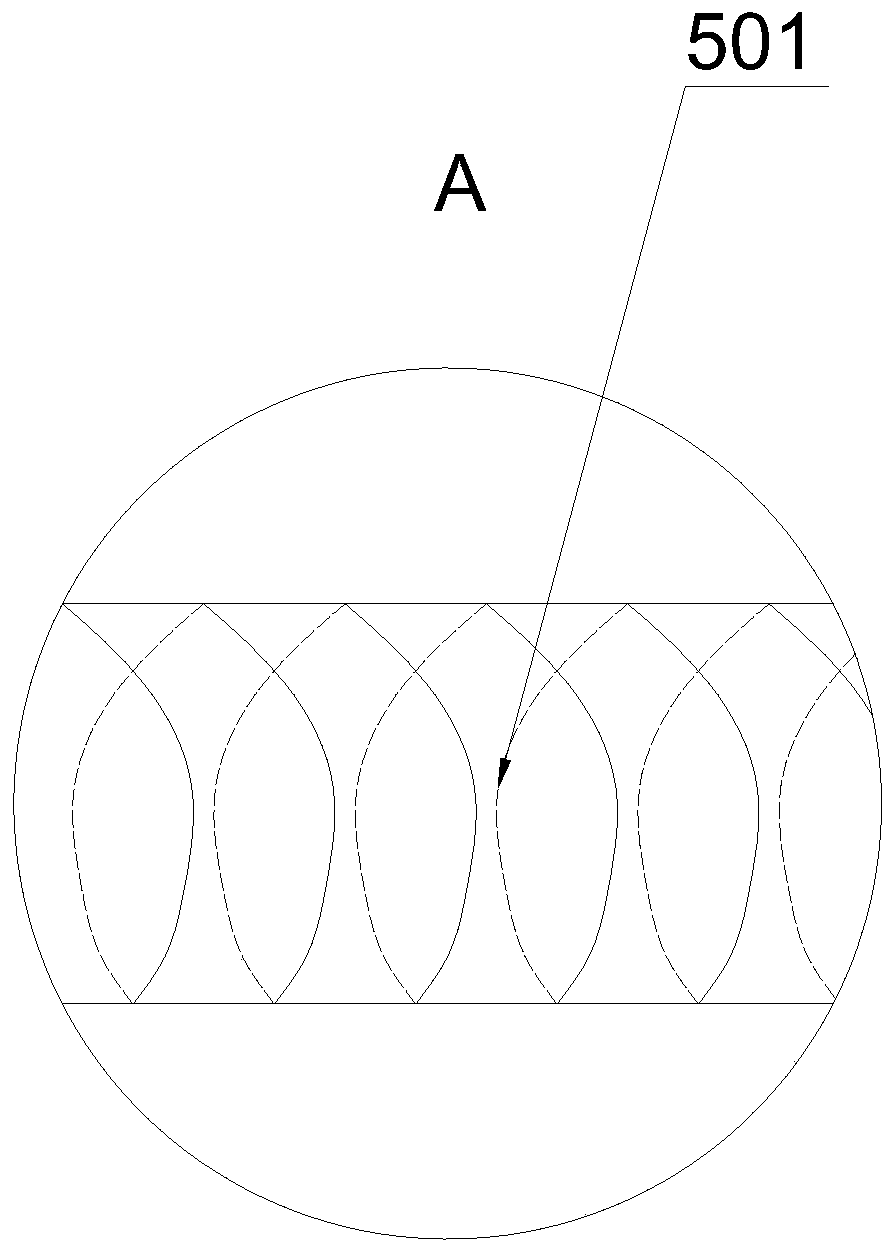

[0046] The drum assembly 5 is horizontally arranged inside the microwave working chamber 1; wherein, the discharge end of the feed bin 14 communicates with the feed end of the drum assembly 5 through the feed end 6, and the discharge end of the drum assembly 5 passes through the discharge end 7 It is connected to the feeding end of the waste bin 15; the inside of the drum assembly 5 is provided with a screw pusher 501; the outer periphery of the drum a...

Embodiment 2

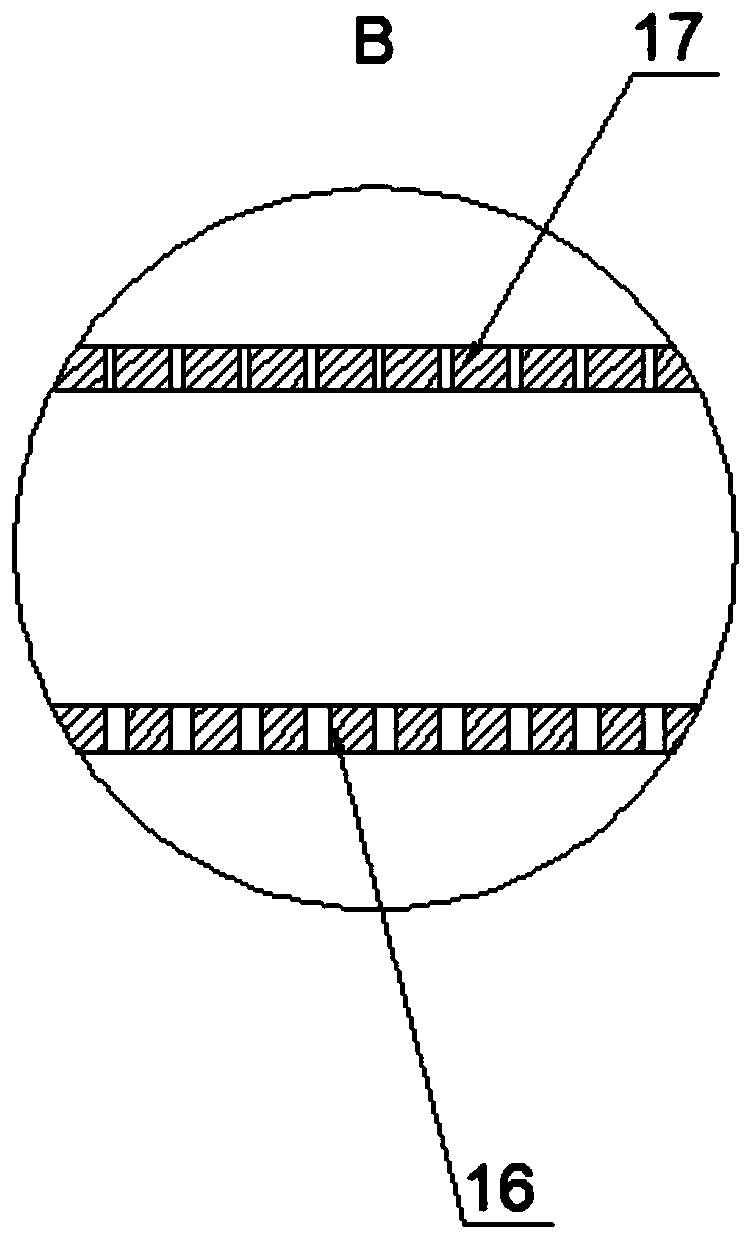

[0064] Such as Figure 4-5 As shown: a microwave extraction device for horn melon fiber proposed by the present invention, including a microwave working chamber 1, a blowing device 2, a trash collection box 4, a drum assembly 5, a sound-controlled induction device 10, a microwave generator 11, and a feeding bin 14 , waste bin 15, filter collection equipment, suction equipment and control system;

[0065] The microwave working chamber 1 is respectively provided with a feed end 6 and a discharge end 7 along the lateral sides;

[0066] The drum assembly 5 is horizontally arranged inside the microwave working chamber 1; wherein, the discharge end of the feed bin 14 communicates with the feed end of the drum assembly 5 through the feed end 6, and the discharge end of the drum assembly 5 passes through the discharge end 7 It is connected to the feeding end of the waste bin 15; the inside of the drum assembly 5 is provided with a screw pusher 501; the outer periphery of the drum ass...

Embodiment 3

[0083] Such as Figure 6-7 As shown: a microwave extraction device for horn melon fiber proposed by the present invention, including a microwave working chamber 1, a blowing device 2, a trash collection box 4, a drum assembly 5, a sound-controlled induction device 10, a microwave generator 11, and a feeding bin 14 , waste bin 15, filter collection equipment, suction equipment and control system;

[0084] The microwave working chamber 1 is respectively provided with a feed end 6 and a discharge end 7 along the lateral sides;

[0085]The drum assembly 5 is horizontally arranged inside the microwave working chamber 1; wherein, the discharge end of the feed bin 14 communicates with the feed end of the drum assembly 5 through the feed end 6, and the discharge end of the drum assembly 5 passes through the discharge end 7 It is connected to the feed end of the waste bin 15; the drum assembly 5 is provided with a screw pusher 501; the outer circumference of the drum assembly 5 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com