Multifunctional brick paving device

A brick laying device and multi-functional technology, which can be used in construction, building construction, etc., can solve problems such as affecting physical health, consuming workers' physical strength and labor time, and reducing brick laying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

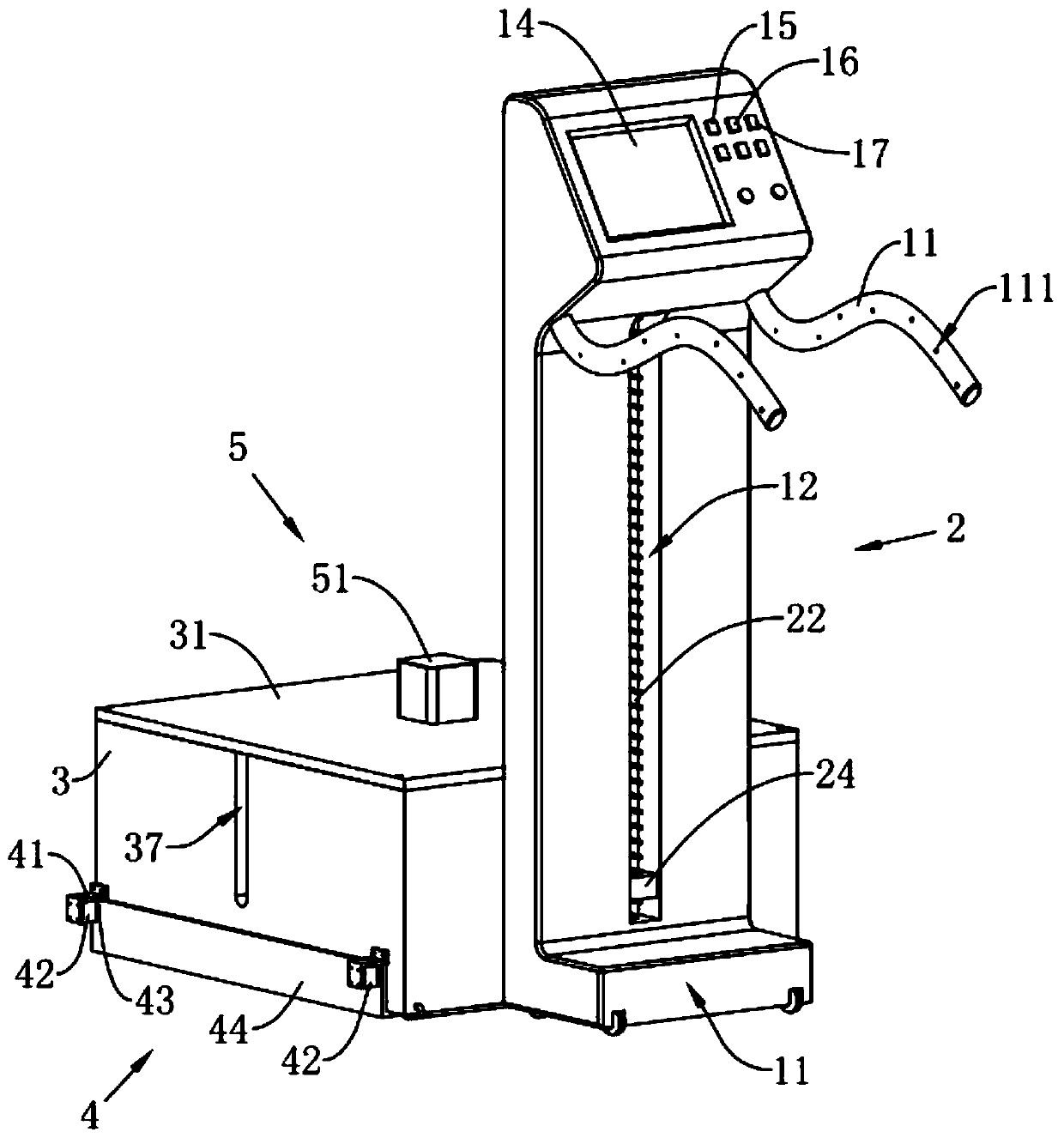

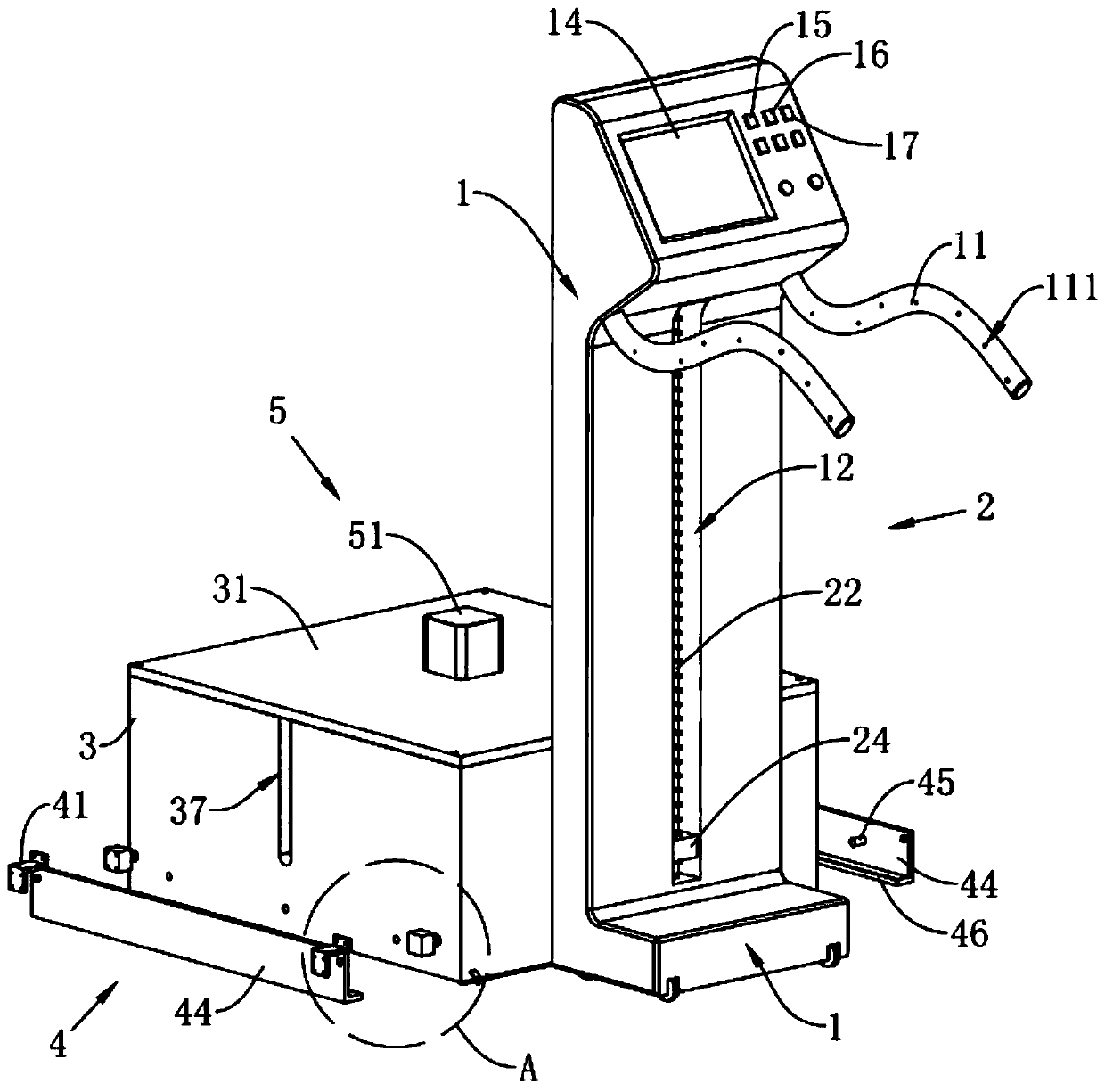

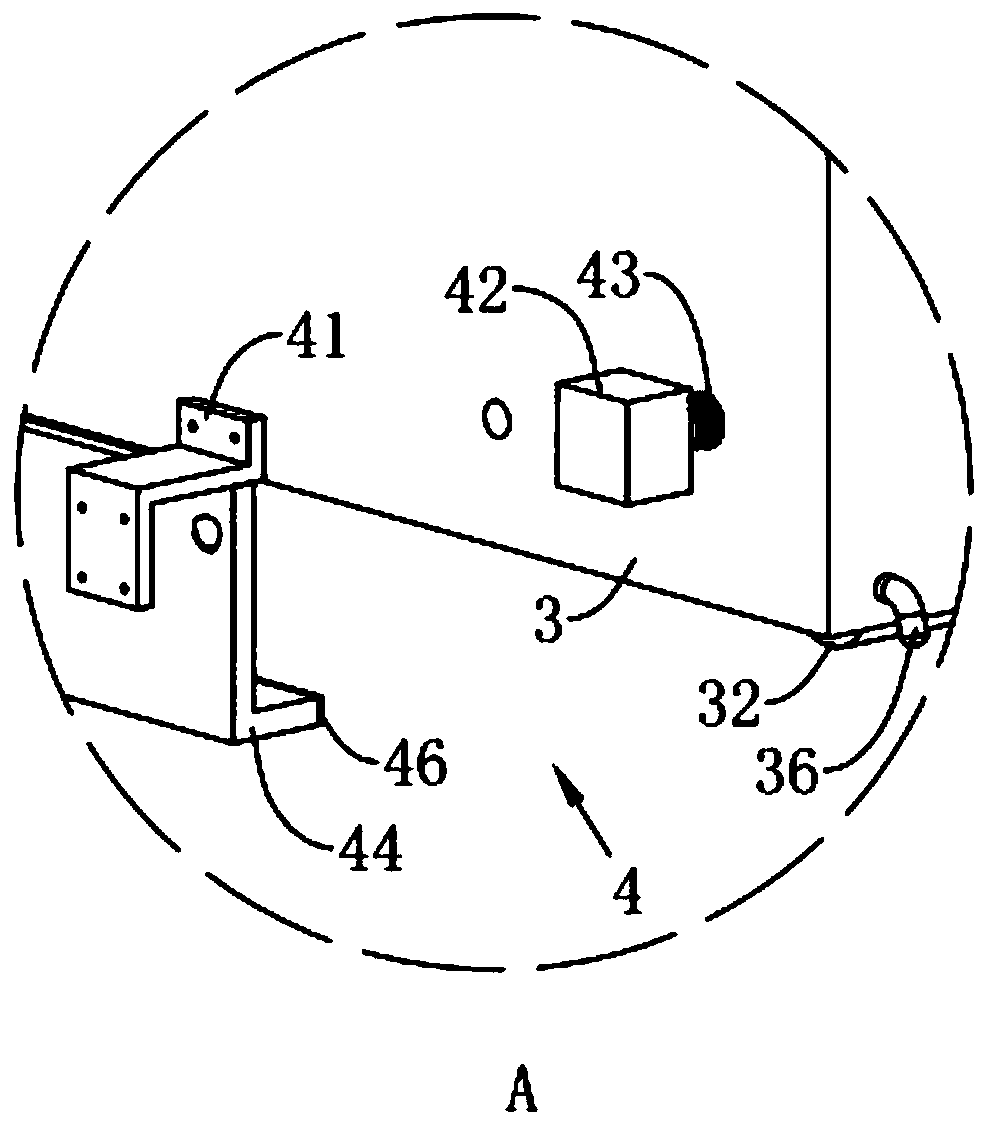

[0032] Reference figure 1 with figure 2 The multifunctional tile laying device shown includes a vertical cart 1, which is arranged in a similar "L" shape, and the push end of the vertical cart 1 is fixedly connected with two push handles 11, the push handle The surface of 11 is provided with a friction-enhancing anti-skid pattern 111. The vertical cart 1 is equipped with a lifting assembly 2 far away from its pushing end. The lifting assembly 2 is raised and lowered in the height direction of the vertical cart 1, and the lifting assembly 2 is detachably connected and placed A number of brick paving cylinders 3 stacked on top of each other. The shape of the paving cylinder 3 and the inner wall of the cylinder are all arranged in a square shape. Two of the opposite sides of the paving cylinder 3 are connected with each other in the paving cylinder 3. Groove 37, the through groove 37 communicates with the opening of the tile tube 3 facing the sealing plate 31, the channel of the t...

Embodiment 2

[0056] The difference between Embodiment 2 and Embodiment 1 is:

[0057] Reference Picture 11 As shown, the pusher 5 includes four guide rods 53 fixedly connected to the end surface of the sealing plate 31 away from the tile cylinder 3, the guide rods 53 and the sealing plate 31 are arranged in parallel to each other, and the end of the guide rod 53 away from the sealing plate 31 is fixedly connected and limited. Position block 531, the four guide rods 53 are plugged into the same second motor 54. The driving end of the second motor 54 rotates coaxially with threads penetrating the sealing plate 31 and facing the first lead screw 55 in the tile drum 3, pushing the plate 52 is rotatably connected to the end of the first screw 55 away from the second motor 54, and two opposite sides of the pressing plate 56 abut the inner wall of the tile drum 3. The vertical cart 1 is provided with a second button 16 for controlling the operation of the second motor 54 of the pushing member 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com