Energy-saving distillation device of multifunctional lubricating oil production equipment

A technology for production equipment and distillation devices, which is used in distillation separation, lubricating composition, distillation energy recovery, etc., and can solve the problem of not having the function of over-collecting and reusing waste liquid, unable to filter, collect and store lubricating oil, and unclean exhaust gas discharge treatment, etc. problems, to avoid waste of thermal energy resources, facilitate operation, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

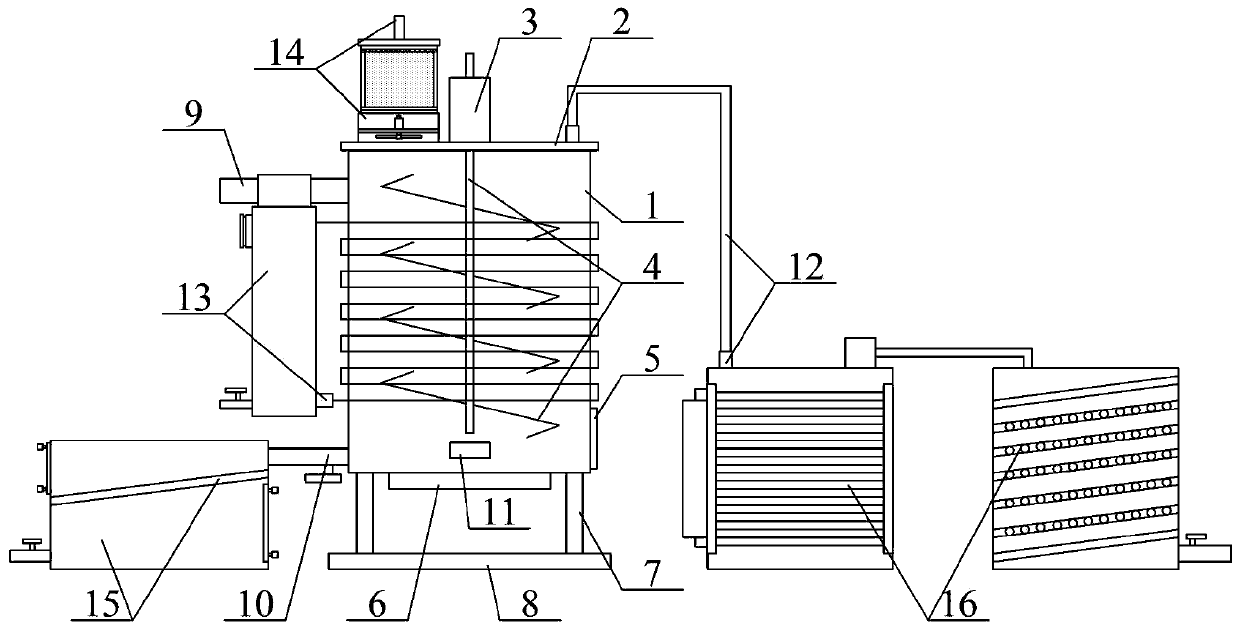

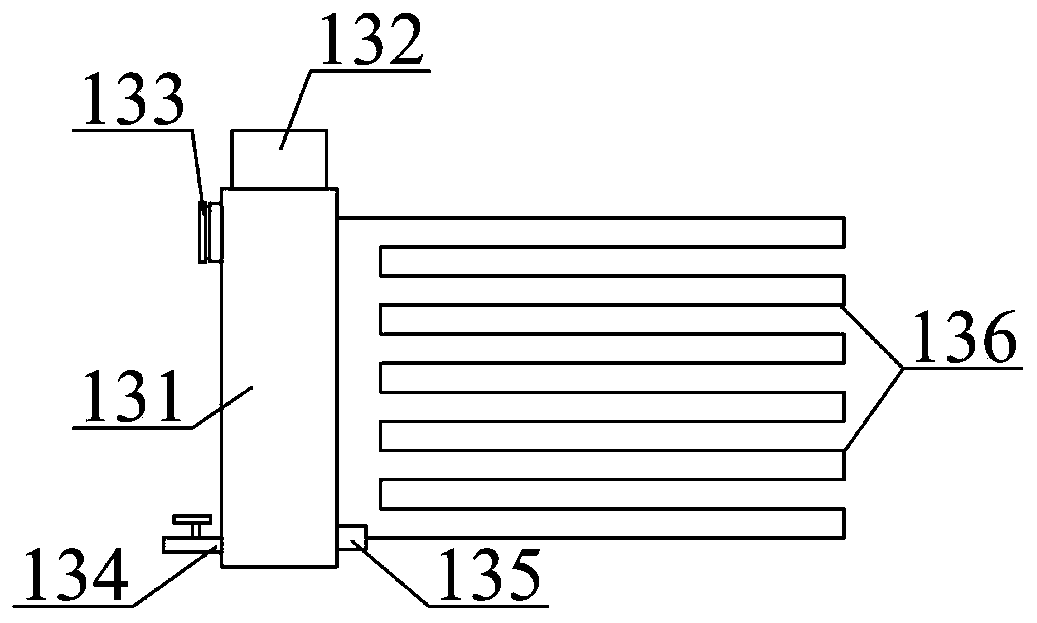

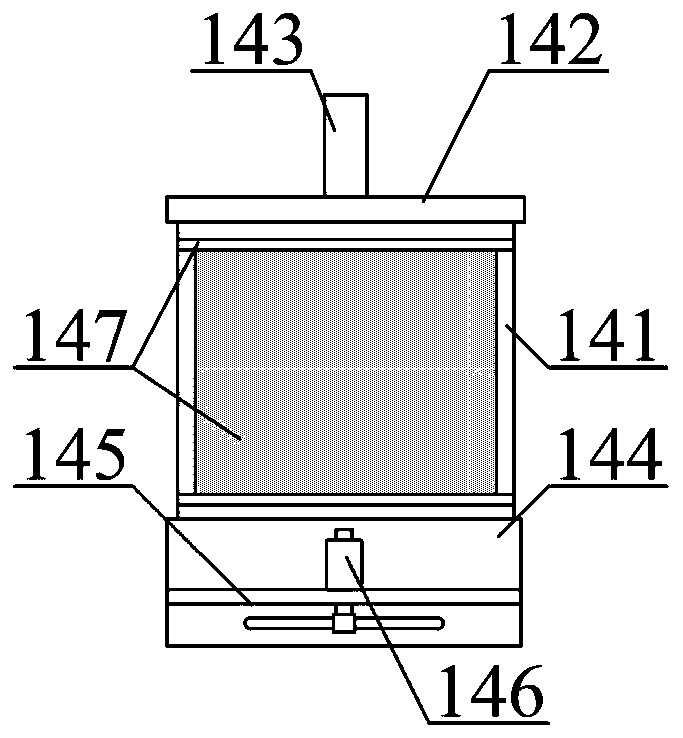

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the distillation device of the energy-saving multifunctional lubricating oil production equipment includes a distillation tank 1, a tank cover 2, a stirring motor 3, an auger 4, a control panel 5, a heater 6, a support leg 7, a fixed base 8, and a lubricating oil Conduit 9, oil discharge pipe with valve 10, temperature sensor 11, air guide pipe 12, waste heat-free reheating water supply tank structure 13, waste gas discharge and anti-fouling treatment cylinder structure 14, lubricating oil filtration and adsorption temporary storage tank structure after distillation 15 and waste gas condensation Liquefaction filtration reuse storage tank structure 16, the upper end of the distillation tank 1 is threadedly connected with a tank cover 2; the upper middle position of the tank cover 2 is longitudinally bolted with a stirring motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com