Garment with joint bending electromagnetic induction power generation and its preparation method and application

A technology of electromagnetic induction and joint bending, applied in clothing, applications, electromechanical devices, etc., can solve the problems of poor flexibility, heavy weight, difficult to fiber or fabric, and achieve uniform distribution, good mechanical properties, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

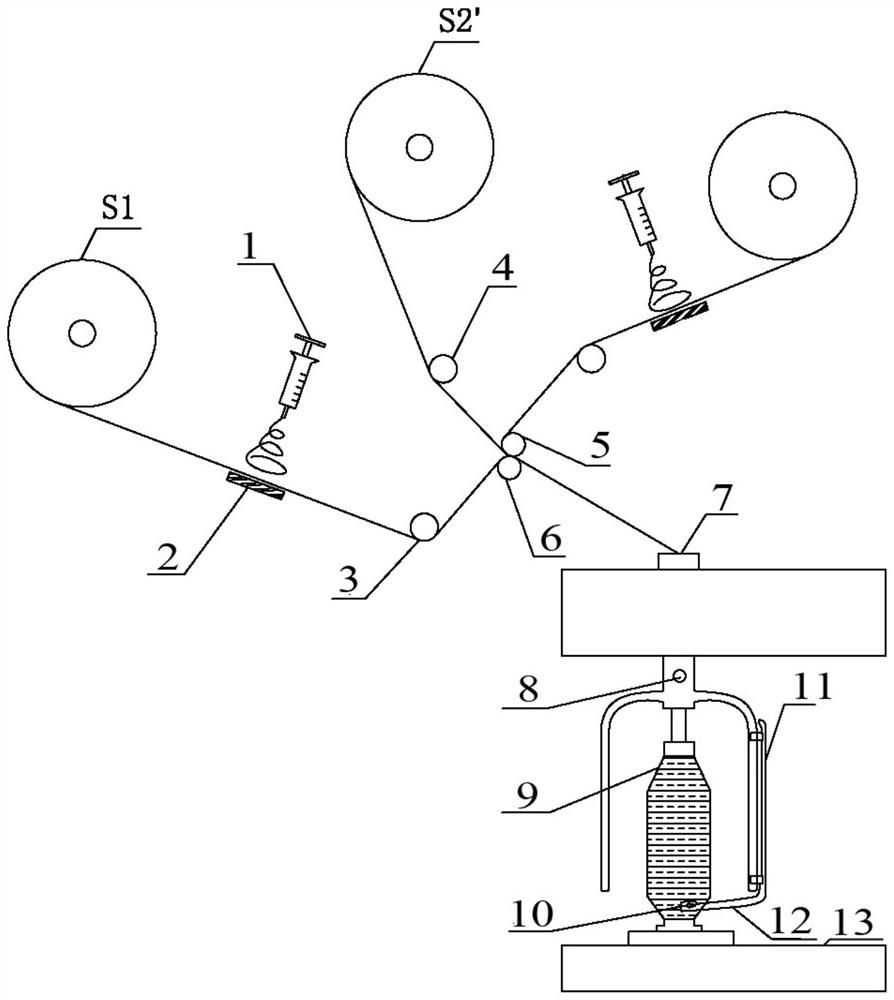

[0048] The invention provides a preparation method of a garment for joint bending electromagnetic induction power generation, comprising the following steps:

[0049] S1, preparation of flexible fiber strips S1: the non-woven flexible surface material with an area density of 2-100 g / m2 is cut into flexible fiber strips S1 with a linear density of 10-800 g / km;

[0050] S2, prepare composite fiber strip S2': demagnetize the magnetic powder, put the fiber strip S2 with a width of 10-20mm and a linear density of 10-1000 g / km into the reaction vessel, conduct electricity through in-situ polymerization polymer, a conductive polymer is grown on the fiber strip, and after pulling, drying and drying, a composite fiber strip with a conductive polymer is obtained; the composite fiber strip is immersed in the magnetic powder with a particle size of Padding treatment is performed in a dispersion liquid with a magnetic powder mass concentration of 10-1000 nm and a magnetic powder mass conce...

Embodiment 1

[0062] A garment for generating electricity by joint bending electromagnetic induction and a preparation method thereof, comprising the following steps:

[0063] S1, prepare the flexible fiber strip S1: cut the non-woven flexible surface material with an area density of 50 g / m2 into a flexible fiber strip S1 with a linear density of 400 g / km;

[0064] S2, preparation of composite fiber strip S2': demagnetize the magnetic powder, put the fiber strip S2 with a width of 10 mm and a linear density of 500 g / km into a reaction vessel, and polymerize the conductive polymer in situ. A conductive polymer is grown on the fiber strip, and after pulling, drying and drying, a composite fiber strip with a conductive polymer is obtained; the composite fiber strip is immersed in a magnetic powder with a particle size of 100 nm and a magnetic powder Padding treatment is performed in a dispersion liquid with a mass concentration of 10%, so that the magnetic powder in the dispersion liquid is sq...

Embodiment 2

[0077] A garment for generating electricity by joint bending electromagnetic induction and a preparation method thereof, comprising the following steps:

[0078] S1, prepare the flexible fiber strip S1: cut the non-woven flexible surface material with an area density of 100 g / m2 into a flexible fiber strip S1 with a linear density of 500 g / km;

[0079] S2, preparation of composite fiber strip S2': demagnetize the magnetic powder, put the fiber strip S2 with a width of 20 mm and a linear density of 400 g / km into a reaction vessel, and polymerize the conductive polymer in situ. A conductive polymer is grown on the fiber strip, and after pulling, drying and drying, a composite fiber strip with a conductive polymer is obtained; the composite fiber strip is immersed in a magnetic powder with a particle size of 500 nm and a magnetic powder Padding treatment is performed in a dispersion liquid with a mass concentration of 15%, so that the magnetic powder in the dispersion liquid is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com