Novel P-type crystalline silicon battery structure and preparation process thereof

A technology of crystalline silicon battery and preparation process, applied in the direction of sustainable manufacturing/processing, circuit, photovoltaic power generation, etc., can solve the problems of high risk, long return on investment period, and incomplete localization of materials and equipment, and achieve quick results , low investment cost, and short upgrade cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

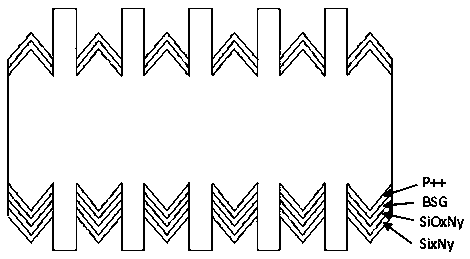

[0012] refer to figure 1 , a new P-type crystalline silicon battery structure and its preparation process. The back film layer structure is SixNy / SiOxNy / BSG / P++ from bottom to top, in which BSG / P++ is formed by boron diffusion, and the thickness of P++ layer is 100-200nm, which is close to The doping concentration on the back surface of the silicon substrate is 1x10 19 -5x10 19 / cm -3 Between, BSG film thickness is 3-5nm, doping concentration is 3x10 20 -5x10 20 / cm -3 ; The SixNy / SiOxNy film layer is deposited by PECVD equipment, the refractive index of SiOxNy is 1.7-2.0, the thickness is 3-5nm, the refractive index of SixNy is 2.1-2.3, the thickness is 120-150nm, and the total thickness of the stack is 125-155nm.

[0013] Concrete preparation process implementation process is as follows:

[0014] 1. Clean the velvet. Alkali texturing is used for texturing, the etching amount is controlled at 0.4-0.6g, and the reflectivity is 7%-12%.

[0015] 2. Diffusion knots.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com